Preparation method of modifying composite nanofiltration membrane by building pure COFs interlayer

A composite nanofiltration membrane and intermediate layer technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of few interfacial polymerization processes, inability to fully infiltrate amine monomers, and low flux. Achieve excellent separation performance, achieve precise regulation, and high water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the preparation of pure COFs intermediate layer modified composite nanofiltration membrane, the steps are as follows:

[0021] Step 1. Preparation of TpPa-1 by Schiff base condensation: 0.3 mmol of 1,3,5-triformylphloroglucinol, 0.45 mmol of p-phenylenediamine, and 3 mL of 1,3 with a volume ratio of 1:1 , 5-trimethylbenzene / dioxane mixed solution, 0.5 mL of acetic acid aqueous solution with a concentration of 3 mol / L were placed in a heat-resistant flask, ultrasonicated for 2 min to obtain a mixed-phase suspension; and freeze-vacuum-thawed 3 times Cycle operation to room temperature. The freezing process is to place the flask in 77K liquid nitrogen to quickly freeze; after sealing, heat at 120 °C for three days to form a dark red precipitate and then collect by centrifugation; sequentially use acetone, tetrahydrofuran and dichloromethane to wash the precipitate, After collection, solvent exchange was performed in acetone, and then vacuum dried at 180 °C fo...

Embodiment 2

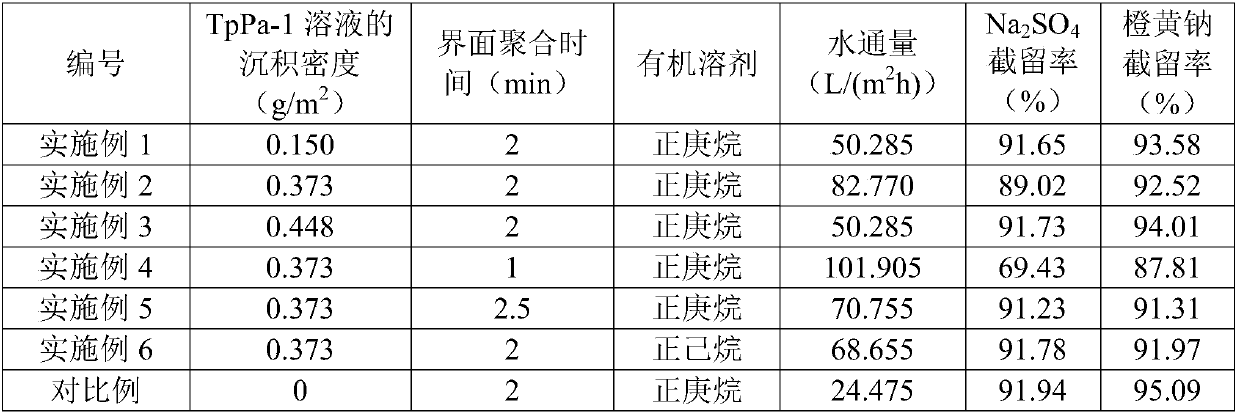

[0025] Example 2. Preparation of pure COFs interlayer modified composite nanofiltration membrane. The preparation process is basically the same as that in Example 1, except that: in the construction of the TpPa-1 interlayer in step 2, the deposition density of TpPa-1 was changed from 0.150 g / m 2 Change to 0.373g / m 2 , and finally obtained the pure COFs interlayer modified composite nanofiltration membrane, denoted as composite nanofiltration membrane 2.

