Deep dewatering equipment and method for electrochemical sludge

A deep dehydration and electrochemical technology, applied in electrochemical sludge treatment, chemical instruments and methods, fixed/solidified sludge treatment, etc., can solve the problems of sludge increment, inability to remove heavy metals, high transportation costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

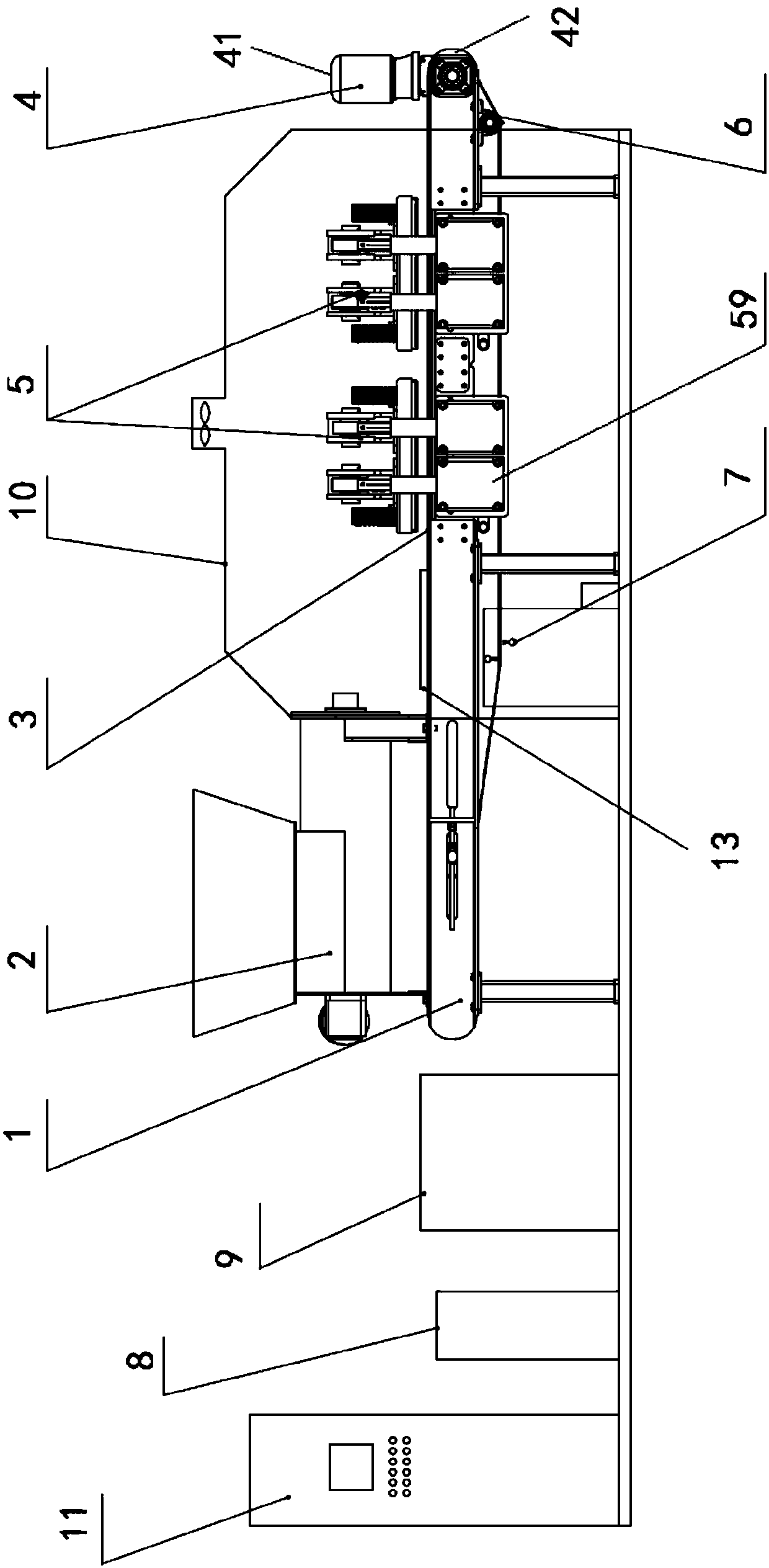

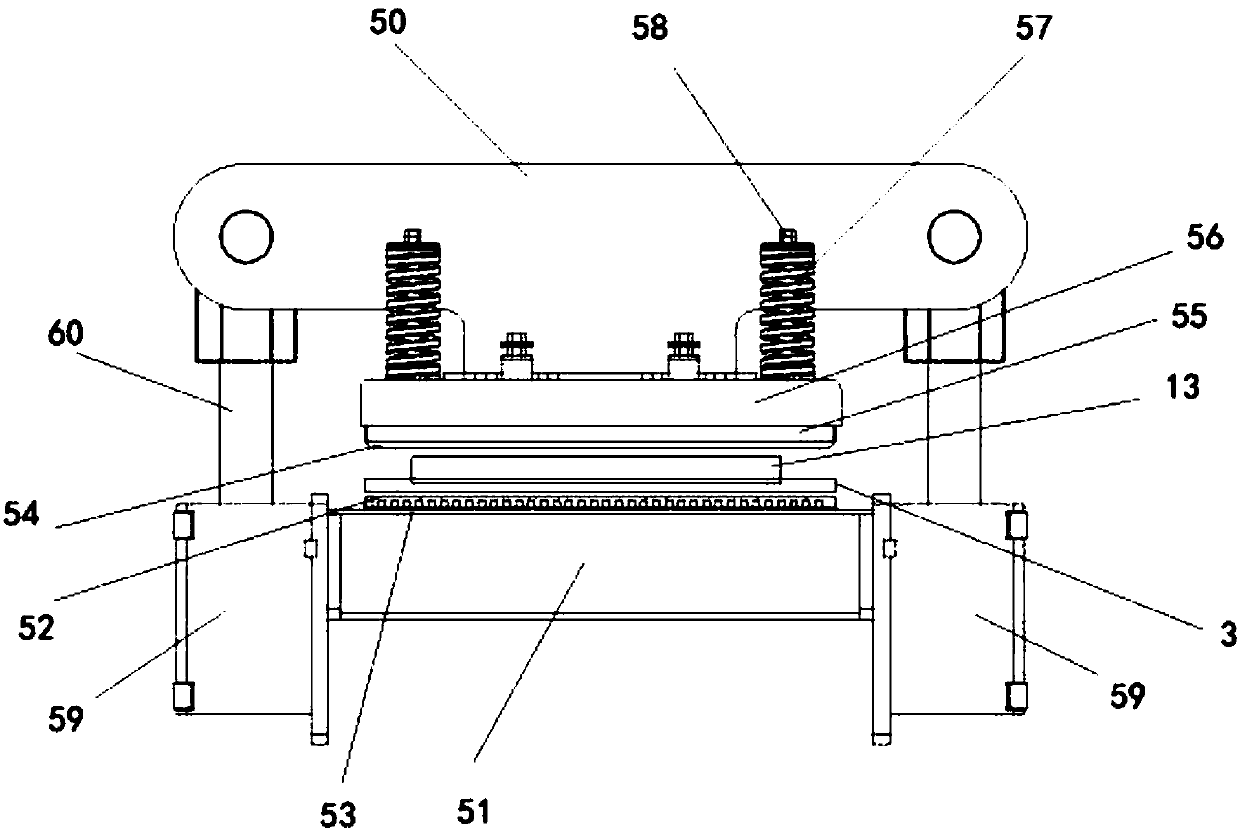

[0036] Such as Figure 1-Figure 5 As shown, the present invention is an electrochemical sludge deep dewatering device, which includes: a main frame 1, a feeder 2, a sludge conveyor belt 3, a conveyor belt driving mechanism 4, and a plurality of electrochemical sludge deep dewatering mechanisms connected in series 5. Mud cake separation mechanism 6. Sludge conveyor belt descaling and cleaning system 7. Special DC power supply 8. Power hydraulic station 9. Shell 10. Electrical control system 11.

[0037] The host frame 1 supports and fixes the entire device.

