Magnesium alloy and aluminum alloy connecting method and device

A connection device and connection method technology, which is applied in welding equipment, metal processing equipment, metal material coating technology, etc., can solve the problem of large deformation of magnesium-aluminum alloy joints, reduction of magnesium-aluminum alloy connection strength, unfavorable aluminum-magnesium alloy connection, etc. problem, achieve the effect of reducing heat loss, improving connection strength, and avoiding the generation of magnesium-aluminum intermetallic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Grinding and polishing the end faces of a magnesium alloy rod (AZ31B) and an aluminum alloy rod (7075) with a diameter of 10 mm and a length of 30 mm;

[0046] Among them, the grinding fingers of magnesium and aluminum alloys: use 400 # Sandpaper, 600 # Sandpaper, 800 # Sandpaper, 1200 # Sandpaper, 1500 # Grind the surface of the magnesium-aluminum alloy with sandpaper until it is bright, then put the bright magnesium alloy in alcohol to ultrasonically clean it for 15-20 minutes, take it out and blow it dry with a hair dryer;

[0047] The polishing of magnesium-aluminum alloy refers to: polish the polished sample with diamond polishing agent with particle size of W2.5, W1.5 and W0.5 in turn, polish the polished sample to a mirror effect, and then clean it with alcohol After drying, finally sealed in the sample bag.

[0048] (2) Then use magnetron sputtering equipment to carry out sputter coating on the polished magnesium and aluminum alloy rod end faces, so tha...

Embodiment 2

[0052] (1) The end faces of a magnesium alloy rod (AZ31B) with a diameter of 20 mm and a length of 30 mm and an aluminum alloy (7075) with a length of 30 mm, a width of 20 mm and a height of 20 mm were ground and polished according to the method in Example 1.

[0053] (2) Then use magnetron sputtering equipment to carry out sputter coating on the polished magnesium and aluminum alloy rod end faces, so that a layer of amorphous film is formed on the end faces of magnesium and aluminum alloy rods, and the coating target is zirconium-based amorphous LM1B, The thickness of the amorphous film is 1 μm.

