Liquid-state electrolyte-based secondary lithium battery without negative electrode

A secondary lithium battery and liquid electrolyte technology, applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of low energy density, reduce the contact area, simplify the technology, and inhibit the generation of dendrites Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

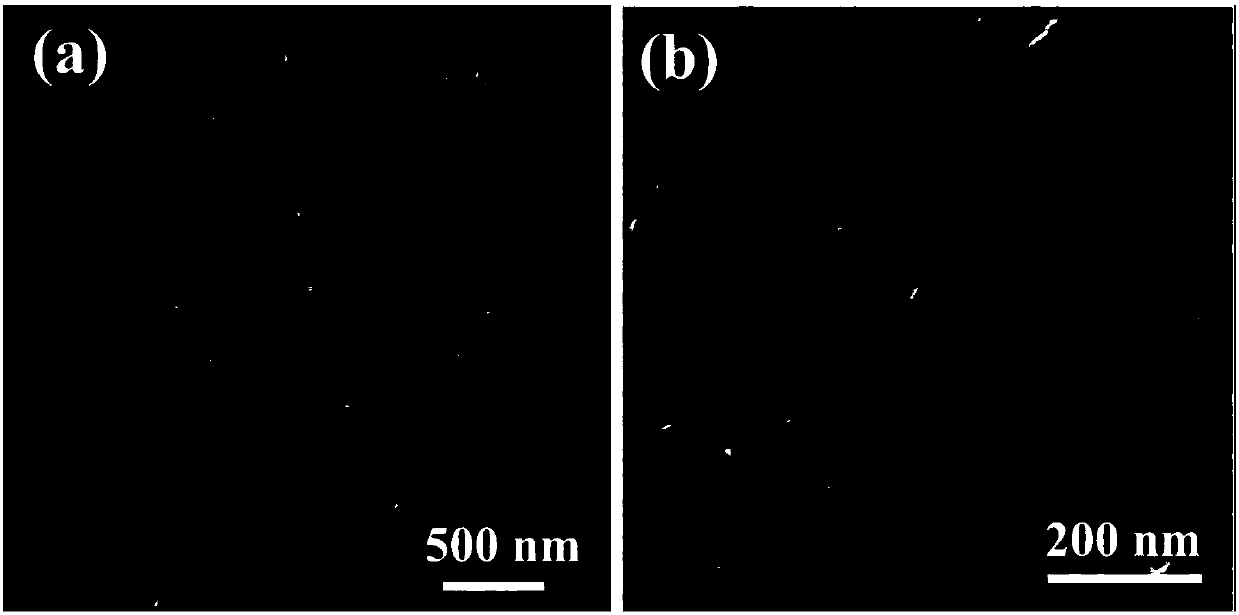

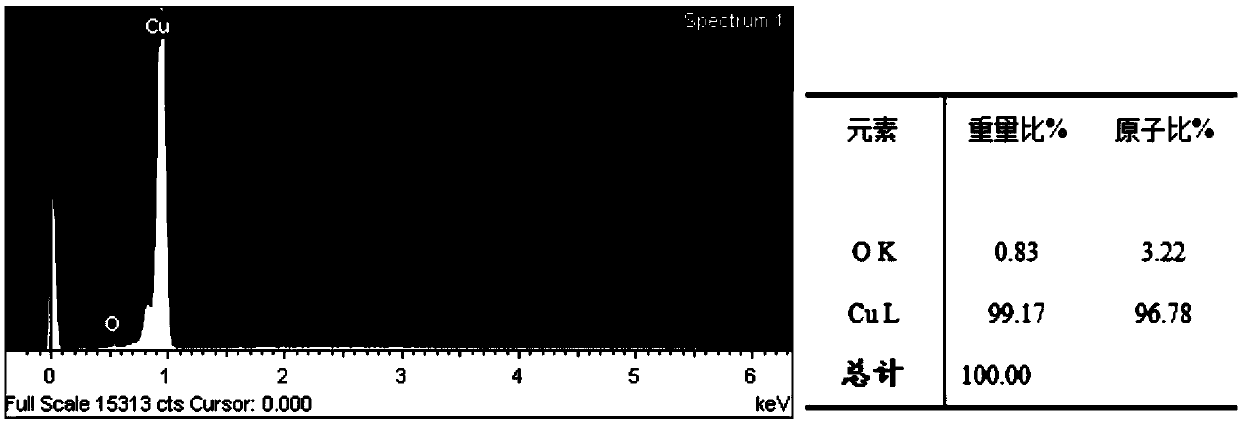

[0053] Using 10 μm copper foil as the negative current collector, the copper foil was immersed in 1% HNO 3 The aqueous solution was ultrasonically cleaned for 5 min to remove the oxide layer. The acid-treated copper foil was cleaned with ethanol and allowed to dry at room temperature. Subsequently, Ar ion beam etching was used to further remove the residual oxide layer on the surface. The treated copper foil was quickly transferred to a glove box, and the copper foil was cut into discs with a diameter of 15 mm by a punching machine in the glove box. The gold-sprayed sample was directly stored in the glove box, ready for the next electrochemical performance test (this material is counted as A1).

