A preparation method of nano-rod-shaped zinc oxide and its application in the preparation of air-conditioning ventilation ducts

A nano-rod-shaped, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, paint containing biocide, etc., can solve the problems of easy aggregation of particles, surface defects, and restrictions on the development of nano-ZnO, and achieve good repeatability , surface integrity, improve the effect of self-cleaning and antibacterial and anti-mildew performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

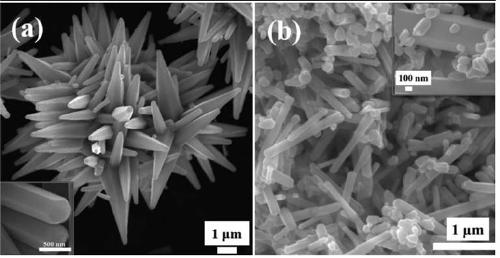

[0035] A preparation method of nanorod-shaped zinc oxide: comprising the following preparation steps:

[0036] 1) Preparation of alkali solution: the alkali solution is a glycerol solution of sodium borohydride, and the pH value of the alkali solution is 10-11;

[0037] 2) Mixed titration: at room temperature (20°C) and normal pressure (1.01×10 5 Pa), under stirring conditions, drop the alkali solution in step 1) into the 0.04M aqueous solution of zinc acetate dihydrate or zinc nitrate hexahydrate to form a gel, continue to titrate to form a white precipitate, and age for 3 to 24 hours , the white precipitate after aging is a uniform array of nanorods;

[0038] 3) Washing: filter and wash the white precipitate aged in step 2) several times with distilled water or absolute ethanol until the washing solution is neutral;

[0039] 4) Centrifugation: the washed white precipitate is centrifuged and vacuum-dried at room temperature (25° C.) to obtain the nanorod-shaped zinc oxide p...

Embodiment 2

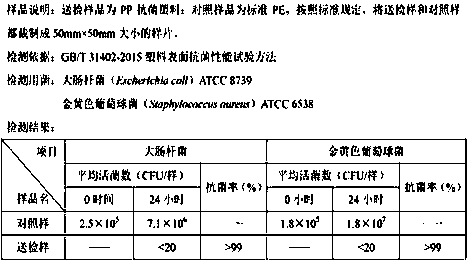

[0042] Antibacterial air-conditioning and ventilation plastic pipes were prepared using nanorod-shaped zinc oxide described in Example 1.

[0043] Include the following steps:

[0044] 1) Mix the nanorod-shaped zinc oxide powder with absolute ethanol to obtain a uniformly dispersed mixture, and the mass ratio of absolute ethanol to nanorod-shaped zinc oxide is 3.5:1;

[0045] 2) Prepare a mixed solution of Kh-560 silane coupling agent and absolute alcohol, the mass ratio of kh-560 silane coupling agent to absolute alcohol is 1:1.5;

[0046] 3) Add the mixed solution in step 2) dropwise to the mixture in step 1), stir and filter, and dry for 1-2 hours to obtain modified nano-zinc oxide;

[0047] 4) Mix the modified nano-zinc oxide with PP, PE, PVC, ABS and other plastic raw materials according to the mass ratio of 1; 2.5, extrude and granulate with a double-roll extruder to obtain plastic antibacterial masterbatch;

[0048] 5) The plastic antibacterial masterbatch is added to...

Embodiment 3

[0053] Antibacterial metal coatings were prepared using nanorod-shaped zinc oxide described in Example 1.

[0054] Add nano-rod-shaped zinc oxide to the aqueous solution of sodium lauryl sulfate dispersant (the mass ratio of nano-rod-shaped zinc oxide, sodium lauryl sulfate, and water is 1:5:40), and self-prepared liquid materials can be sprayed onto It can be used on metal ventilation pipes such as tin sheet and stainless steel to improve its self-cleaning and antibacterial properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com