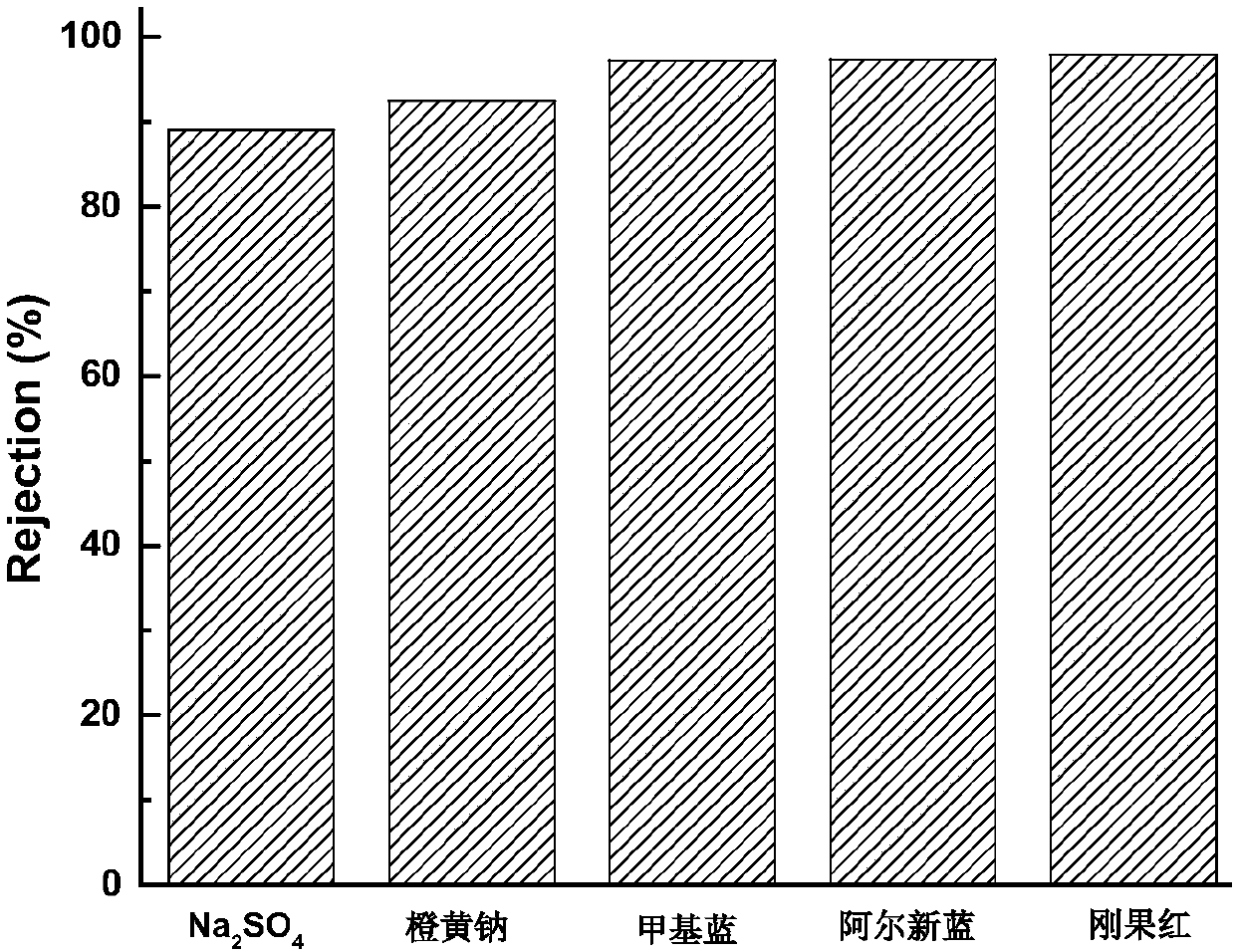

[0026] The water flux of the composite nanofiltration membrane 2 prepared in Example 2 under the operating pressure of 0.2MPa is 82.770L / (m 2 h), for Na 2 SO 4 (mass fraction 0.1%), the retention rate was 89.02%, and the retention rate for the aqueous solution of orange yellow sodium (mass fraction 0.01%) was 92.52%. figure 1 Modified composite nanofiltration membrane 2 for pure COFs intermediate layer against Na 2 SO 4 (mass fraction of 0.1%), orange yellow sodium, Congo red, methyl blue and alcian blue (mass fraction ...

Embodiment 3

[0027] Example 3. Preparation of pure COFs interlayer modified composite nanofiltration membrane. The preparation process is basically the same as that in Example 1, except that in the construction of the TpPa-1 interlayer in step 2, the deposition density of TpPa-1 was changed from 0.150g to 0.150g. / m 2 Change to 0.448g / m 2 , and finally obtained the pure COFs interlayer modified composite nanofiltration membrane, which is denoted as composite nanofiltration membrane.

[0028] The water flux of the composite nanofiltration membrane 3 prepared in Example 3 under the operating pressure of 0.2MPa is 50.285L / (m 2 h), for Na 2 SO 4 (mass fraction 0.1%), the retention rate was 91.73%, and the retention rate for the aqueous solution of orange yellow sodium (mass fraction 0.01%) was 94.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com