Embodiment 2

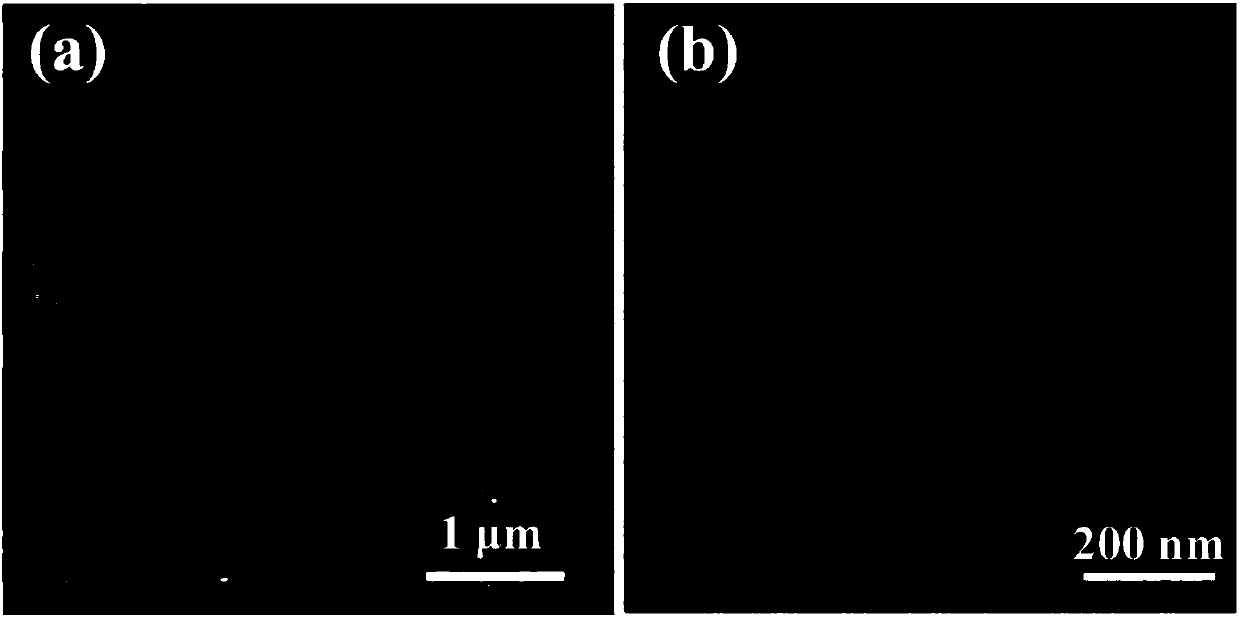

[0055] Using 10 μm copper foil as the negative current collector, the copper foil was immersed in 1% HNO 3 The aqueous solution was ultrasonically cleaned for 5 min to remove the oxide layer. The acid-treated copper foil was cleaned with ethanol and allowed to dry at room temperature. Subsequently, Ar ion beam etching was used to further remove the residual oxide layer on the surface. The treated copper foil was quickly transferred to a glove box, and the current collector was cut into discs with a diameter of 15 mm by a punching machine in the glove box. Gold was sprayed on the sample using a small magnetron sputtering device placed in a glove box, and deposited at a current of 1 mA for 60 s.

[0056] The sample after gold spraying was directly stored in the glove box, and was prepared for the next step of electrochemical performance test (this material was counted as A2).

Embodiment 3

[0058] Using 10 μm copper foil as the negative current collector, the copper foil was immersed in 1% HNO 3 The aqueous solution was ultrasonically cleaned for 5 min to remove the oxide layer. Clean the acid-treated copper foil with deionized water and ethanol, and dry it at room temperature after cleaning. Subsequently, Ar ion beam etching was used to further remove the residual oxide layer on the surface. The treated copper foil was quickly transferred to a glove box, and the current collector was cut into discs with a diameter of 15 mm by a punching machine in the glove box. A small magnetron sputtering device placed in a glove box was used to spray gold on the sample, and deposited at a current of 1 mA for 120 s. The sample after spraying gold is directly stored in the glove box, and is ready for the next step of electrochemical performance test (this material is counted as A3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com