Method for electrochemically synthesizing lactone

An electrochemical and lactone technology, applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of unfavorable industrial operation, large-scale production, cumbersome process, etc., and achieve the effect of easy control, simple process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

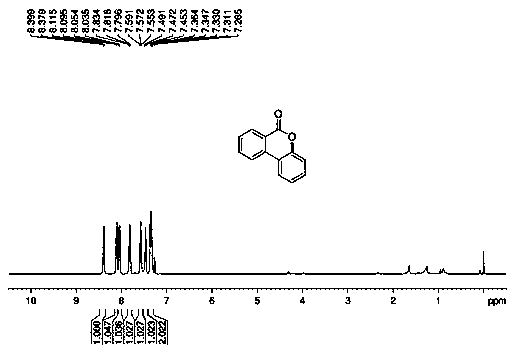

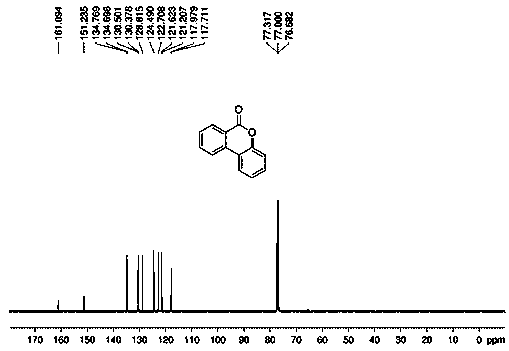

[0051] (1) Add 40g of raw material 2-phenylbenzoic acid (1aa), 6.6g of electrolyte tetra-n-butylammonium tetrafluoroborate and 50mL of solvent acetonitrile into the non-diaphragm electrolyzer, then insert the graphite electrode with a current density of 20mA / cm 2 Constant current at 20 o Stirring reaction at C;

[0052] (2) Follow the reaction by thin-layer chromatography. After the reaction is completed, spin off the solvent under vacuum, and then isolate the lactone product by recrystallization. H -Benzo[c]chroman-6-one (2aa) 33g, yield 84%.

[0053] 1 H NMR (400 MHz, CDCl 3 ): δ 8.40-8.38 (d, J = 7.9 Hz, 1H), 8.11-8.09(d, J = 8.0 Hz, 1H), 8.05-8.03 (d, J = 7.8 Hz, 1H), 7.83-7.80 (t, J = 7.6 Hz, 1H), 7.59-7.55 (t, J = 7.6 Hz, 1H), 7.49-7.45 (t, J = 7.7 Hz, 1H), 7.36-7.31(m, 2H); 13 C NMR (100 MHz, CDCl 3 ): δ 161.1, 151.2, 134.8, 134.7, 130.5, 130.4, 128.8, 124.5, 122.7, 121.6, 121.2, 118.0, 117.7.

Embodiment 2

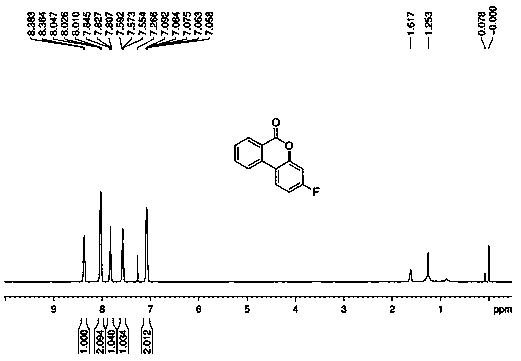

[0055] (1) Add 108mg of raw material 2-(4-fluorophenyl)benzoic acid (1ab), 342mg of electrolyte tetra-n-butylammonium perchlorate and 10mL of solvent acetone into the non-diaphragm electrolytic cell, and then insert the platinum electrode. Incoming current density is 10mA / cm 2 Constant current at 5 o Stirring reaction at C;

[0056] (2) Follow the reaction by thin layer chromatography. After the reaction is completed, spin off the solvent under vacuum, and then separate the lactone product 3-fluoro-6 by silica gel column chromatography. H -Benzo[c]chroman-6-one (2ab) 67mg, the yield is 63%.

[0057] 1 H NMR (400 MHz, CDCl 3 ): δ 8.38-8.36 (d, J = 7.8 Hz, 1H), 8.05-8.01(m, 2H), 7.85-7.81 (t, J = 7.6 Hz, 1H), 7.59-7.55 (t, J = 7.5 Hz, 1H), 7.09-7.06 (m, 2H); 13 C NMR (100 MHz, CDCl 3 ): δ 164.7-162.2 (d, J F-C = 249.6 Hz), 160.7, 152.2-152.1 (d, J F-C = 12.5 Hz), 135.0, 134.2, 130.6, 128.7, 124.4-124.3 (d, J F-C = 9.8 Hz), 121.5, 120.4, 114.6, 112.5-112.3 (d, J F-C = 22.2 H...

Embodiment 3

[0059] (1) Add 123mg of raw material 2-(4-methylphenyl)-4-chlorobenzoic acid (1ar), 660mg of electrolyte tetraethylammonium tetrafluoroborate and 50mL of solvent ethanol into the non-diaphragm electrolytic cell, and then insert Platinum electrode with current density of 13.3mA / cm 2 Constant current at 50 o Stirring reaction at C;

[0060] (2) Follow the reaction by thin layer chromatography. After the reaction is completed, spin off the solvent under vacuum, and then separate the lactone product 3-methyl-9-chloro-6 by silica gel column chromatography. H -Benzo[c]chroman-6-one (2ar) 55mg, the yield is 45%.

[0061] 1 H NMR (400 MHz, CDCl 3 ): δ 8.34 (d, J = 1.7 Hz, 1H), 8.02-8.00 (d, J =8.6 Hz, 1H), 7.89-7.87 (d, J = 8.5 Hz, 1H), 7.75-7.73 (dd, J = 8.6 Hz, 1.9Hz, 1H), 7.17-7.15 (d, J = 7.0 Hz, 2H), 2.45 (s, 3H); 13 C NMR (100 MHz, CDCl 3 ): δ160.3, 151.1, 141.8, 135.0, 134.4, 133.5, 130.0, 125.9, 123.1, 122.5, 122.2, 118.0, 114.7, 21.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com