A kind of preparation method of chromogenic antibacterial pork wrapping paper

A technology for wrapping paper and pork, applied in wrapping paper, wrapping paper, packaging, etc., can solve problems such as physical discomfort, poisoning, and heavy human subjective factors, and achieve the effects of eliminating odor, preventing spoilage, and prolonging storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

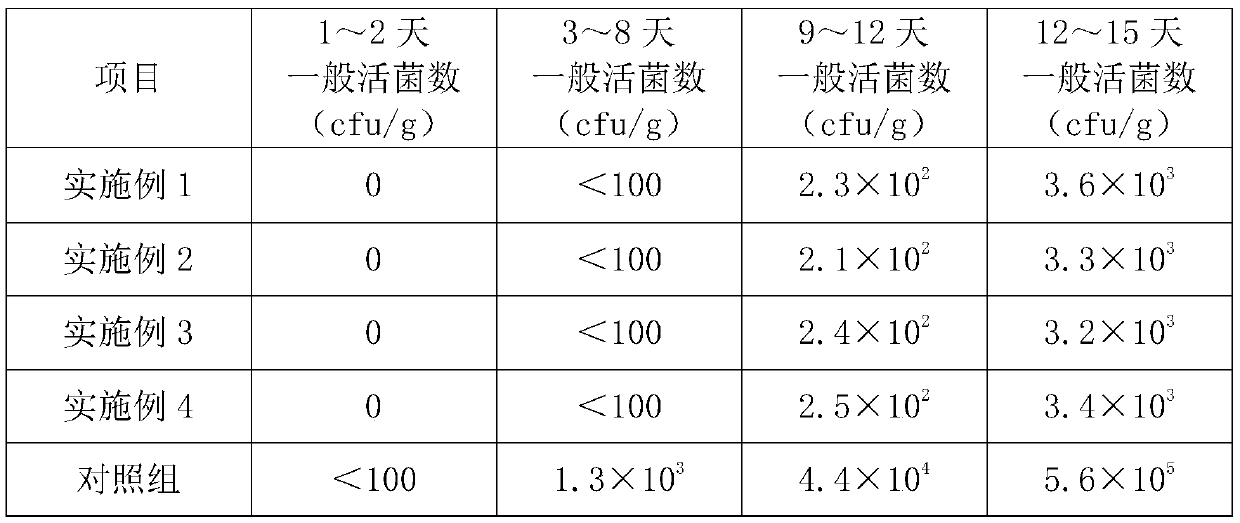

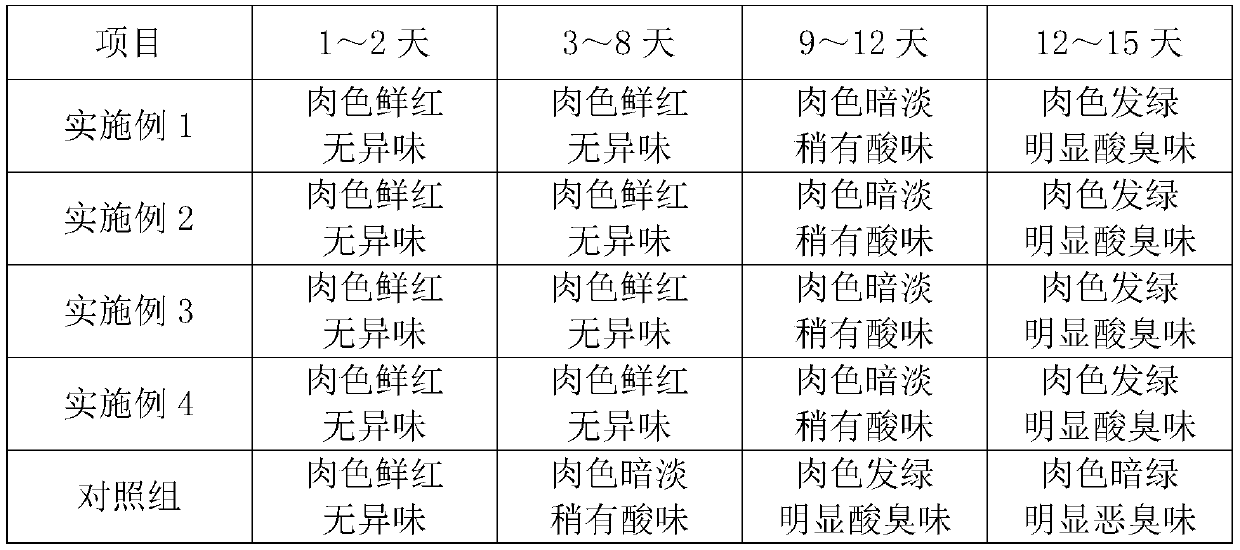

Examples

Embodiment 1

[0029] A preparation method of color-developing antibacterial pork wrapping paper, the specific steps of the preparation method are as follows:

[0030] (1) 1g micronomycin sulfate, 50g styrene, 8g hexadecane, 5g n-octane, 5g polyethylene glycol, 1000g, 15wt% sodium dihydrogen phosphate buffer were mixed, stirred evenly, emulsified for 20min, Ultrasonic dispersion in an ice bath for 20 minutes to obtain a monomer fine emulsion, and N was introduced into the monomer fine emulsion 2 , heat up to 80°C, add 5g of potassium persulfate to react for 2h, add 0.8g of acrylic acid to continue the reaction for 1h, carry out demulsification with saturated NaCl solution, then centrifuge, dry, and the particle size of the micronomycin sulfate nano-microcapsules obtained is 20~40nm;

[0031] (2) 10g porous silicon dioxide particles and 10g step (1) prepared micronomycin sulfate nano-microcapsules are added to 50g, in the Congo red solution of 1.0wt%, stirred at 40°C for 6h, cleaned, and bak...

Embodiment 2

[0037] A preparation method of color-developing antibacterial pork wrapping paper, the specific steps of the preparation method are as follows:

