Defect-rich Fe2O3-FeF2 nano porous film, preparation method and application thereof

A fe2o3-fef2, nano-porous technology, applied in chemical instruments and methods, catalyst activation/preparation, electrodes, etc., can solve the problems of complex preparation process, long preparation cycle, high reaction temperature, etc., and achieve high preparation efficiency and short preparation cycle , the effect of high degree of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

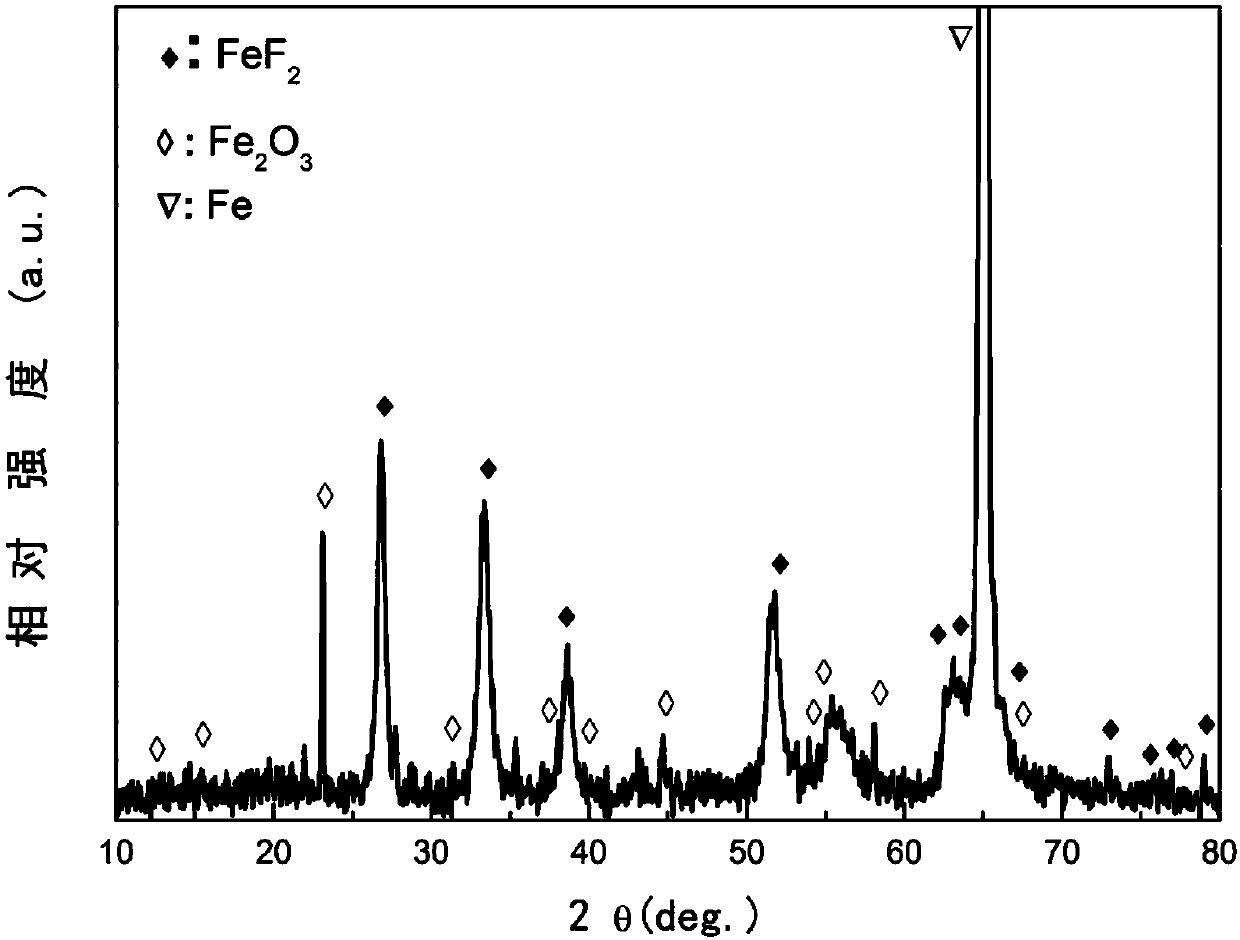

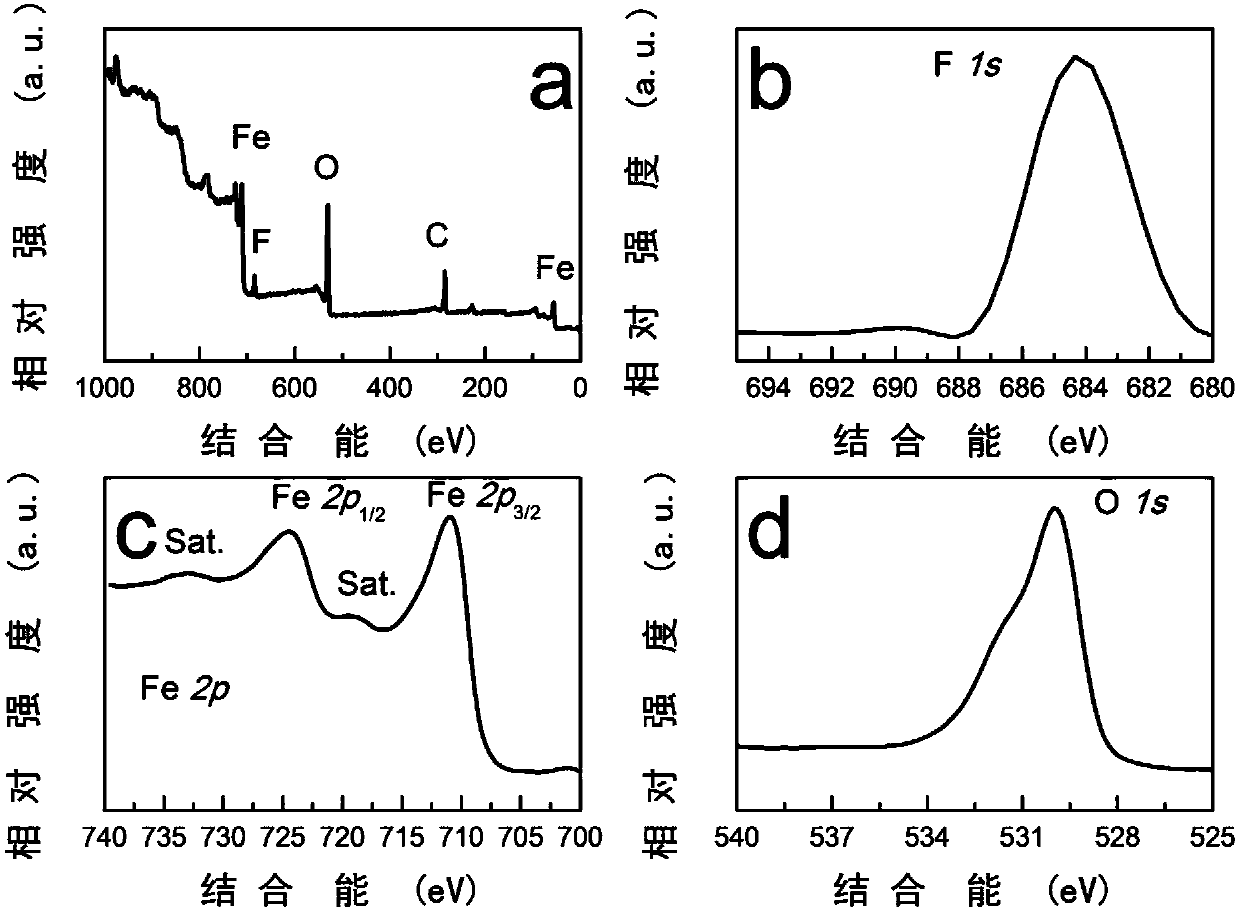

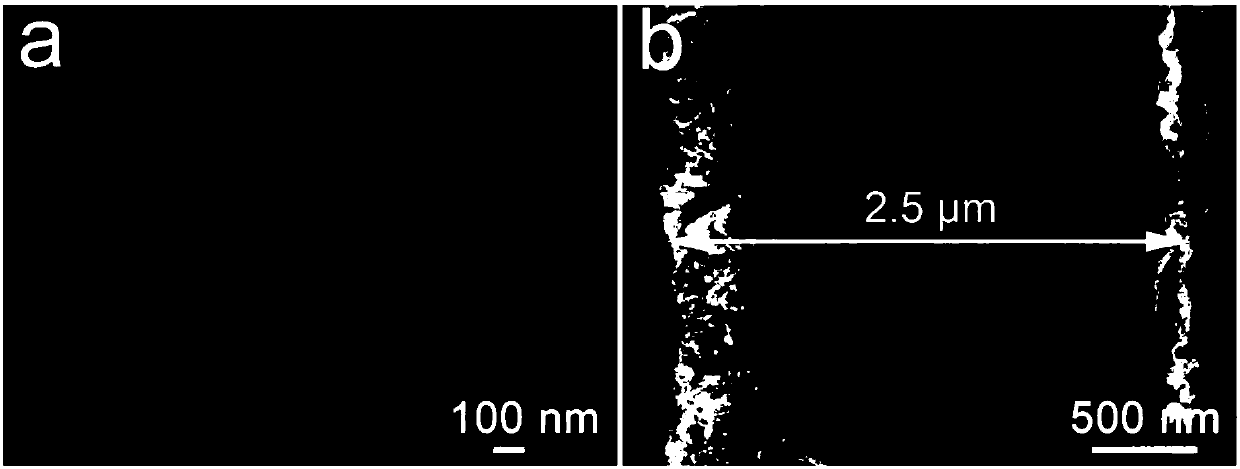

[0034] A kind of defect-rich Fe in this embodiment 2 o 3 -FeF 2 nanoporous films, the defect-rich Fe 2 o 3 -FeF 2 Nanoporous film based on iron foil, Fe 2 o 3 and FeF 2 grown on iron foil, and the defect-rich Fe 2 o 3 -FeF 2 The nanoporous film has a pore size of 40 nm.

[0035] The defect-rich Fe in the above examples 2 o 3 -FeF 2 The preparation method of nanoporous film, comprises the following steps:

[0036] (1) Put the iron foil in isopropanol and acetone in turn for ultrasonic cleaning, and dry it under nitrogen;

