Iridium monatomic catalyst used for direct formic acid fuel cell, and preparation method of catalyst

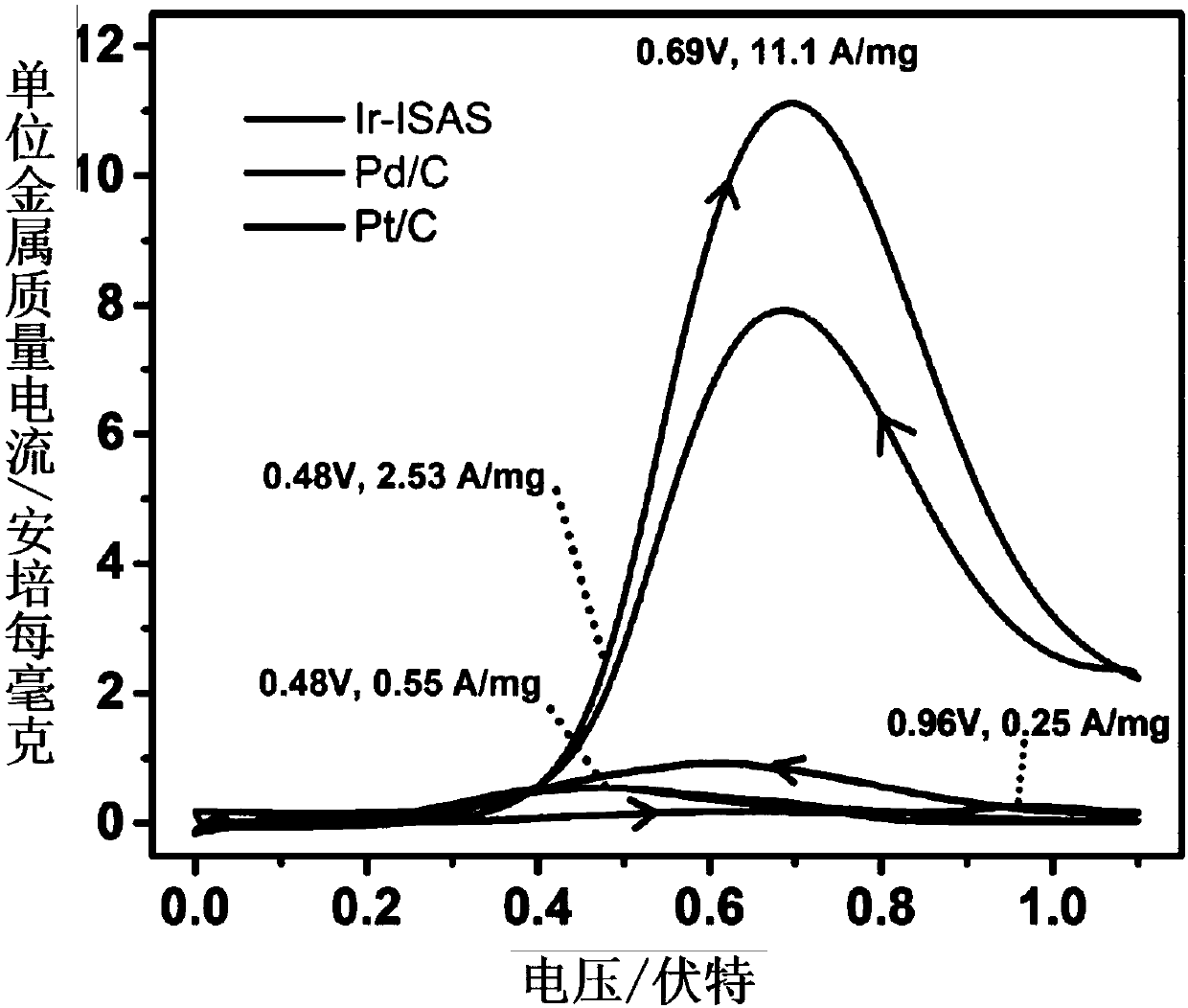

A formic acid fuel cell and catalyst technology, which is applied to fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of easy deactivation of catalysts, high prices, gaps, etc., and achieves a simple and easy preparation method and high atomic utilization rate. , the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A kind of preparation method for the iridium single-atom catalyst of direct formic acid fuel cell provided by the invention, it specifically comprises the steps:

[0020] 1) Add the iridium metal compound methanol solution and the zinc metal compound methanol solution to the imidazole organic ligand methanol solution, react at room temperature for 12 to 36 hours to obtain a suspension; then wash the suspension with methanol and dry, A solid powder was obtained. The molar concentration of the iridium metal compound methanol solution is 0.024~0.027mol / L, the molar concentration of the zinc metal compound methanol solution is 0.24~0.27mol / L, and the molar concentration of the imidazole organic ligand methanol solution is 0.53~ 1.42mol / L; wherein, the volume ratio among the iridium metal compound methanol solution, the zinc metal compound methanol solution, and the imidazole organic ligand methanol solution is 1:1:0.5~2;

Embodiment 1

[0024] (1) configure 0.024mol / L iridium acetylacetonate methanol solution and 0.240mol / L zinc nitrate methanol solution, 1.42mol / L 2-methylimidazole methanol solution; then iridium acetylacetonate methanol solution, zinc nitrate methanol solution and The 2-methylimidazole methanol solution was mixed evenly at a volume ratio of 1:1:1.5, and then the mixed solution was stirred at room temperature for 24 hours;

[0025] (2) The obtained suspension is washed with methanol centrifuge and dried to obtain a solid powder;

