Catalyst for negative electrode material of hydrogen-air fuel battery and preparation method thereof

A fuel cell cathode and catalyst technology, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high price, poor catalyst stability, and no reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Another aspect of the present invention provides a method for preparing a group VIII polyatomic dispersed catalyst. In one embodiment, the preparation method of the present invention comprises the following steps:

[0036] Step 1, the methanol solution of the first VIII group atom compound and the methanol solution of the Zn compound (wherein the molar ratio of the first VIII group atom compound and the Zn compound is 1 / 1 to 1 / 10) is added to the organic ligand methanol solution, or only the methanol solution of the Zn compound is added to the methanol solution of the organic ligand, dissolved while sonicating, and then the mixed solution is stirred overnight;

[0037] In step 2, the mixed solution obtained in step 1 is centrifuged and washed with methanol for 3-5 times, and dried overnight in an oven at 60°C-90°C to obtain solid powders containing the first group VIII atoms and Zn atoms and solid powders containing only Zn atoms, respectively. Atomic solid powder;

...

preparation Embodiment 1

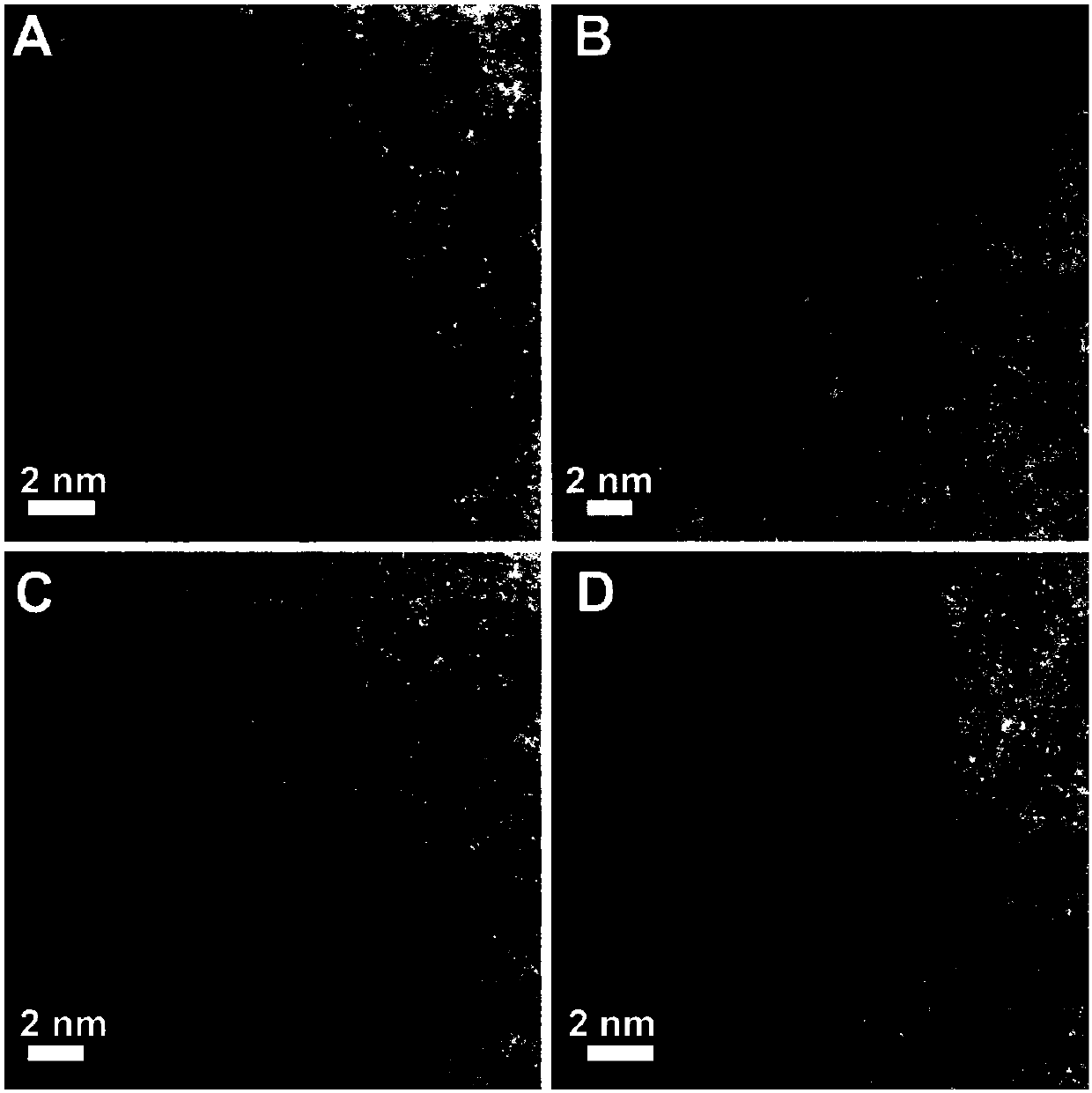

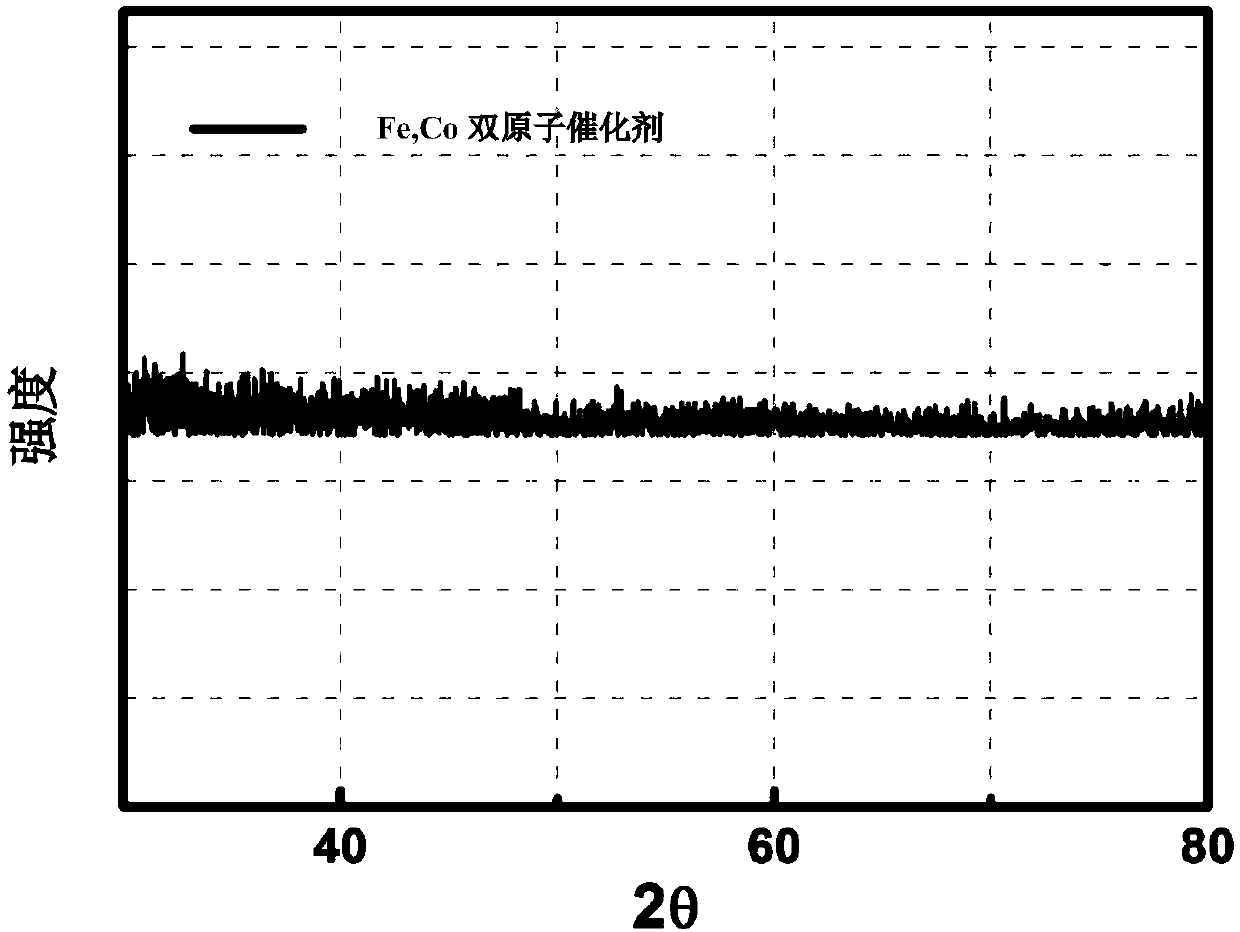

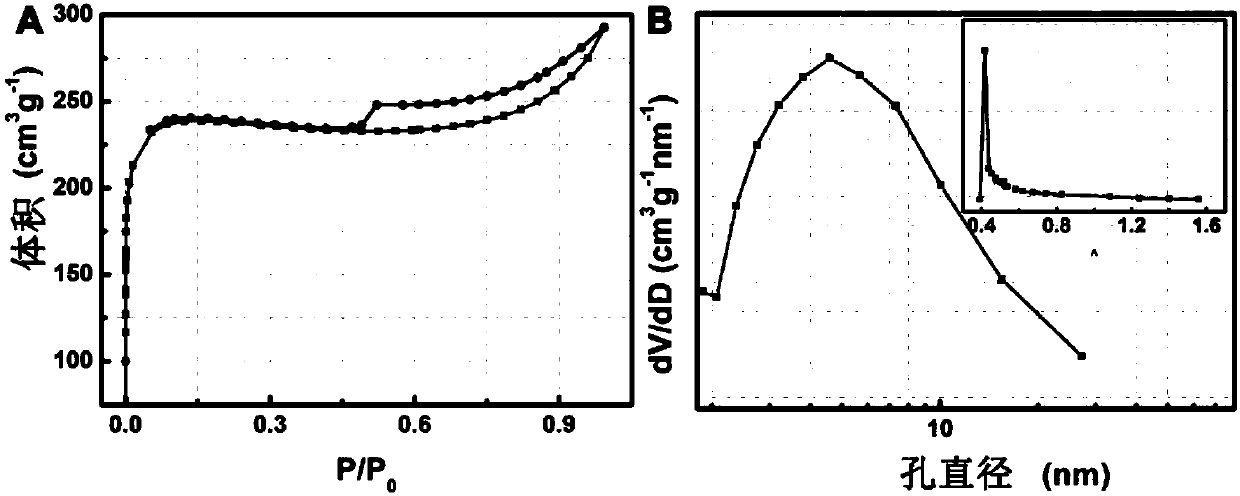

[0059] Preparation of Fe, Co diatomically dispersed catalyst:

[0060] (1) configure 0.125mol / L zinc nitrate hexahydrate methanol solution and 0.125mol / L cobalt nitrate hexahydrate methanol solution, 0.5mol / L dimethylimidazole methanol solution; then 15 milliliters of 0.125mol / L hexahydrate Zinc nitrate methanol solution and 15 milliliters of 0.125mol / L cobalt nitrate hexahydrate methanol solution were mixed and then added to 30 milliliters of dimethylimidazole methanol solution, dissolved while ultrasonic, and then the mixed solution was stirred overnight;

[0061] (2) Wash the obtained mixed solution by centrifugation with methanol for 3-5 times, and dry in an oven at 70°C overnight to obtain a solid powder;

[0062] (3) Disperse the metal-organic framework obtained above in n-hexane, then add 50ul of ferric chloride aqueous solution with a concentration of 50mg / ml, stir for 1-3h, then wash and dry;

[0063](4) Put the obtained solid powder into a porcelain boat, then put t...

preparation Embodiment 2

[0065] Preparation of Catalysts with Diatomic Dispersion of Fe and Co in Different Atomic Ratio

[0066] (1) configure 0.125mol / L zinc nitrate hexahydrate methanol solution and 0.125mol / L cobalt nitrate hexahydrate methanol solution, 0.5mol / L dimethylimidazole methanol solution; then 15 milliliters of 0.125mol / L hexahydrate Zinc nitrate methanol solution and 15 milliliters of 0.125mol / L cobalt nitrate hexahydrate methanol solution were mixed and then added to 30 milliliters of dimethylimidazole methanol solution, dissolved while ultrasonic, and then the mixed solution was stirred overnight;

[0067] (2) Wash the obtained mixed solution by centrifugation with methanol for 3-5 times, and dry in an oven at 70°C overnight to obtain a solid powder;

[0068] (3) Disperse the metal-organic framework obtained above in n-hexane, then add 50 ul of an aqueous solution of ferric chloride with a concentration of 10 mg / ml or 50 ul of an aqueous solution of ferric chloride with a concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com