Medical antibacterial coating layer and preparation method thereof

A coating and performance technology, applied in the field of medical antibacterial coating materials and their preparation, can solve the problems of increasing the preparation cost, wasting scarce resources, etc., and achieves the effect of saving resources, efficient antibacterial effect, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

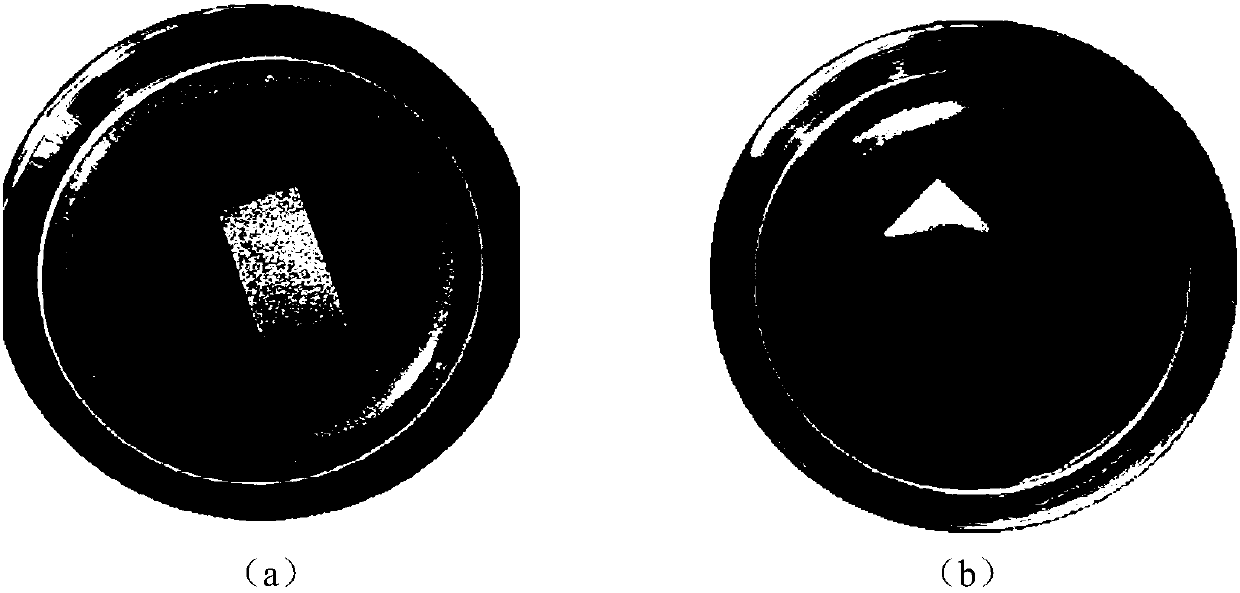

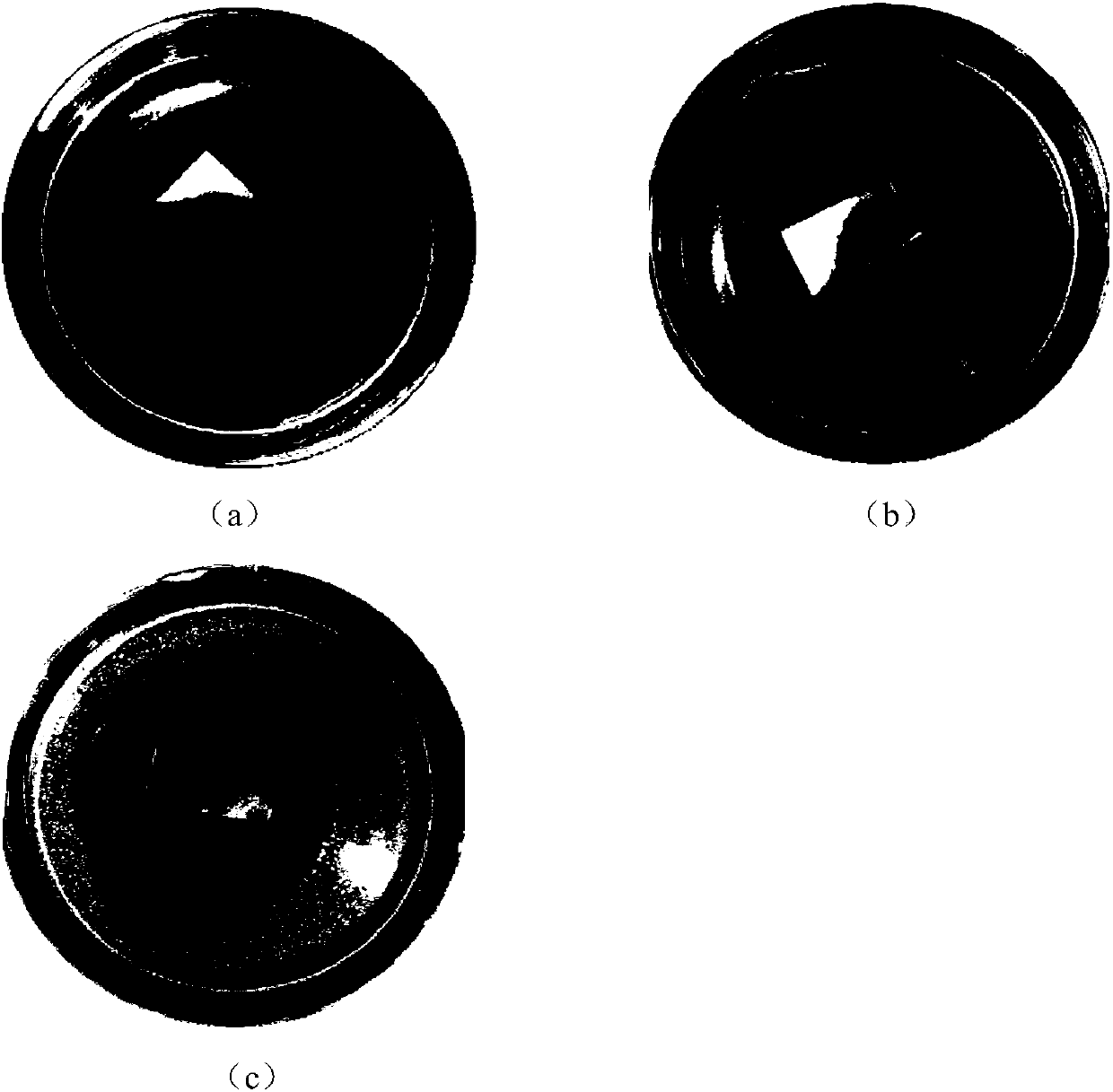

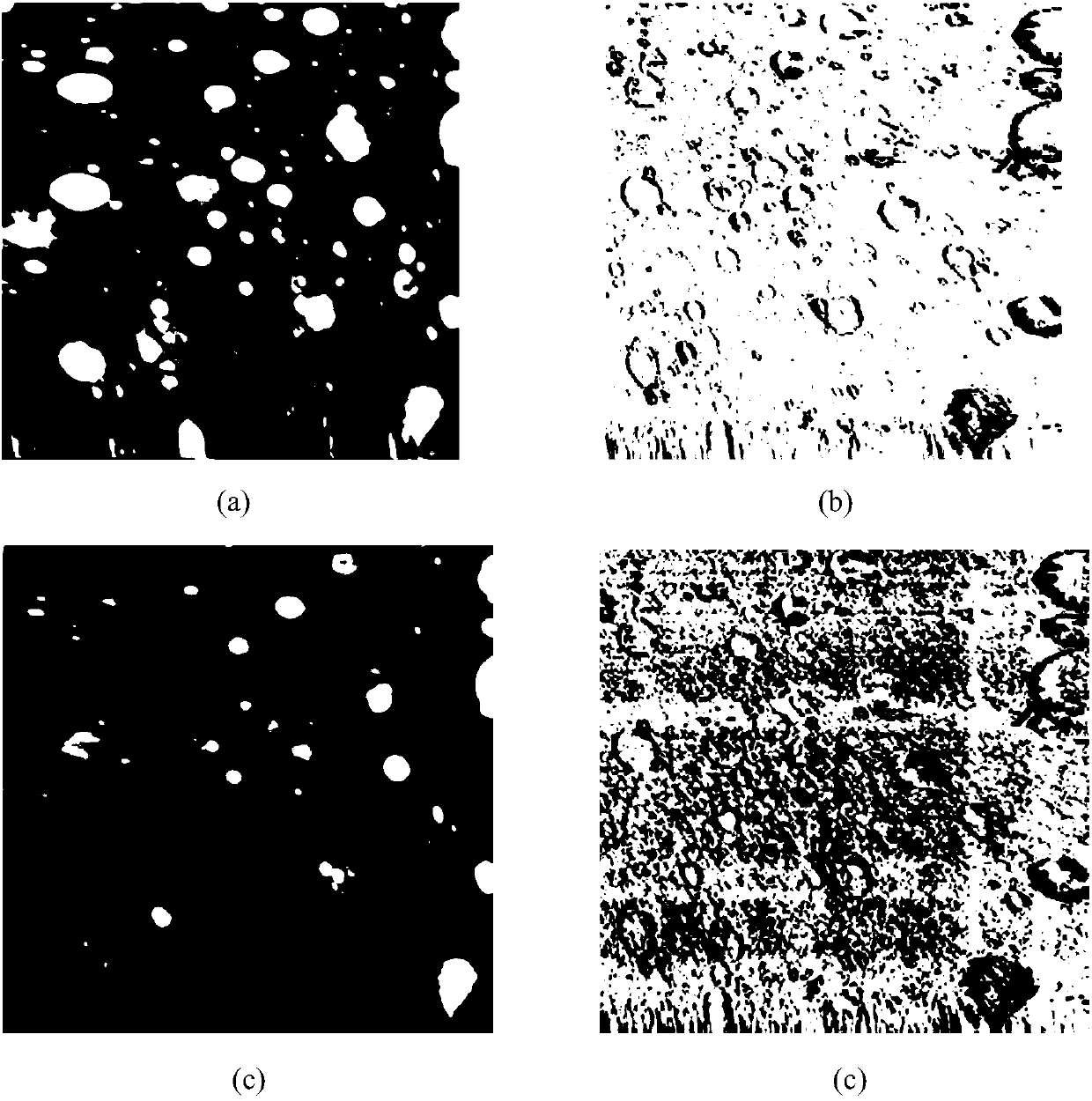

Image

Examples

Embodiment 1

[0024] Present embodiment is a kind of preparation method of HA coating, comprises the following steps:

[0025] The first step: chemically clean the surface of quartz, aluminum alloy, and single crystal silicon wafers to remove grease and other pollutants on the surface. Washing with water; ultrasonic cleaning in acetone solution, ethanol solution and deionized water to improve the surface activity of the substrate, thereby enhancing the bonding force between the film and the substrate material; after cleaning, place the substrate in an oven to dry and store.

