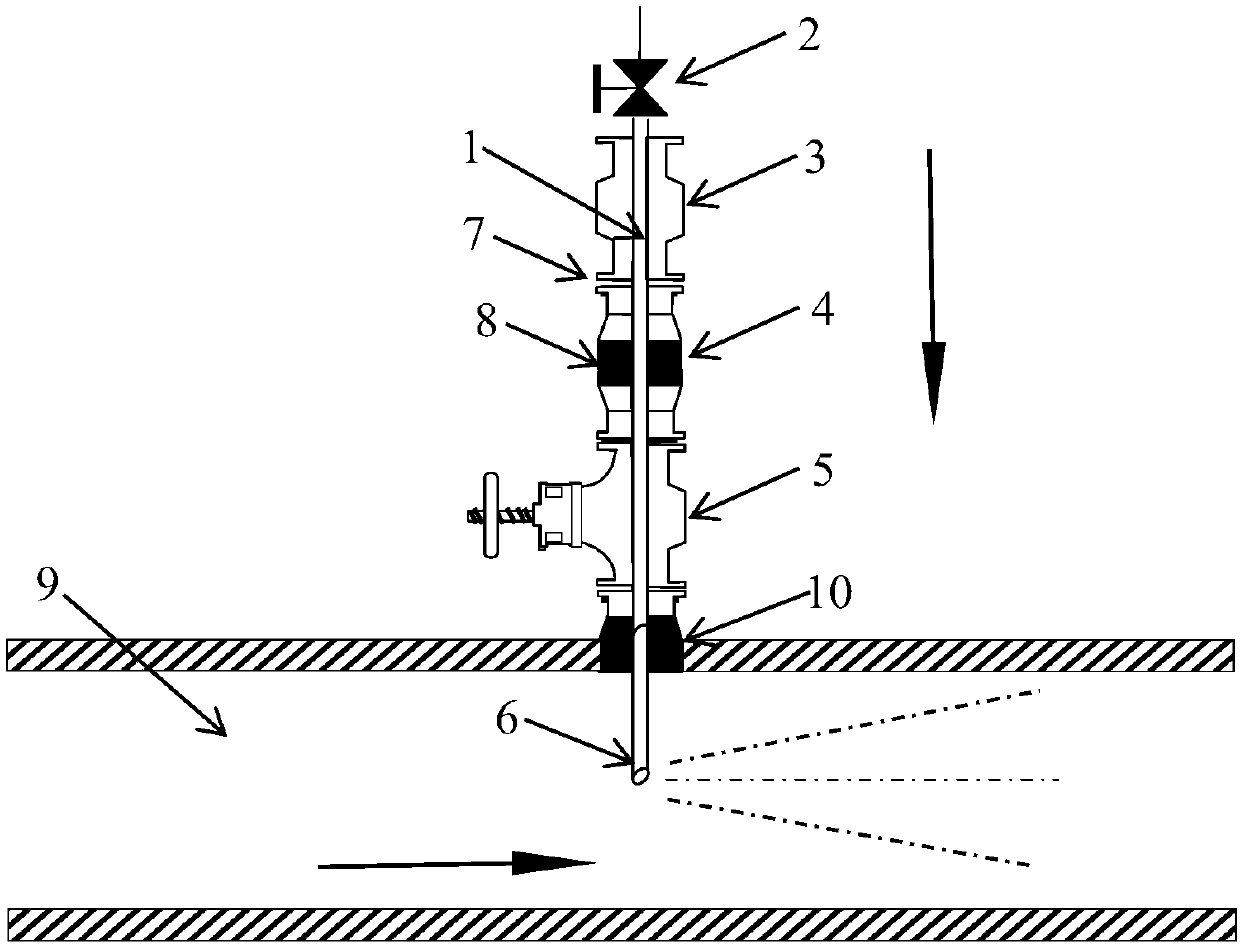

Assistant for removing unknown black suspended solid particles in crude oil and jet nozzle device for assistant filling

A solid particle and nozzle device technology, which is applied in the fields of refined hydrocarbon oil, petroleum industry, transportation and packaging, etc. It can solve the problems of high current, scaling of trays, dehydration and blackening of electric desalination devices, etc., and achieve a scientific and reasonable ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Unidentified black suspended solid particle removal aid in crude oil, including the following raw materials: propylene glycol block polyether L6435g, glutaraldehyde 1g, α-olefin sulfonate 8g, polyethylene glycol 600 15g, ethylene-vinyl acetate copolymer ( Vinyl acetate content 32%, its molecular weight 3100, degree of branching (7) 15g, solvent naphtha (flash point 120 ℃) 26g.

Embodiment 2

[0042] Unidentified black suspended solid particle removal aid in crude oil, including the following raw materials: propylene glycol block polyether F6835g, glutaraldehyde 1g, α-olefin sulfonate 8g, polyethylene glycol 600 15g, ethylene-vinyl acetate copolymer ( The content of vinyl acetate is 35%, its molecular weight is 3200, the degree of branching is 7) 15g, solvent naphtha (flash point 120°C) 26g, EDTA sodium salt 6g.

Embodiment 3

[0044] Unidentified black suspended solid particle removal aid in crude oil, including the following raw materials: propylene glycol block polyether F6830g, glutaraldehyde 3g, α-olefin sulfonate 10g, polyethylene glycol 500 12g, ethylene-vinyl acetate copolymer ( Vinyl acetate content 40%, its molecular weight 3200, degree of branching (7) 12g, mineral spirits (flash point 130 ℃) 30g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com