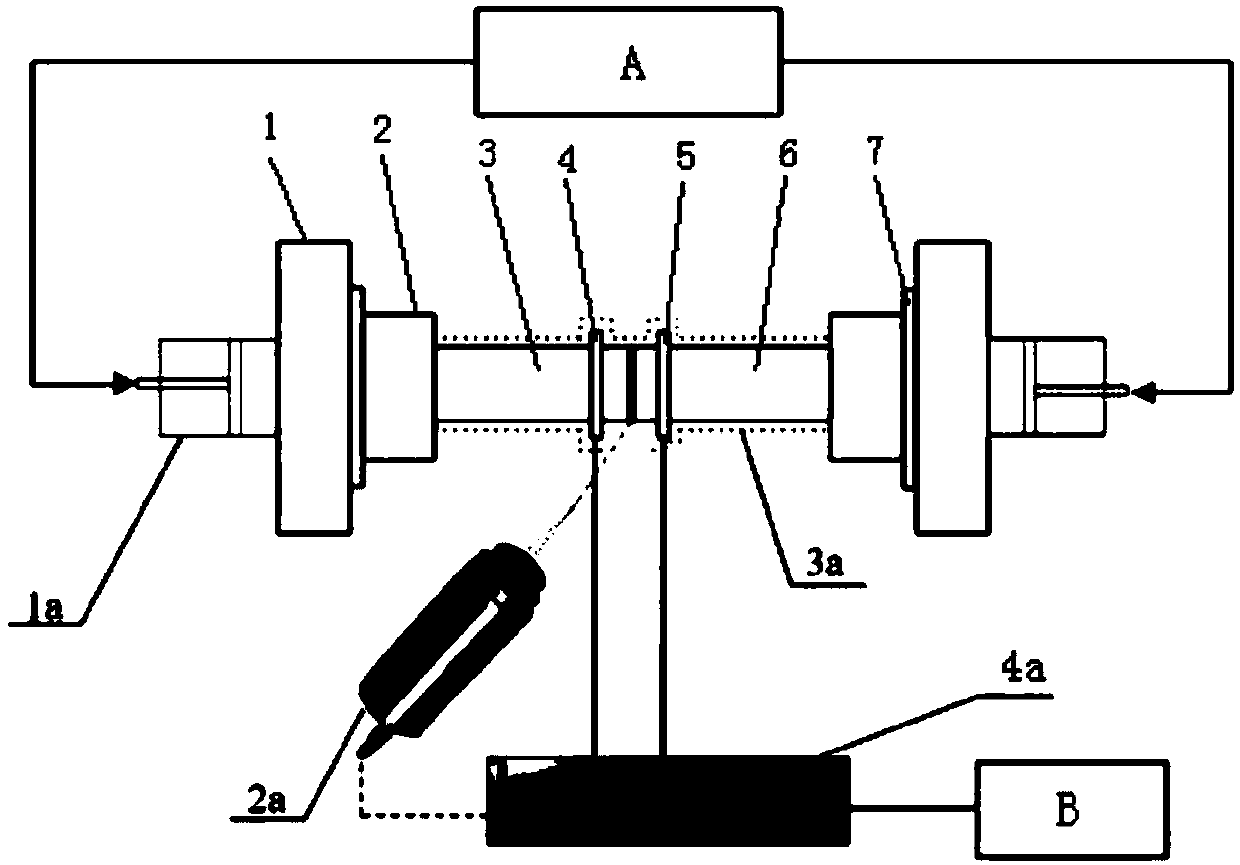

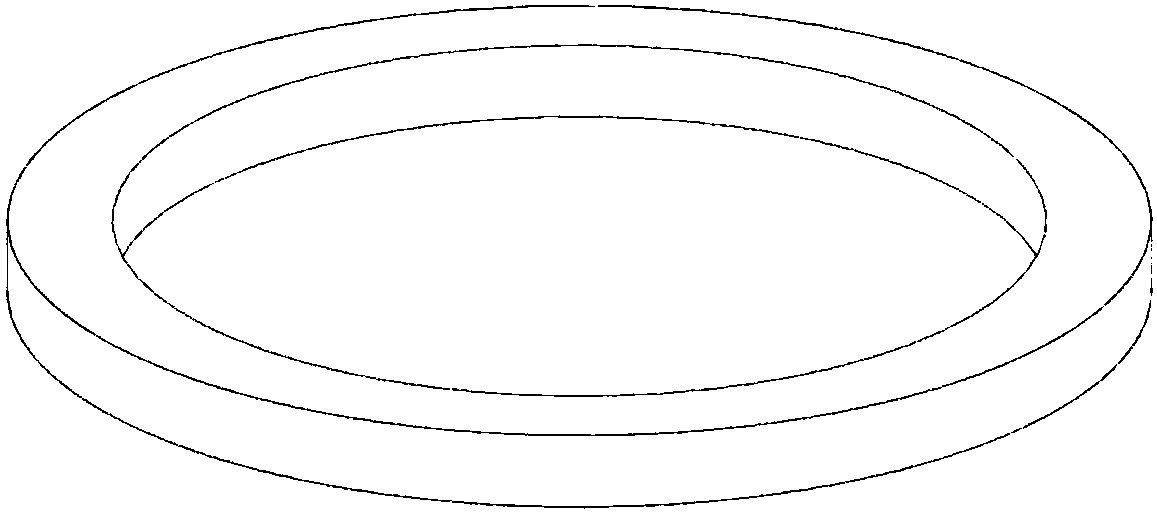

[0054] (3) Fix the magnesium and aluminum alloy rods after sputtering coating on the fixture, place the ring electrode in the area where the aluminum alloy and magnesium alloy are to be heated, and wrap two layers of 5mm thick heat insulation cotton on the magnesium alloy and aluminum alloy , The surface of the ring-shaped heating electrode, fix the infrared thermometer so that the ...

Embodiment 3

[0057] (1) The end faces of magnesium alloy rods (AZ31B) and aluminum alloy rods (7075) with a diameter of 20 mm and a length of 30 mm were ground and polished according to the method in Example 1.

[0058] (2) Then use magnetron sputtering equipment to carry out sputter coating on the polished magnesium and aluminum alloy rod end faces, so that a layer of amorphous film is formed on the end faces of magnesium and aluminum alloy rods, and the coating target is zirconium-based amorphous LM1B, The thickness of the amorphous film is 2 μm.

[0059] (3) Fix the magnesium and aluminum alloy rods after sputtering coating on the fixture, place the ring electrode in the area where the aluminum alloy and magnesium alloy are to be heated, and wrap two layers of 5mm thick heat insulation cotton on the magnesium alloy and aluminum alloy , The surface of the ring-shaped heating electrode, fix the infrared thermometer so that the laser hits the joint of the magnesium-aluminum alloy, turn on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com