Bactericidal sustained-release microsphere and preparation method thereof

A technology of slow-release microspheres and polylactic acid, which is applied in the fields of botanical equipment and methods, fungicides, biocides, etc., can solve the problem of temperature-sensitive drugs, and the drug particle size is not well controlled, the particle drug load is low, and the drug is high. Stability and other issues, to achieve the effect of extensive research and application prospects, uniform particle size and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following technical solutions in the present invention will be described clearly and completely. Obviously, the described embodiments are part of the embodiments of the present invention, rather than all of them. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

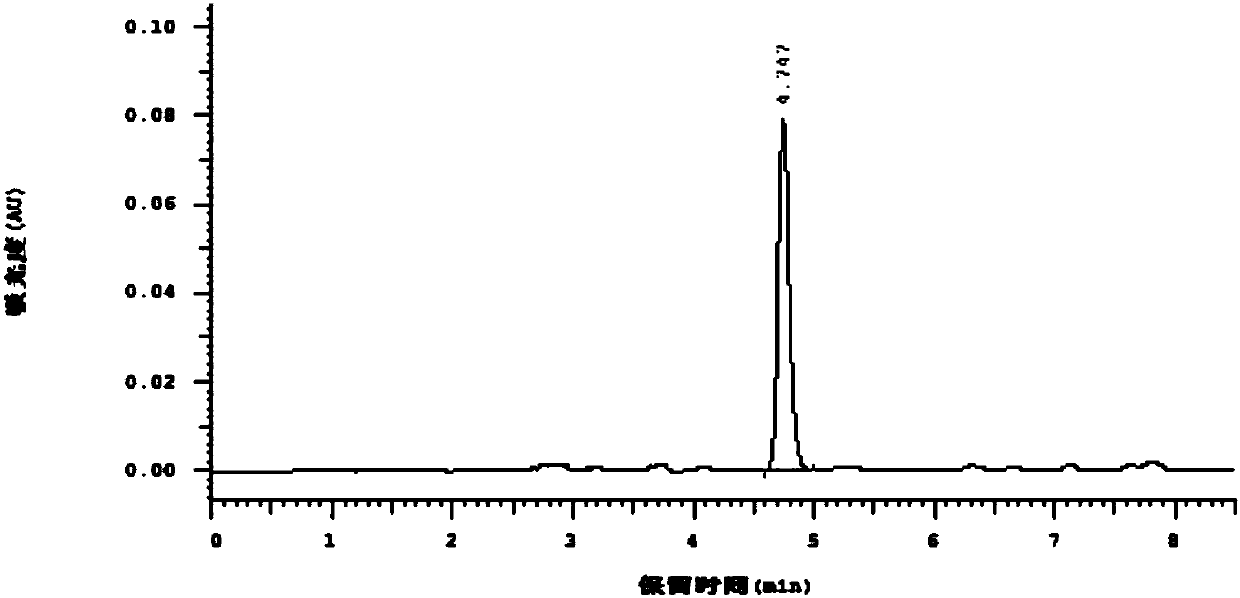

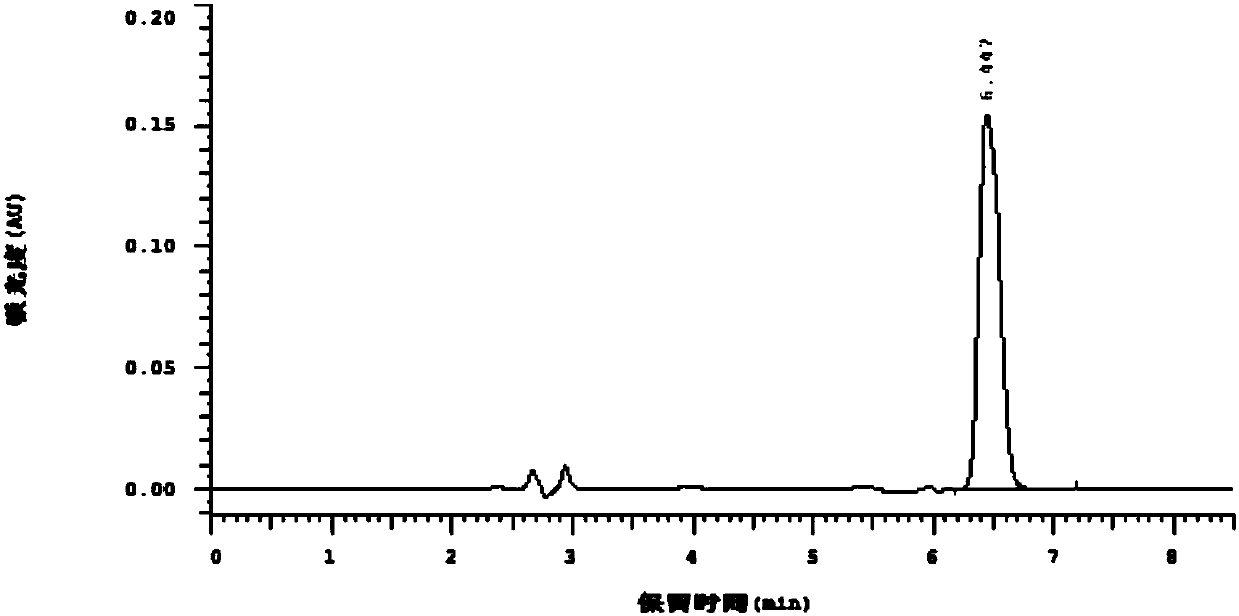

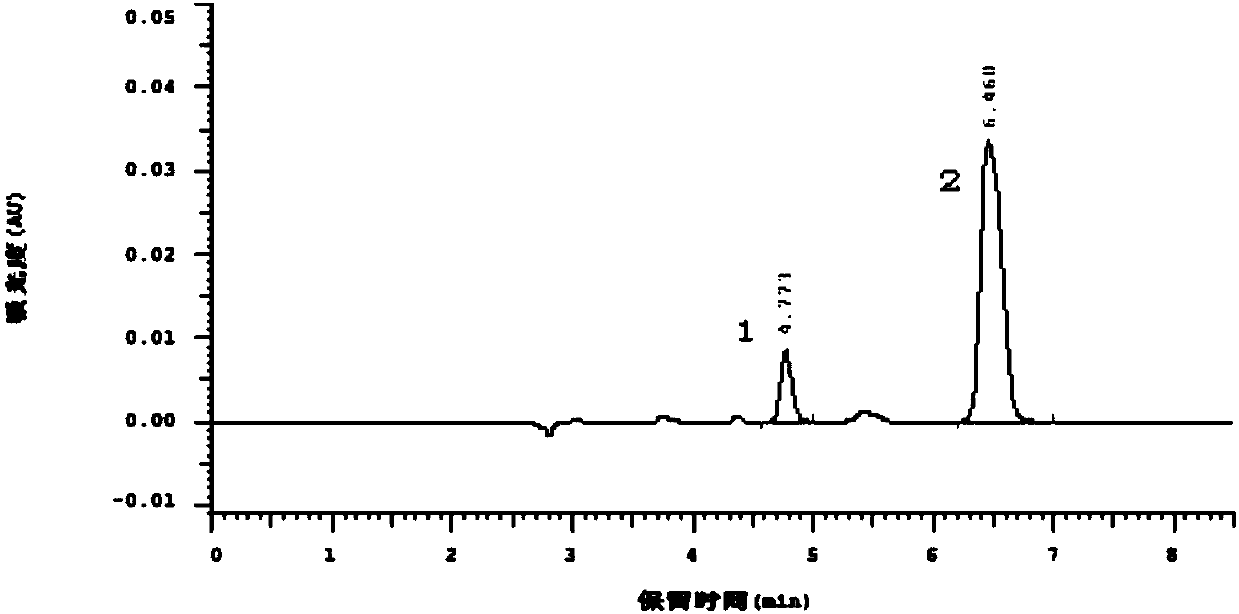

[0062] The invention uses difenoconazole and flusilazole as the core materials, polylactic acid as the wall material, and adopts the solvent volatilization method. The emulsification speed and time, emulsifier concentration, stirring speed and time, and the oil-water phase volume ratio are investigated through single factor tests. , The influence of the concentration of polylactic acid and the mass ratio of core-wall materials on the preparation of microsp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com