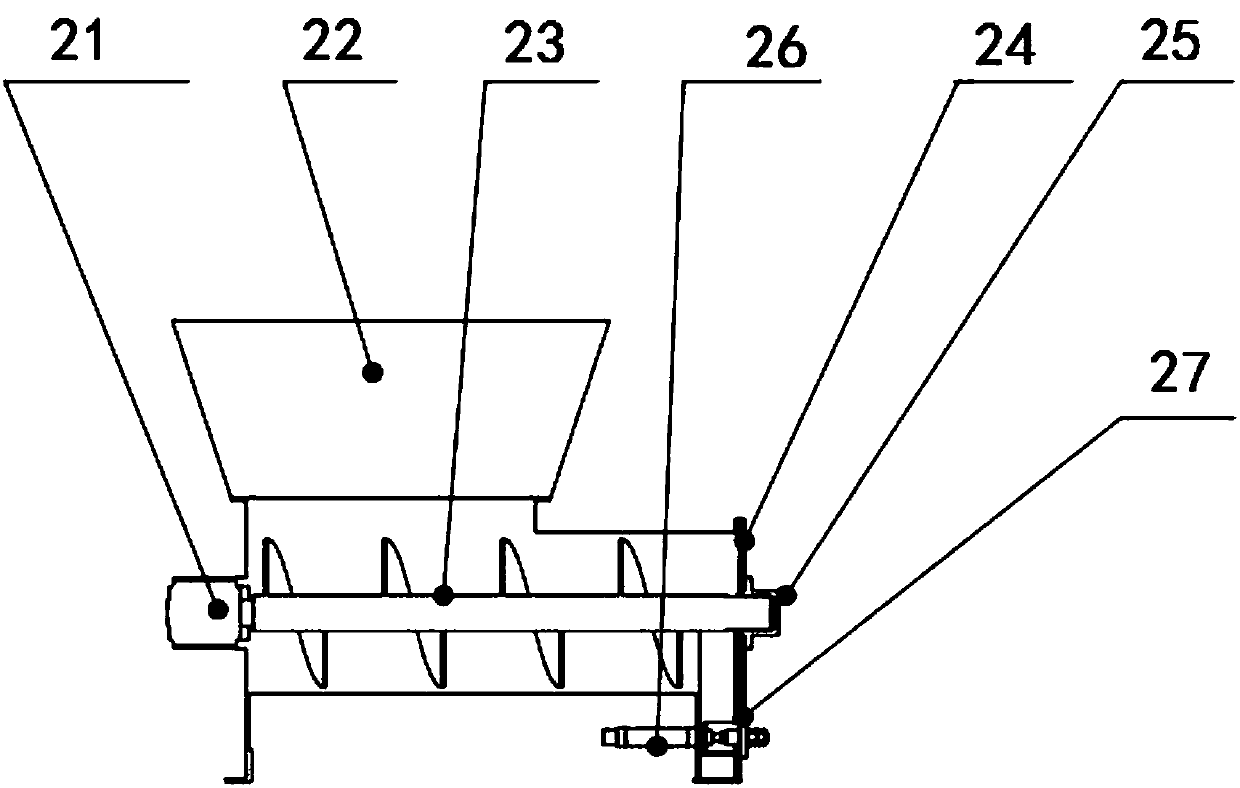

[0038] The feeder 2 is horizontally arranged directly above the front of the sludge conveyor belt 3, and is mainly composed of a drive motor 21, a silo 22, a screw 23, a blocking plate 24, a bearing 25, an adjustable stroke cylinder 26, and a valve 27. The feeder 2 has a cavity, the upper part of the front end of the cavity is provided with a feed bin 22, the screw rod 23 with blades is installed in the cavity through a b...

Embodiment 2

[0053] Such as Image 6 The shown electrochemical sludge deep dewatering equipment of the present invention adopts an upper and lower two-layer structure, that is, in order to increase the processing capacity and save space, an upper and lower layer as described in Example 1 is arranged in the same shell. A complete set of electrochemical sludge deep dewatering equipment (including: main frame 1, feeder 2, sludge conveyor belt 3, conveyor belt drive mechanism 4, two sets of electrochemical sludge deep dewatering mechanism 5 connected in series, mud cake separation mechanism 6 ), that is, each layer is equipped with two sets of electrochemical sludge deep dewatering mechanisms 5 connected in series. The upper layer is arranged on the lower layer through the supporting frame 12 . The parallel connection mode is adopted between the layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com