Method for preparing crystalline silicon by using diamond wire cutting wastes of crystalline silicon

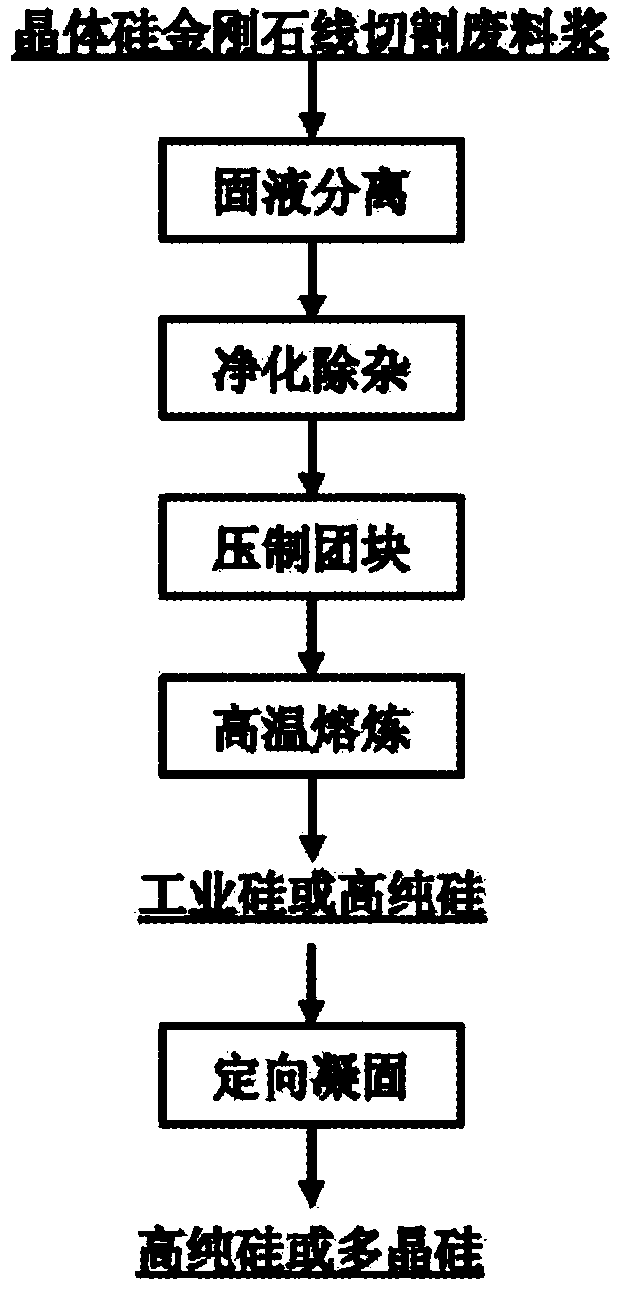

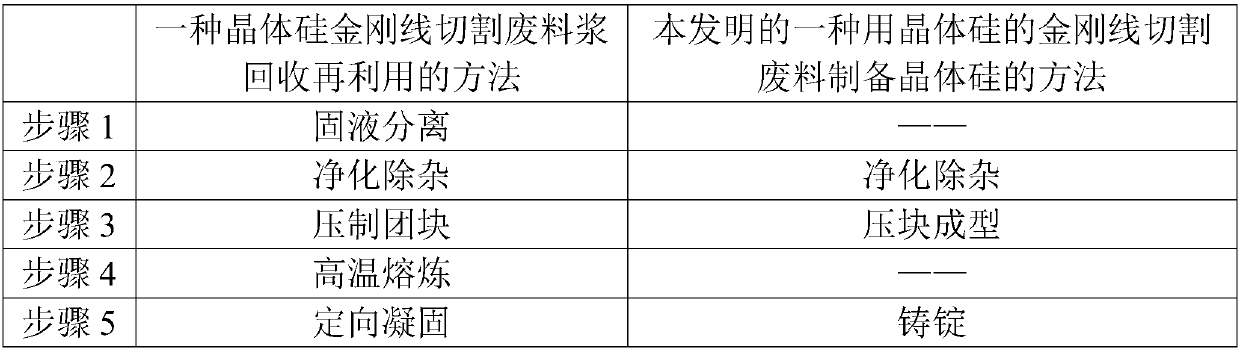

A diamond wire cutting and crystalline silicon technology, applied in crystal growth, polycrystalline material growth, chemical instruments and methods, etc., can solve the problem of less research on the utilization of diamond wire cutting waste, and achieve easy industrial production, short process, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