[0038] (1) 1g micronomycin sulfate, 58g styrene, 10g hexadecane, 6g n-octane, 8g polyethylene glycol, 1000g, 16wt% sodium dihydrogen phosphate buffer were mixed, stirred evenly, emulsified for 25min, Ultrasonic dispersion in an ice bath for 25 minutes to obtain a monomer fine emulsion, and N was introduced into the monomer fine emulsion 2 , heated up to 82°C, added 6g of potassium persulfate to react for 2.5h, added 1.0g of acrylic acid to continue the reaction for 1.2h, demulsified with saturated NaCl solution, then centrifuged, dried, and the obtained micronomycin sulfate nano-microcapsules The diameter is 20-40nm;

[0039] (2) 10g of porous silicon dioxide particles and 15g of micronomycin sulfate nanocapsules prepared in step (1) are added to 50g, in the Congo red solution of 2.0wt%, stirred at 45°C for 8h, cleaned, and baked dry...

Embodiment 3

[0045] A preparation method of color-developing antibacterial pork wrapping paper, the specific steps of the preparation method are as follows:

[0046] (1) 2g micronomycin sulfate, 110g styrene, 18g hexadecane, 11g n-octane, 12g polyethylene glycol, 2000g, 18wt% sodium dihydrogen phosphate buffer were mixed, stirred evenly, emulsified for 28min, Ultrasonic dispersion in an ice bath for 28 minutes to obtain a monomer fine emulsion, and N was introduced into the monomer fine emulsion 2 , heat up to 84°C, add 11g of potassium persulfate to react for 3h, add 1.8g of acrylic acid to continue the reaction for 1.5h, demulsify with a saturated NaCl solution, then centrifuge and dry, the particle size of the micronomycin sulfate nanocapsules obtained is 20-40nm;

[0047] (2) 20g porous silicon dioxide granule and 20g step (1) made micronomycin sulfate nano-microcapsules are added to 100g, in the Congo red solution of 1.5wt%, stir 10h at 50 ℃, clean, dry dry to obtain micronomycin su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com