A carbon-based bimetallic composite material, its preparation and application

A composite material and bimetallic technology, applied in the field of new carbon-based bimetallic composite double-shell hollow structure electrocatalysts, can solve the problems of complex catalyst preparation methods and difficult control of preparation process conditions, and achieve good application prospects and economic value. The effect of mild conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

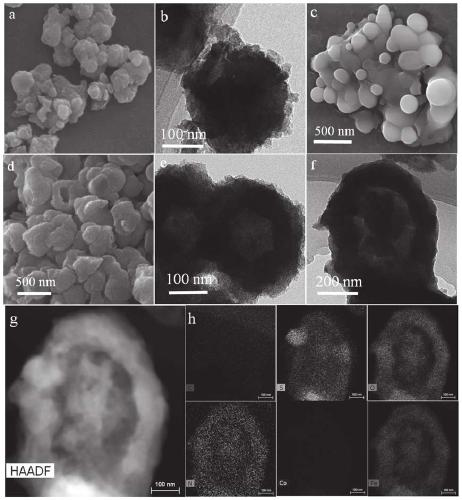

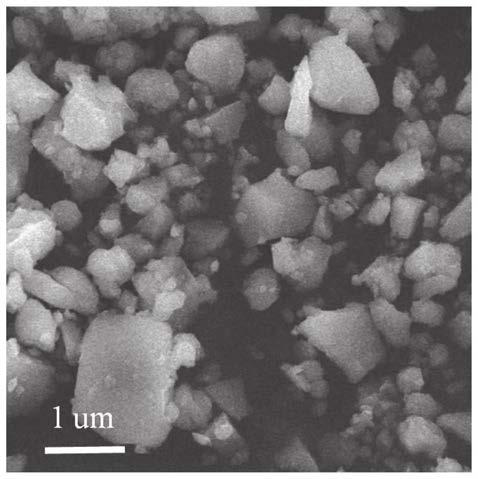

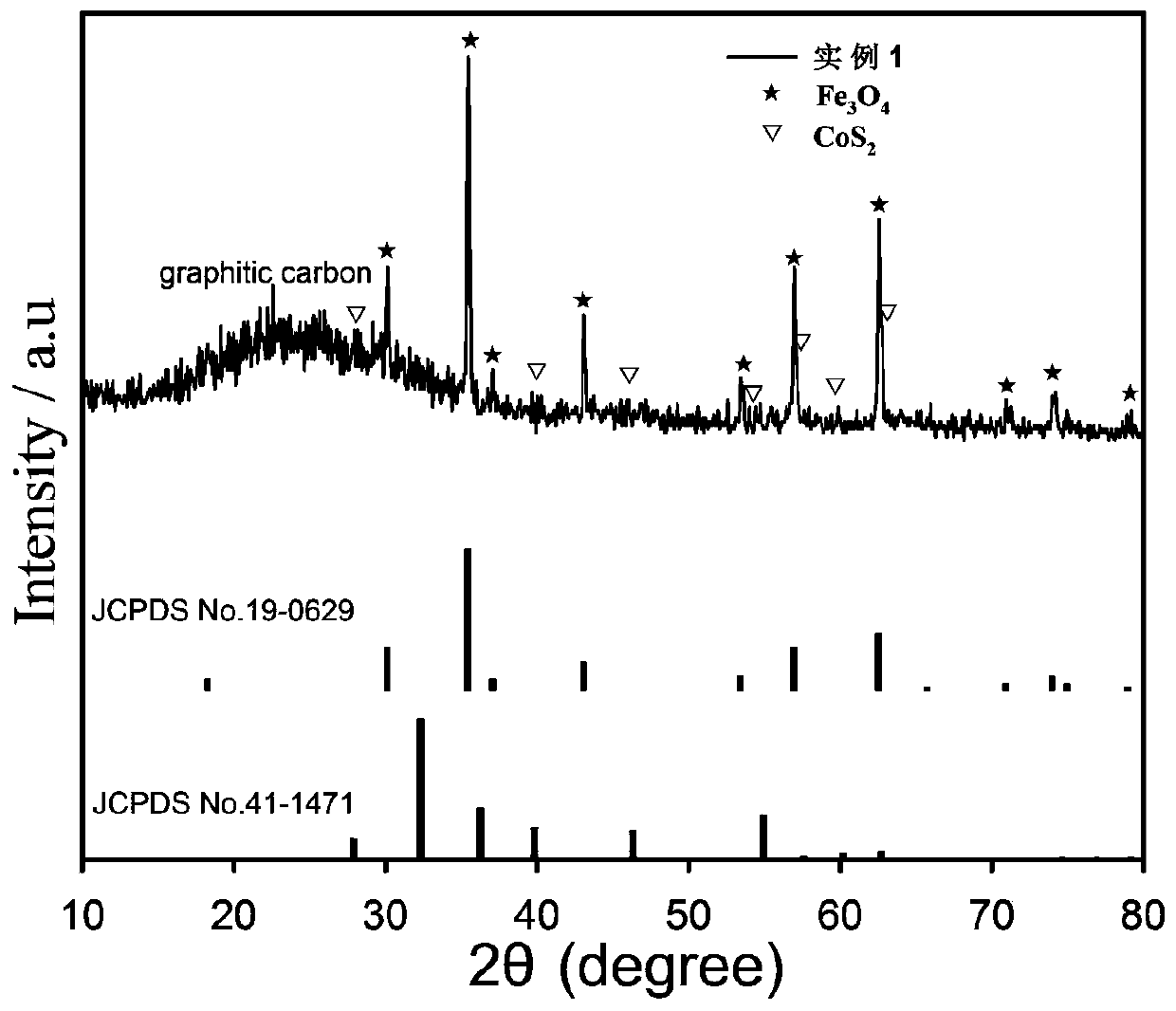

[0070] Take 3 mol of cobalt salt (cobalt nitrate), 8 mol of dimethylimidazole, and 1 mol of iron salt (ferric chloride), and dissolve them in 40 mL of methanol respectively, and ultrasonicate for 10 min to form a uniform solution, and then add the methanol solution of cobalt salt at a rate of 5 mL / min. Add the methanol solution of dimethylimidazole at the acceleration rate, continue to sonicate for 10min, then add the methanol solution of iron salt to the above solution at a dropping rate of 5mL / min, continue to sonicate for 30min, then transfer to the autoclave and heat to 120 ℃ for 4 hours, cooled to room temperature, washed and centrifuged three times alternately with water and absolute ethanol, and vacuum-dried at 60℃ for 10 hours to obtain hollow Co 3 / Fe 1 Bimetallic MOF (SEM and TEM drawings see figure 1 c and e); take 10g hollow Co 3 / Fe 1 The bimetallic MOF was ground evenly with 10g of sublimated sulfur, heat-treated in an argon atmosphere at a heating rate of 5°C...

Embodiment 2

[0073] Compared with Example 1, the only difference is that the molar ratio of metal cobalt salt to iron salt is 4:1; other materials and parameters are unchanged. A composite material with a structure and morphology similar to Example 1 was obtained. The oxygen evolution performance results are as follows: at a current density of 10mA / cm 2 The oxygen evolution potential is 0.63V; the TOF is 11.3s at an overpotential of 320mV -1 .

Embodiment 3

[0075] Compared with Example 1, the only difference is that the molar ratio of metal cobalt salt to iron salt is 2:1; other materials and parameters are unchanged. A composite material with a structure and morphology similar to Example 1 was obtained. The oxygen evolution performance results are as follows: at a current density of 10mA / cm 2 The oxygen evolution potential is 0.67V; the TOF is 8.6s at an overpotential of 320mV -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com