Preparation method of high-defect boron nitride supported atomic-scale dispersed metal catalyst

A technology of metal catalysts and boron nitride, which is applied in the field of synthesis of atomically dispersed metal catalysts, can solve the problems of not being simple enough, unable to realize wide application, high equipment requirements, etc., and achieve cheap raw materials, excellent ORR catalytic performance, and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

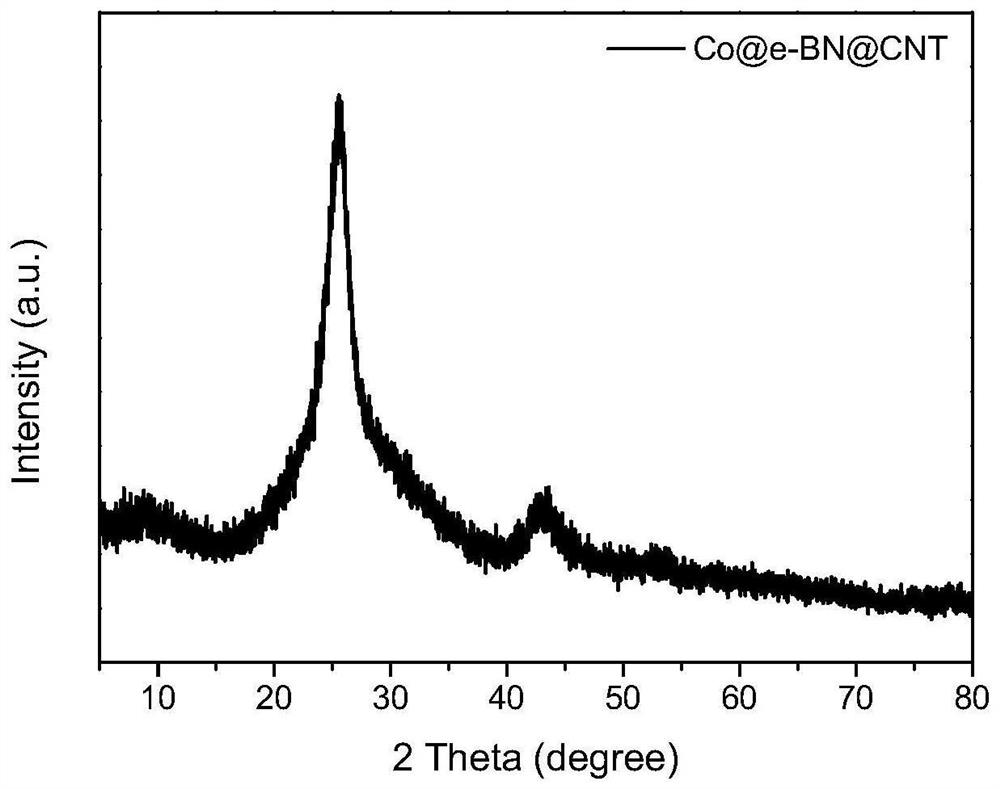

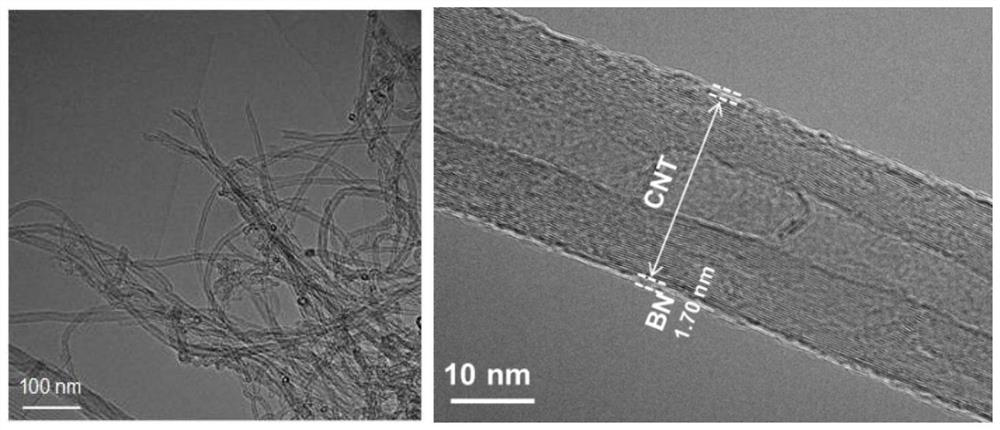

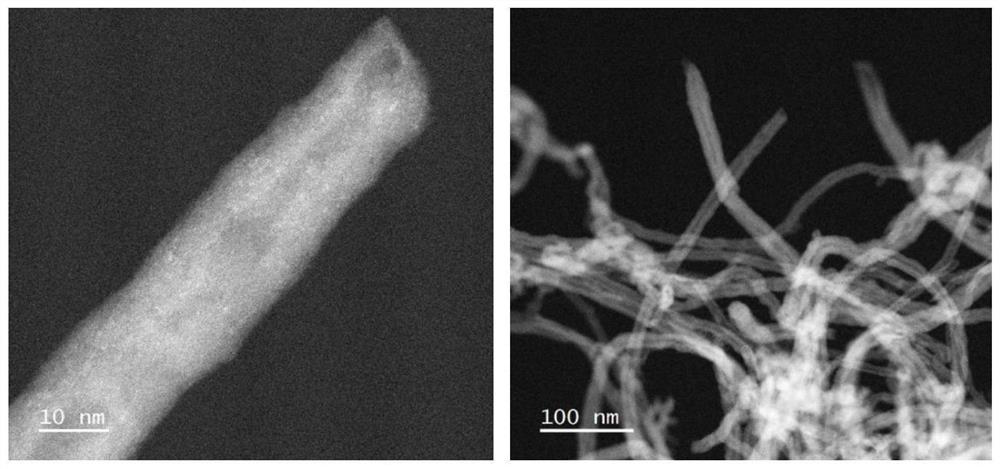

[0044] Example 1: Preparation of Co@e-BN@CNT

[0045] Urea, boric acid and carbon nanotubes (molar ratio of 5: 1: 10) were mixed and ground, and treated at a constant temperature of 1050 °C in a mixed atmosphere of ammonia and argon for 2 hours. The obtained powder was heated and stirred in a 0.5 mol / L boric acid solution at 90 °C for 30 minutes to obtain an etched boron nitride composite material. The etched boron nitride composite material was washed with deionized water and dried in a vacuum oven at 60° C. to obtain a defect-rich boron nitride composite material. The dried defect-rich boron nitride composites were immersed in an aqueous solution of cobalt nitrate and ultrasonicated for 5 hours. After vacuum freeze-drying, they were heated to 750°C at a heating rate of 10°C / min under a mixed atmosphere of ammonia and argon, and treated at a constant temperature for 2 hours. Then, naturally cooled to room temperature, and after pyrolysis annealing, a uniformly distributed at...

Embodiment 2

[0047] Example 2: Electrocatalytic OER performance test of Co@e-BN@CNT

