Preparation method of nanofiber lithium titanate composite material

A technology of fiber lithium titanate and composite materials, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, electrical components, etc., can solve the problems of lithium titanate ion conductivity and poor electronic conductivity, and achieve high electronic and Ionic conductivity, high rate performance, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

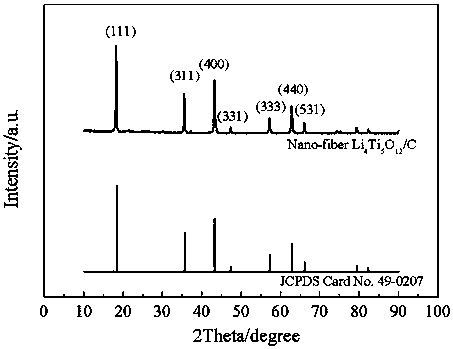

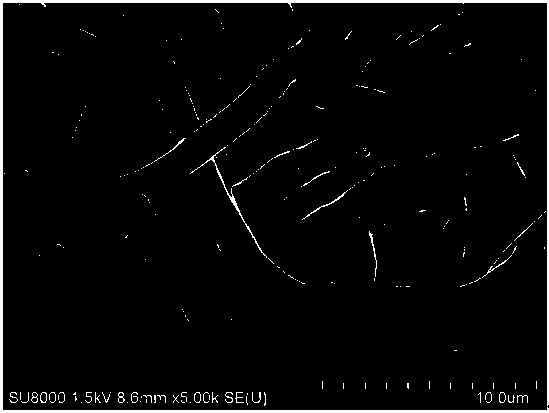

[0028] Add 1.75g of polyvinylpyrrolidone into 8.45g of ethanol, and stir to form a stable polyvinylpyrrolidone / ethanol sol. According to Li:Ti=4.4:5 molar ratio, add 5.00g tetrabutyl titanate and 1.32g lithium acetate to 5.63g ethanol, and add 4.63g acetic acid, stir until the solution is clear, add this solution to polyvinylpyrrolidone / ethanol sol, stirred for 5 h, and ultrasonically dispersed for 0.5 h to obtain an electrospinning precursor. An electrospinning machine was used for electrospinning, the spinning speed was 2mL / h, the electrostatic voltage was 25kV, and the distance between the receiving plate was 20cm to obtain the electrospinning precursor film. The precursor film was sintered at 750 °C for 3 h under the protection of argon, as figure 1 Nanofiber lithium titanate / carbon is obtained as shown.

Embodiment 2

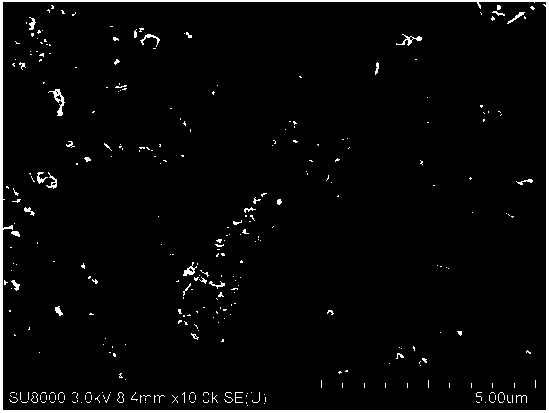

[0030] Such as Figure 2-5As shown, 1.75g of polyvinylpyrrolidone was added into 8.45g of ethanol, and stirred to form a stable polyvinylpyrrolidone / ethanol sol. According to Li:Ti=4.4:5 molar ratio, add 5.00g tetrabutyl titanate and 1.32g lithium acetate to 5.63g ethanol, and add 4.63g acetic acid, stir until the solution is clear, add this solution to polyvinylpyrrolidone / ethanol sol, stirred for 5 h, added 0.08 g of graphene, and ultrasonically dispersed for 1 h to obtain a graphene-doped lithium titanate sol precursor. An electrospinning machine was used for electrospinning, the spinning speed was 2mL / h, the electrostatic voltage was 25kV, and the distance between the receiving plate was 20cm to obtain the electrospinning precursor film. The precursor film was sintered at 750°C for 3h under the protection of argon to obtain the nanofiber lithium titanate / carbon / graphene composite material. According to the mass ratio of 85:10:5, the negative electrode active material ...

Embodiment 3

[0032] Add 1.75g of polyvinylpyrrolidone into 8.45g of ethanol, and stir to form a stable polyvinylpyrrolidone / ethanol sol. According to Li:Ti=4.4:5 molar ratio, add 5.00g tetrabutyl titanate and 1.32g lithium acetate to 5.63g ethanol, and add 4.63g acetic acid, stir until the solution is clear, add this solution to polyvinylpyrrolidone / ethanol sol, stirred for 5 h, added 0.16 g of graphite oxide, and ultrasonically dispersed for 1 h to obtain a lithium titanate sol precursor doped with graphite oxide. An electrospinning machine was used for electrospinning, the spinning speed was 2mL / h, the electrostatic voltage was 25kV, and the distance between the receiving plate was 20cm to obtain the electrospinning precursor film. The precursor film was sintered at 750°C for 3h under the protection of argon to obtain the nanofiber lithium titanate / carbon / graphene composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com