PETG/dendritic phthalocyanine-loaded SiO2 composite wire with photocatalytic effect, and preparation method thereof

A composite wire and dendritic technology, applied in the field of PETG/dendritic phthalocyanine loaded SiO2 composite wire and its preparation, achieves the effect of simple and efficient preparation method, good visible light photocatalytic performance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

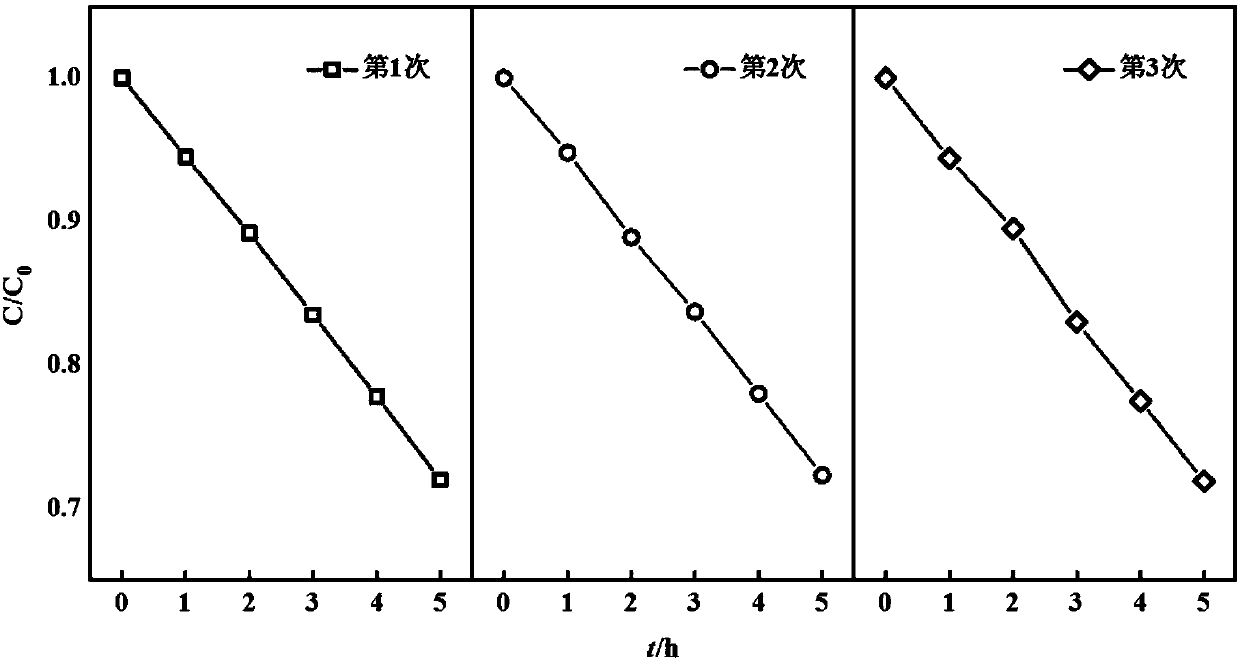

Examples

Embodiment 1

[0029] 1. A PETG / dendritic phthalocyanine loaded SiO with photocatalytic effect 2 The composite wire rod is characterized in that, according to the weight percentage, the formula is as follows:

[0030] PETG 53

[0031] PVA 20

[0032] 1-3 Generation Aryl Ether Dendritic Phthalocyanine Complex Supporting SiO 2 16

[0033] Ethylene glycol 7

[0035] stearic acid 1.

[0036] 2. The above-mentioned PETG / dendritic phthalocyanine loaded SiO with photocatalytic effect 2 A method for preparing a composite wire, comprising the steps of:

[0037] A. Vacuum-dry PETG and magnesium hydroxide respectively, and then load PETG, PVA, ethylene glycol, magnesium hydroxide, stearic acid and 1-3 aryl ether dendritic phthalocyanine complexes on SiO 2 Accurately weigh the formula according to the weight percentage, and then place the weighed components in a high-speed mixer and mix them evenly to obtain a mixture;

[0038] B. Melt and extrude the mixed mater...

Embodiment 2

[0043] 1. A PETG / dendritic phthalocyanine loaded SiO with photocatalytic effect 2 The composite wire rod is characterized in that, according to the weight percentage, the formula is as follows:

[0044] PETG69

[0045] PVA 12

[0046] 1-3 Generation Aryl Ether Dendritic Phthalocyanine Complex Supporting SiO 2 12

[0047] Glycerin 4

[0048] Magnesium hydroxide 2

[0049] Polyethylene wax 1.

[0050] 2. The above-mentioned PETG / dendritic phthalocyanine loaded SiO with photocatalytic effect 2 A method for preparing a composite wire, comprising the steps of:

[0051] A. Vacuum dry PETG and magnesium hydroxide respectively, and then load PETG, PVA, glycerin, magnesium hydroxide, polyethylene wax and 1-3 aryl ether dendritic phthalocyanine complexes on SiO 2Accurately weigh the formula according to the weight percentage, and then place the weighed components in a high-speed mixer and mix them evenly to obtain a mixture;

[0052] B. Melt and extrude the mixture through a t...

Embodiment 3

[0055] 1. A PETG / dendritic phthalocyanine loaded SiO with photocatalytic effect 2 The composite wire rod is characterized in that, according to the weight percentage, the formula is as follows:

[0056] PETG 55

[0057] PVA 18

[0058] 1-3 Generation Aryl Ether Dendritic Phthalocyanine Complex Supporting SiO 2 16

[0059] Polyethylene glycol 6.5

[0061] Oxidized polyethylene wax 1.5.

[0062] 2. The above-mentioned PETG / dendritic phthalocyanine loaded SiO with photocatalytic effect 2 A method for preparing a composite wire, comprising the steps of:

[0063] A. Vacuum dry PETG and calcium oxide respectively, and then load SiO with PETG, PVA, polyethylene glycol, calcium oxide, oxidized polyethylene wax and 1-3 generation aryl ether dendritic phthalocyanine complex 2 Accurately weigh the formula according to the weight percentage, and then place the weighed components in a high-speed mixer and mix them evenly to obtain a mixture;

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com