Technology for firing cement clinker by utilizing molten slag liquid phase of blast furnace

A technology for cement clinker and molten slag, applied in cement production and other directions, can solve problems such as high energy consumption and environmental pollution, and achieve the effects of reducing dust emissions, short process flow, and reducing greenhouse gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

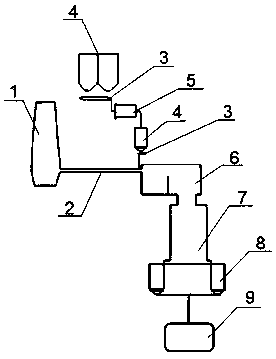

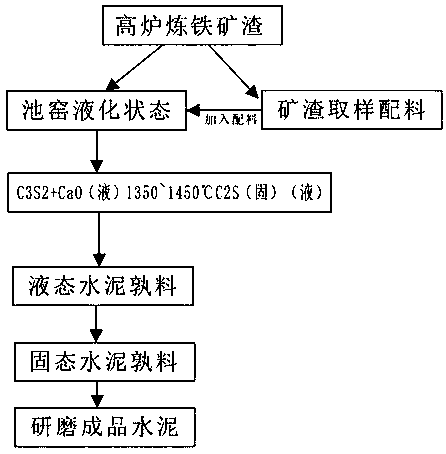

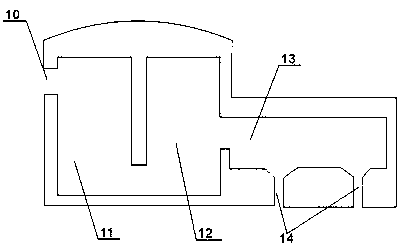

Method used

Image

Examples

example 1

[0078] Example 1: Production of ordinary cement clinker with Baosteel blast furnace liquid slag

[0079] chemical composition

SiO2

CaO

MgO

Fe2O3

Al2O3

TO2

MnO

SO3

liquid slag

32.99%

40.22%

7.77%

2.29%

14.62%

0.44%

0.4%

o.14%

activated lime

0.84%

94.5%

0.64%

37.06%

2.83%

2.71%

51.75%

6.32%

[0080] Add quicklime 87.37% and iron powder 14% to one ton of liquid slag

[0081] Lime saturation coefficient 0.96; iron rate 1.1

[0082] Product clinker chemical composition:

[0083] SiO2:20%; CaO:63.79%; Al2O3:7.75%; Fe2O3:4.76%; MgO:4.41%

example 2

[0084] Example 2: Production of ordinary cement clinker with Baosteel blast furnace liquid slag and liquid steel slag

[0085] chemical composition

SiO2

CaO

MgO

Fe2O3

Al2O3

TO2

MnO

SO3

liquid slag

32.99%

40.22%

7.77%

2.29%

14.62%

0.44%

0.4%

o.14%

activated lime

0.84%

94.5%

0.64%

liquid steel slag

8.64%

44.55%

7.59%

15.05%

1.48%

FeO17.78%

54.50%

2.31%

1.60%

7.34%

25.32%

[0086] Add 60% of liquid steel slag, 10% of fly ash and 93% of quicklime to one ton of blast furnace liquid slag;

[0087] Lime saturation coefficient: 0.96 Iron rate: 1.49

[0088] Product clinker chemical composition

[0089] SiO2: 18.44%; CaO: 62.45%; Al2O3: 7.21%; Fe2O3: 4.82%; MgO: 5.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com