Preparation method of loaded type silver catalyst for formaldehyde purification

A technology for the purification of supported silver and formaldehyde, which is used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. problem, to achieve high formaldehyde purification effect, low cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

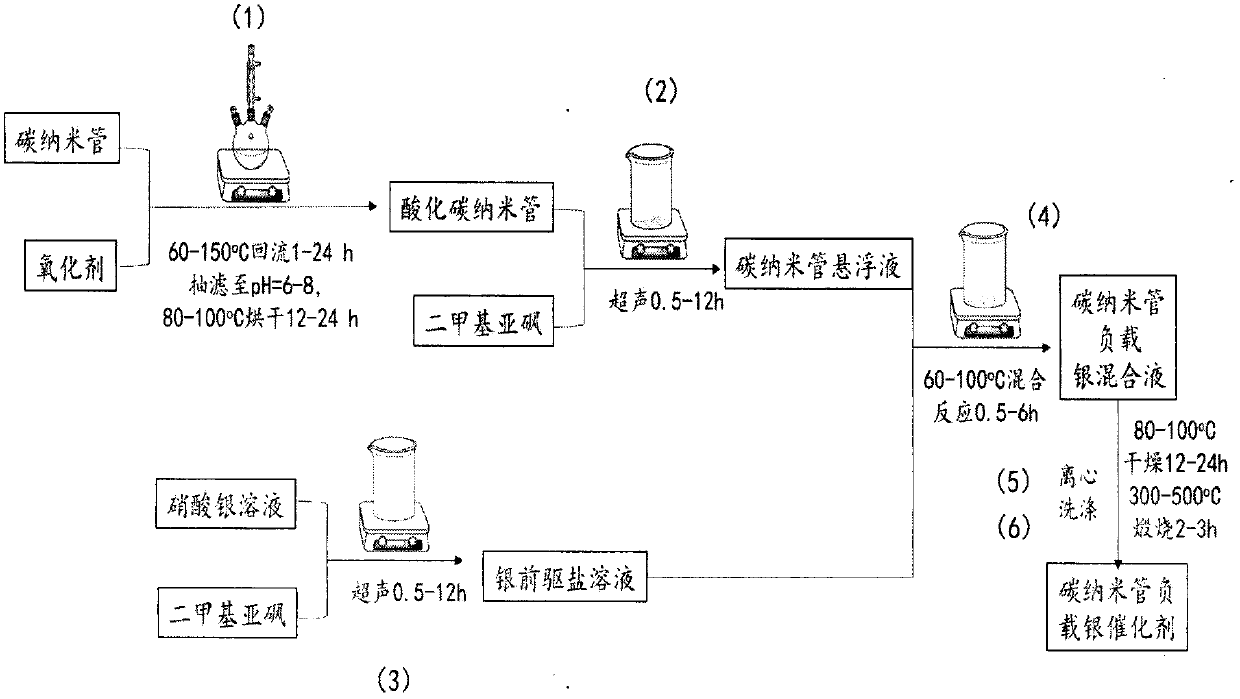

[0031] Such as figure 1 Shown: the preparation method flow process of supported silver catalyst provided by the present invention mainly comprises following 6 steps:

[0032] (1), carbon nanotube acid treatment

[0033] Weigh a certain amount of CNT and add it to the oxidant, such as KMnO 4 or H 2 o 2 or HNO 3 or H 2 SO 4 or HCl in a three-necked flask, select different temperatures of 60-150°C and different reflux times of 1-24h, and carry out acid oxidation reflux treatment on CNT. It is colorless and has a pH of 6-8. Then put the suction-filtered solid powder in an oven and dry it at 80-100°C for 12-24 hours to prepare the acid-oxidized CNT sample;

[0034] (2), preparation of carbon nanotube suspension

[0035] Add the above acid-oxidized CNT sample into the organic solvent dimethyl sulfoxide DMSO, and sonicate for 0.5-12 hours to obtain a carbon nanotube suspension with a concentration of 30-500 mg / mL;

[0036] (3), preparation of silver precursor salt solution ...

