Preparation method of cathode functional interlayer applied to lithium-sulfur battery

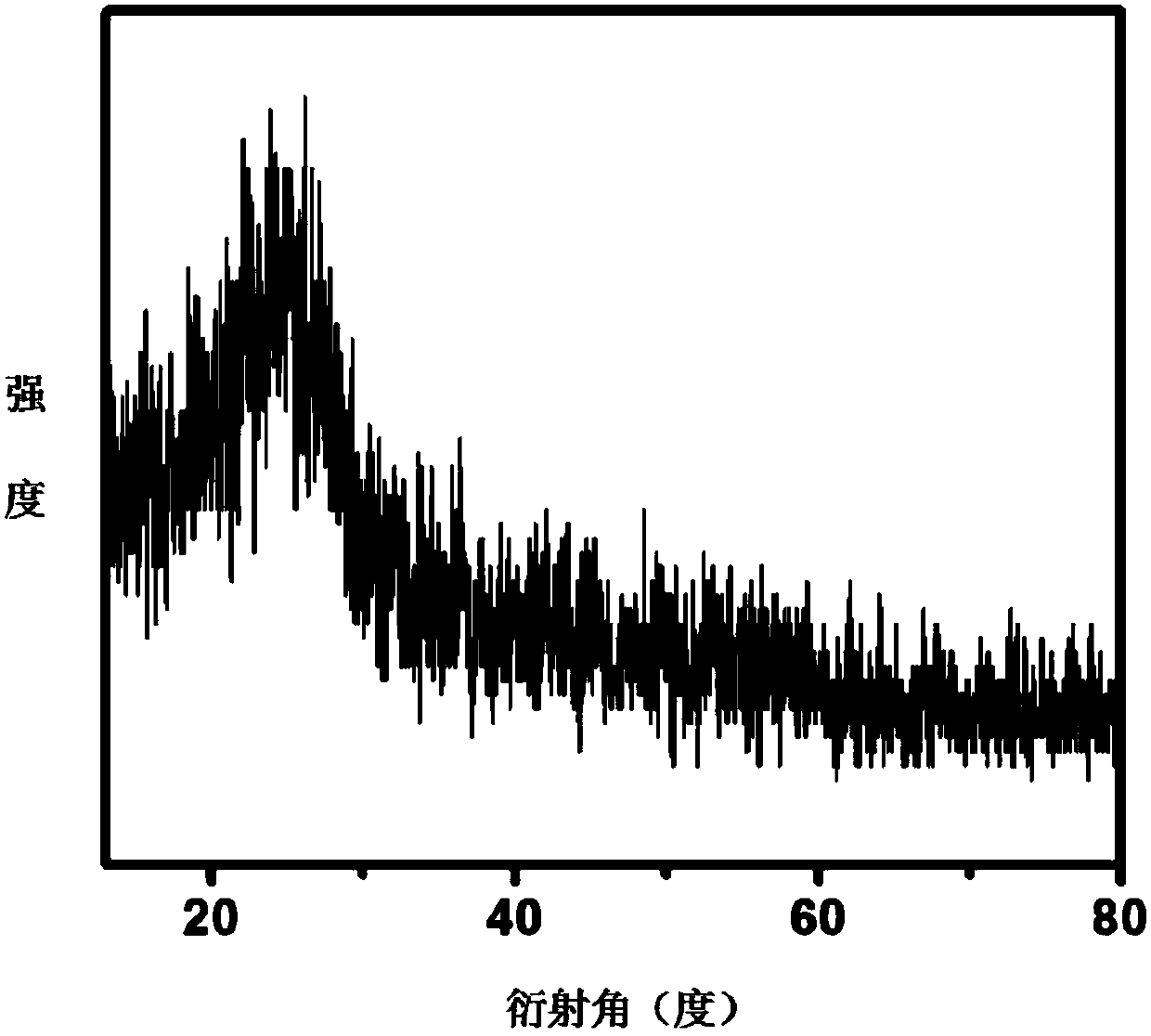

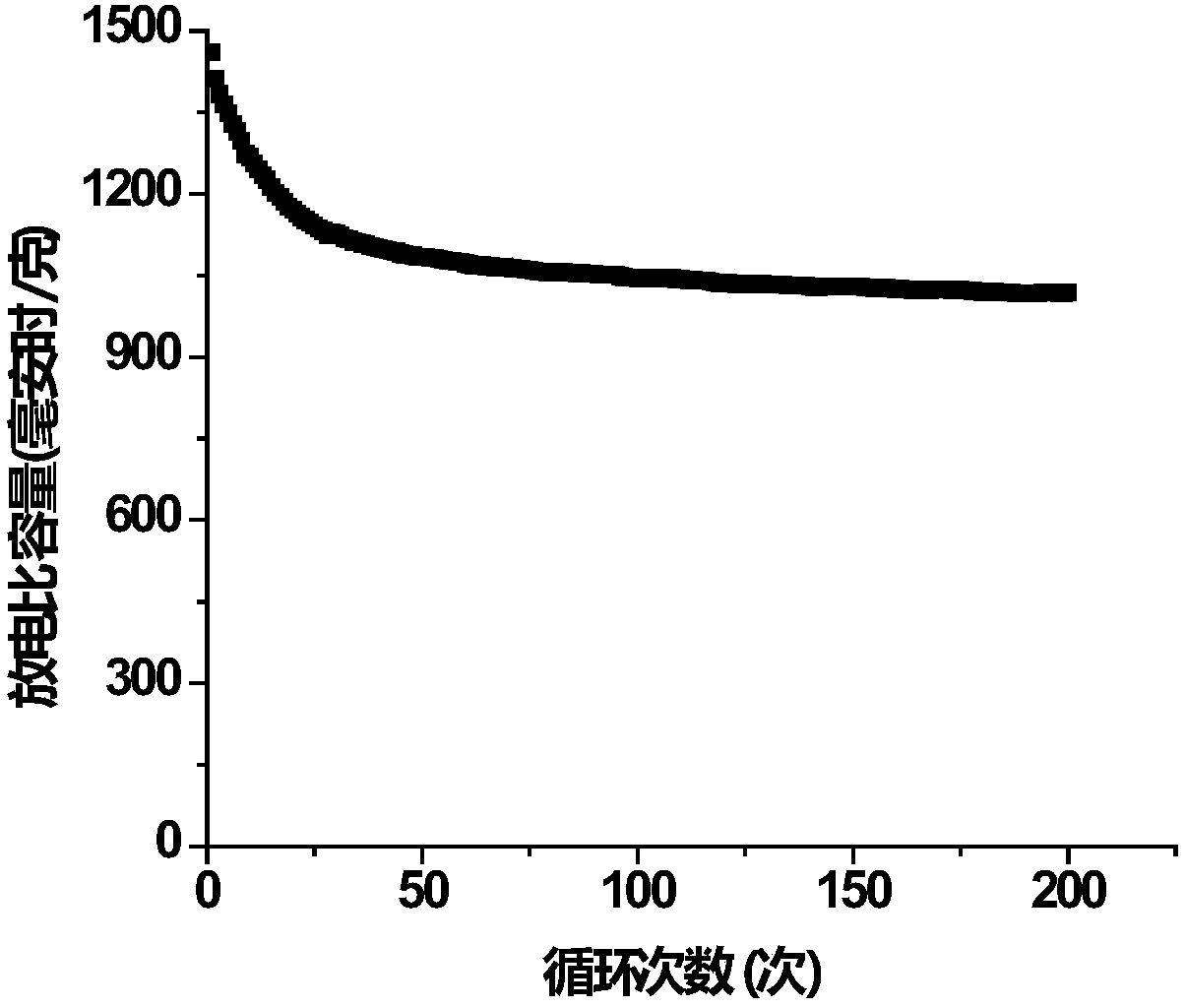

A lithium-sulfur battery and functional technology, applied in the field of preparation of positive functional separators, can solve the problems of low utilization rate of active materials, poor performance of lithium-sulfur batteries, etc., achieve rich pores, improve the shuttle effect of polysulfides, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0029] The first step, preparation of electrospun PAN membrane:

[0030] The PAN powder and the DMF solution were mixed at a mass ratio of 1:9, sealed and placed in a constant temperature water bath at 65°C for 24 hours with mechanical stirring to obtain an electrospinning solution. Fix the syringe with PAN / DMF solution on the micropump, adjust the distance between the needle tip and the receiving cylinder to the set distance of 25cm, start the motor, set the speed at 1000r / min, turn on the high voltage power supply and adjust to the set A good voltage is 15KV to check whether the spinning is in progress. After 24 hours of spinning, the high-voltage electrospinning device was turned off, and the spun fiber membrane was cut into sealed bags for later use.

[0031] The second step, pre-heat treatment of electrospun PAN membrane:

[0032] The PAN electrospun membrane is pre-heated in a muffle furnace. First, the temperature is raised from room temperature to 120°C at 3°C / min, t...

Embodiment example 2

[0036] The first step, preparation of electrospun PAN membrane:

[0037] The PAN powder and the DMF solution were mixed at a mass ratio of 1:9, sealed and placed in a constant temperature water bath at 65°C for 24 hours with mechanical stirring to obtain an electrospinning solution. Fix the syringe with PAN / DMF solution on the micropump, adjust the distance between the needle tip and the receiving cylinder to the set distance of 25cm, start the motor, set the speed at 1000r / min, turn on the high voltage power supply and adjust to the set A good voltage is 15KV to check whether the spinning is in progress. After 24 hours of spinning, the high-voltage electrospinning device was turned off, and the spun fiber membrane was cut into sealed bags for later use.

[0038] The second step, pre-heat treatment of electrospun PAN membrane:

[0039] The PAN electrospun membrane is pre-heated in a muffle furnace. First, the temperature is raised from room temperature to 120°C at 3°C / min, t...

Embodiment example 3

[0043] The first step, preparation of electrospun PAN membrane:

[0044] The PAN powder and the DMF solution were mixed at a mass ratio of 1:9, sealed and placed in a constant temperature water bath at 65°C for 24 hours with mechanical stirring to obtain an electrospinning solution. Fix the syringe with PAN / DMF solution on the micropump, adjust the distance between the needle tip and the receiving cylinder to the set distance of 25cm, start the motor, set the speed at 1000r / min, turn on the high voltage power supply and adjust to the set A good voltage is 15KV to check whether the spinning is in progress. After 24 hours of spinning, the high-voltage electrospinning device was turned off, and the spun fiber membrane was cut into sealed bags for later use.

[0045] The second step, pre-heat treatment of electrospun PAN membrane:

[0046] The PAN electrospun membrane is pre-heated in a muffle furnace. First, the temperature is raised from room temperature to 120°C at 3°C / min, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com