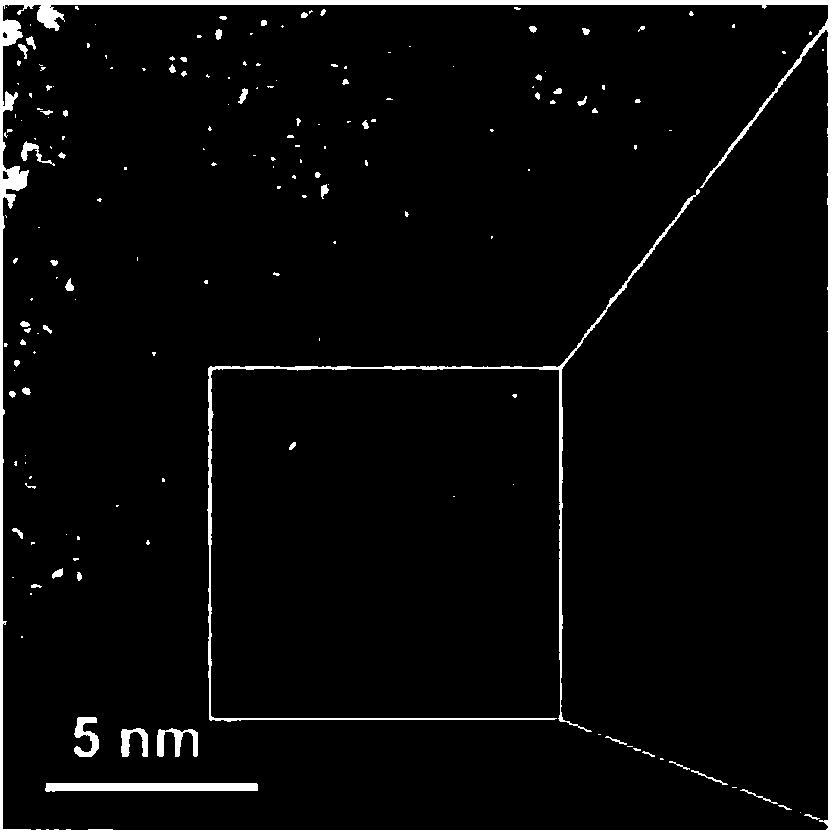

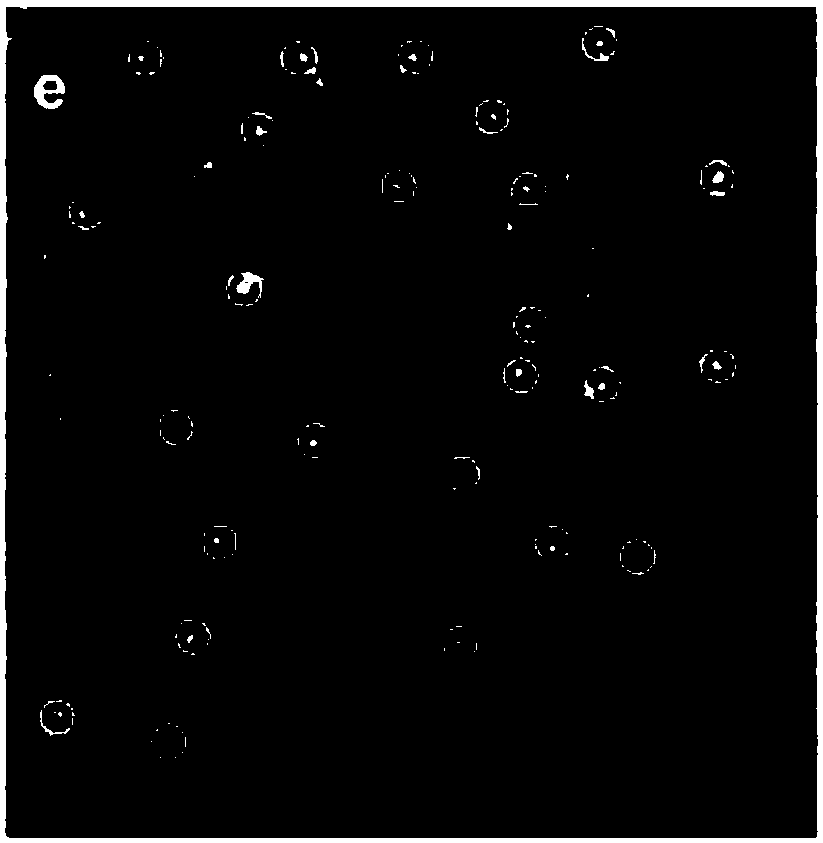

[0026] (3) Put the obtained solid powder into a porcelain boat, then put the porcelain boat into a tube furnace, seal and pass in an inert gas, heat up to 900°C under an inert atmosphere, calcinate for 3 hours, then cool down to room temperature naturally, and take out the black solid The material is the desired single-atom catalyst, as shown in Figure 1, it is observed under the electron microscope that the iridium single atoms are uniformly dispersed on the nitro...

Embodiment 2

[0028] (1) configure 0.024mol / L iridium acetylacetonate methanol solution and 0.270mol / L zinc nitrate methanol solution, 1.42mol / L 2-methylimidazole methanol solution; then iridium acetylacetonate methanol solution, zinc nitrate methanol solution and The 2-methylimidazole methanol solution was mixed evenly at a volume ratio of 1:1:1.5, and then the mixed solution was stirred at room temperature for 12 hours;

[0029] (2) The obtained suspension is washed with methanol centrifuge and dried to obtain a solid powder;

[0030] (3) Put the obtained solid powder into a porcelain boat, then put the porcelain boat into a tube furnace, seal and pass in an inert gas, heat up to 800°C under an inert atmosphere, calcinate for 4 hours, then cool down to room temperature naturally, and take out the black solid The material is the desired single-atom catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com