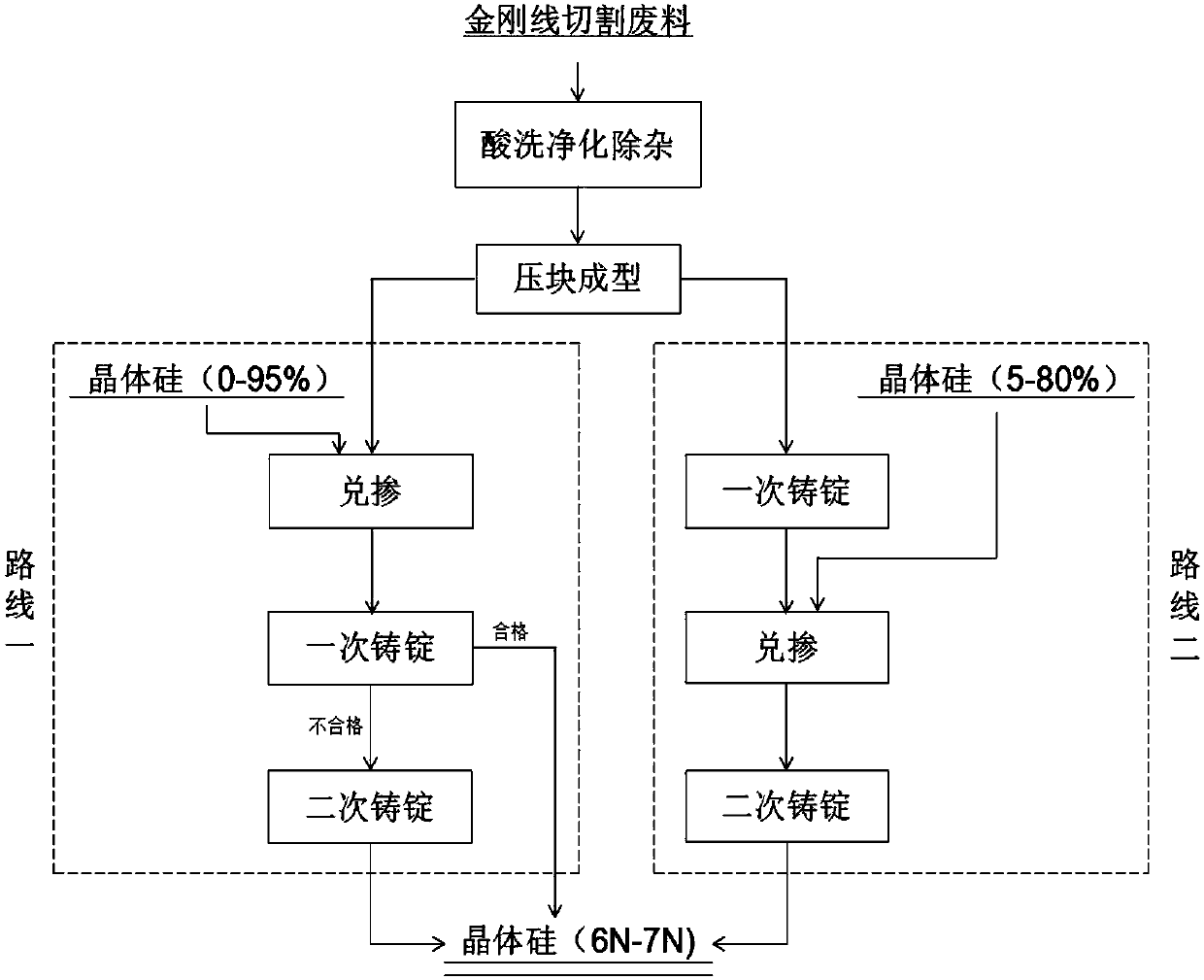

[0032] A method for preparing crystalline silicon from diamond wire cutting waste of crystalline silicon is carried out in the following steps:

[0033] (1) The cutting waste is pickled to remove impurities, and the slurry obtained from the pickling is filtered, washed with water, and dried to obtain purified diamond wire cutting waste powder of crystalline silicon. The acid used for pickling and impurity removal is hydrochloric acid (HCl), and the pickling conditions are: acid concentration 5%, pickling temperature 90°C, pickling time 60min, solid-liquid ratio 1:10. During the pickling process, mechanical stirring is used to improve the pickling effect.

[0034] (2) Under the condition of not adding water and binder, the powder after pickling and purification is pressed into blocks by cold isostatic pressing. The pressure used for forming is 300MP, and the holding time is 200s. After forming of blocks.

[0035] (3) The above block is directly cast into an ingot once, and th...

Embodiment 2

[0038] A method for preparing crystalline silicon from diamond wire cutting waste of crystalline silicon is carried out in the following steps:

[0039] (1) The cutting waste is pickled to remove impurities, and the slurry obtained from the pickling is filtered, washed with water, and dried to obtain purified diamond wire cutting waste powder of crystalline silicon. The acid used for pickling and impurity removal is sulfuric acid (H 2 SO 4 ), the pickling conditions are: acid concentration 40%, pickling temperature 20°C, pickling time 30min, solid-liquid ratio 1:5. During the pickling process, mechanical stirring is used to improve the pickling effect.

[0040] (2) Mix 20% of water and 5% of binder into the powder after pickling and purification, mix evenly in the mixer, and then use cold isostatic pressing to form the material The briquette is formed under the conditions, the pressure used for forming is 200MP, and the holding time is 5s, and the formed block is obtained. ...

Embodiment 3

[0044] A method for preparing crystalline silicon from diamond wire cutting waste of crystalline silicon is carried out in the following steps:

[0045] (1) The cutting waste is pickled to remove impurities, and the slurry obtained from the pickling is filtered, washed with water, and dried to obtain purified diamond wire cutting waste powder of crystalline silicon. The acid used for pickling and impurity removal is hydrofluoric acid (HF), and the pickling conditions are: acid concentration 25%, pickling temperature 50°C, pickling time 300min, solid-to-liquid ratio 1:2. During the pickling process, mechanical stirring is used to improve the pickling effect.

[0046] (2) Mix 40% of water and 10% of binder into the powder after pickling and purification, mix evenly in the mixer, and then press the material under the conditions by molding Block forming, the pressure used for forming is 5MP, and the holding time is 300s to obtain the formed block.

[0047] (3) Blending the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com