[0048] The electrocatalytic OER performance test of the Co@e-BN@CNT obtained in Example 1 was carried out on an electrochemical workstation (CHI 760E, Shanghai Chenhua) using a traditional three-electrode system. Among them, the electrolyte was 1.0 M KOH aqueous solution, and the platinum sheet electrode and the Hg / HgO electrode were used as the counter electrode and the reference electrode, respectively. 3 mg of Co@e-BN@CNT was dispersed in 72 μL of deionized water, 48 μL of isopropanol and 10 μL of Nafion mixed solution. After sonication for 1 hour, the sample was dropped onto a glassy carbon electrode as a working electrode. Depend on Figure 4 It can be seen that Co@e-BN@CNT drives 10 mA cm -2 The current density overpotential is only 287 mV. Figure 5 The Tafel plot shown is based on Figure 4 It can be seen from the calculation that the Tafel slope of Co@e-BN@CNT on the platinum carbon electrode...

Embodiment 3

[0049] Example 3: Electrocatalytic ORR performance test of Co@e-BN@CNT

[0050] The electrocatalytic OER performance test of the Co@e-BN@CNT obtained in Example 1 was carried out on an electrochemical workstation (CHI 760E, Shanghai Chenhua) using a traditional three-electrode system. Among them, the electrolyte is an oxygen-saturated 1.0 M KOH aqueous solution, and the platinum sheet electrode and the Hg / HgO electrode are used as the counter electrode and the reference electrode, respectively. 3 mg of Co@e-BN@CNT was dispersed in 72 μL of deionized water, 48 μL of isopropanol and 10 μL of Nafion mixed solution. After sonication for 1 hour, the samples were dropped onto glassy carbon electrodes and cobalt foams as working electrodes. Depend on Figure 7 It can be seen that the initial potential of Co@e-BN@CNT is 0.864 V and the half-wave potential is 0.822 V when the rotation speed is 1600 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com