Embodiment 1

[0044] (1), carbon nanotube acid treatment

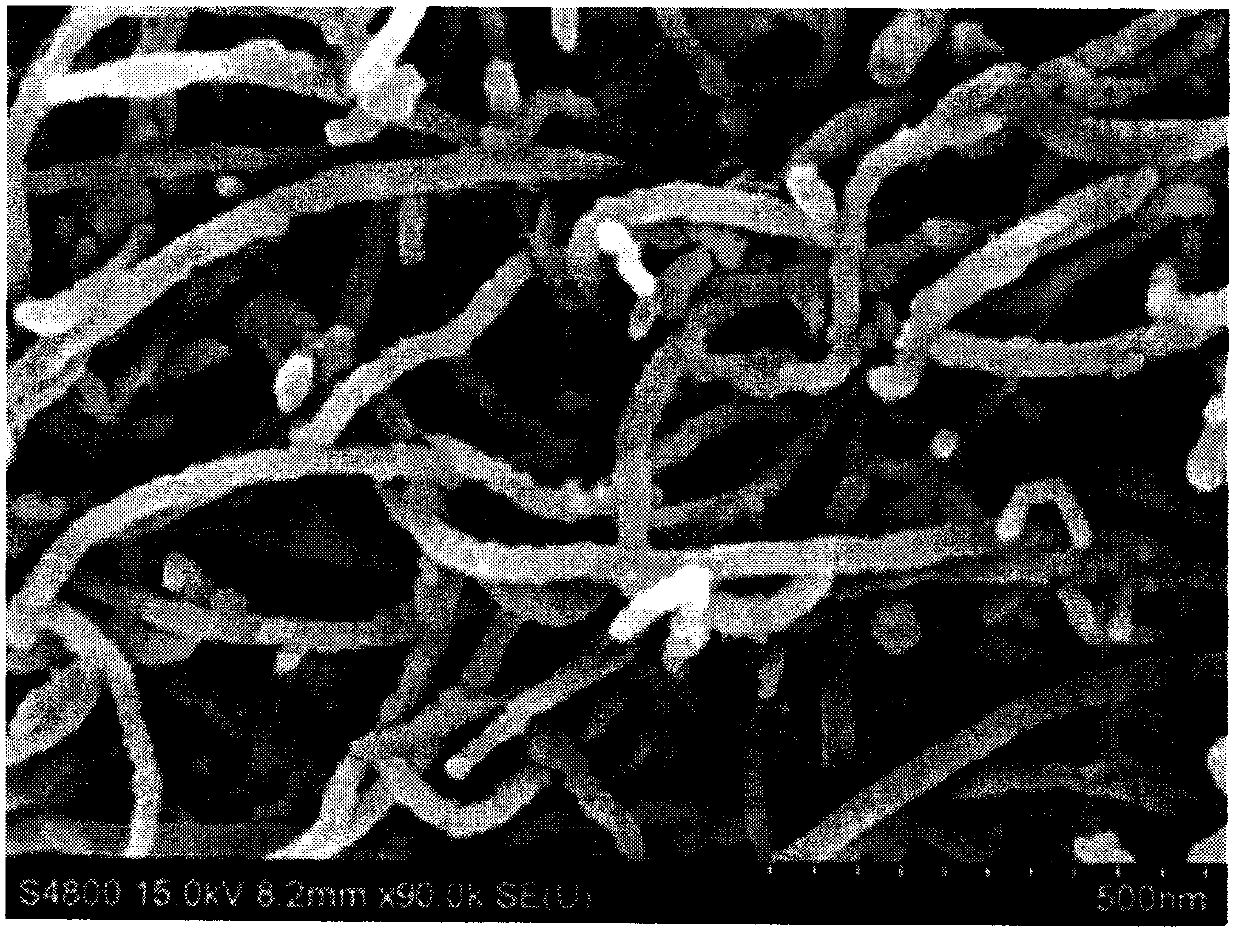

[0045] Weigh 1.0g CNTs and add to the oxidant HNO 3 In a three-neck flask, select the reflux temperature of 60 ° C and the oxidation reflux time of 1 h to carry out acid oxidation treatment on CNTs. After the reflux is finished and the solution obtained from the reaction is cooled to room temperature, the obtained solution is suction filtered and washed until the filtrate obtained is colorless and has pH=7, then the solid powder obtained by the suction filtration is placed in an oven, After drying at 80°C for 12 hours, the CNTs samples treated with nitric acid oxidation can be prepared, and the scanning electron microscope photos are shown in figure 2 .

[0046] (2), preparation of carbon nanotube suspension

[0047] Add 1.0 g of the above acid-oxidized CNTs sample into 30 mL of dimethyl sulfoxide, and ultrasonicate for 0.5 h to obtain a suspension of carbon nanotubes.

[0048] (3), preparation of silver precursor salt solution...

Embodiment 2

[0056] (1), carbon nanotube acid treatment

[0057] Weigh 1.0g CNTs and add to the oxidant H 2 SO 4 In a three-neck flask, select the reflux temperature of 60 ° C and the oxidation reflux time of 1 h to carry out acid oxidation treatment on CNTs. After the reflux is finished and the solution obtained from the reaction is cooled to room temperature, the obtained solution is suction filtered and washed until the filtrate obtained is colorless and has pH=7, then the solid powder obtained by the suction filtration is placed in an oven, After drying at 80°C for 12 hours, the acid-oxidized CNTs samples can be prepared, and the scanning electron microscope photos are shown in Figure 5 .

[0058] The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com