[0037] (2) Anodic oxidation: use the iron foil dried in step (1) as an anode, and another platinum sheet as a counter electrode to contain 0.1MNH 4 F. The ethylene glycol solution of 1.0M deionized water is used as the electrolyte to form a two-electrode system. Under a constant voltage of 35V, anodic oxidation treatment is carried out for 40 minutes to obtain a porous iron oxide film;

[0038] (3) CVD fluorination reaction: under the conditio...

Embodiment 2

[0041] A kind of defect-rich Fe in this embodiment 2 o 3 -FeF 2 nanoporous films, the defect-rich Fe 2 o 3 -FeF 2 Nanoporous film based on iron foil, Fe 2 o 3 and FeF 2 grown on iron foil, and the defect-rich Fe 2 o 3 -FeF 2 The nanoporous film has a pore size of 45 nm.

[0042] The defect-rich Fe in the above examples 2 o 3 -FeF 2 The preparation method of nanoporous film, comprises the following steps:

[0043] (1) Put the iron foil in isopropanol and acetone in turn for ultrasonic cleaning, and dry it under nitrogen;

[0044] (2) Anodic oxidation: use the iron foil dried in step (1) as an anode, and another platinum sheet as a counter electrode to contain 0.095M NH 4 F. The ethylene glycol solution of 1.0M deionized water is used as the electrolyte to form a two-electrode system. Under a constant voltage of 40V, anodic oxidation treatment is carried out for 40min to obtain a porous iron oxide film;

[0045] (3) CVD fluorination reaction: under the conditions...

Embodiment 3

[0048] A kind of defect-rich Fe in this embodiment 2 o 3 -FeF 2 nanoporous films, the defect-rich Fe 2 o 3 -FeF 2 Nanoporous film based on iron foil, Fe 2 o 3 and FeF 2 grown on iron foil, and the defect-rich Fe 2 o 3 -FeF 2 The nanoporous film has a pore size of 48 nm.

[0049] A kind of defect-rich Fe in the above-mentioned embodiment 2 o 3 -FeF 2 The preparation method of nanoporous film, comprises the following steps:

[0050] (1) Put the iron foil in isopropanol and acetone in turn for ultrasonic cleaning, and dry it under nitrogen;

[0051] (2) Anodic oxidation: use the iron foil dried in step (1) as an anode, and take another platinum sheet as a counter electrode to contain 0.15M NH 4 F. The ethylene glycol solution of 1.1M deionized water is used as the electrolyte to form a two-electrode system. Under a constant voltage of 42V, anodic oxidation treatment is carried out for 40 minutes to obtain a porous iron oxide film;

[0052] (3) CVD fluorination rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com