[0026] Step 2: Take 7.5g of HA powder and press it into a target with a diameter of 30mm and a target thickness of 5mm with a tablet press;

[0027] Step 3: Place the above target in the target position of the pulsed laser deposition vacuum chamber, and place the above substrate in the substrate position of the vacuum chamber;

[0028] Step 4: Start the pulse laser instrument and adjust the pulse laser intensity to 50...

Embodiment 2

[0032] Present embodiment is a kind of preparation method of HA-silver nitrate nanocomposite coating, comprises the following steps:

[0033] The first step: chemically clean the surface of quartz, aluminum alloy, and single crystal silicon wafers to remove grease and other pollutants on the surface. Washing with water; ultrasonic cleaning in acetone solution, ethanol solution and deionized water to improve the surface activity of the substrate, thereby enhancing the bonding force between the film and the substrate material; after cleaning, place the substrate in an oven to dry and store.

[0034] Step 2: Take 6g of HA and 1.5g of silver nitrate powder and grind them mechanically, mix them evenly according to the mass ratio of 4:1, and press them into a target with a diameter of 30mm and a target thickness of 5mm with a tablet press;

[0035] Step 3: Place the above target in the target position of the pulsed laser deposition vacuum chamber, and place the above substrate in th...

Embodiment 3

[0040] Present embodiment is a kind of preparation method of HA and norfloxacin active antibacterial coating, comprises the steps:

[0041] The first step: chemically clean the surface of quartz, aluminum alloy, and single crystal silicon wafers to remove grease and other pollutants on the surface. Washing with water; ultrasonic cleaning in acetone solution, ethanol solution and deionized water to improve the surface activity of the substrate, thereby enhancing the bonding force between the film and the substrate material; after cleaning, place the substrate in an oven to dry and store.

[0042] The second step: take 6g HA and 1.5g norfloxacin according to the mass ratio of 4:1, mechanically grind and mix them evenly, and press them into a target with a diameter of 30mm and a target thickness of 5mm with a tablet press;

[0043] Step 3: Place the above target in the target position of the pulsed laser deposition vacuum chamber, and place the above substrate in the substrate po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com