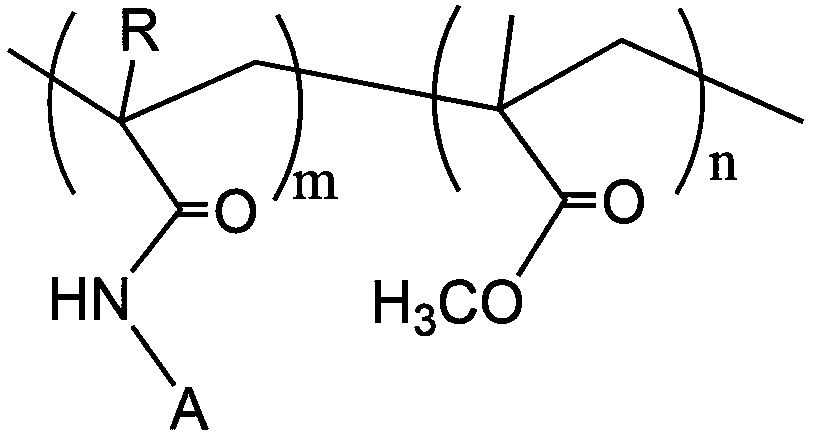

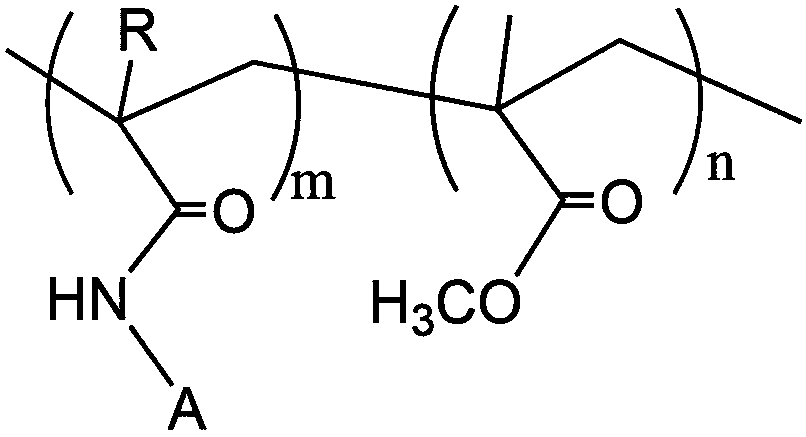

PMMA fluorescence copolymer microsphere and preparation method thereof

A copolymer and fluorescence technology, which is applied in the field of PMMA fluorescent copolymer microspheres, can solve the problems of poor oil solubility and unsuitability of fluorescent microspheres, and achieve the effects of long-lasting fluorescence, not easy to dissociate, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

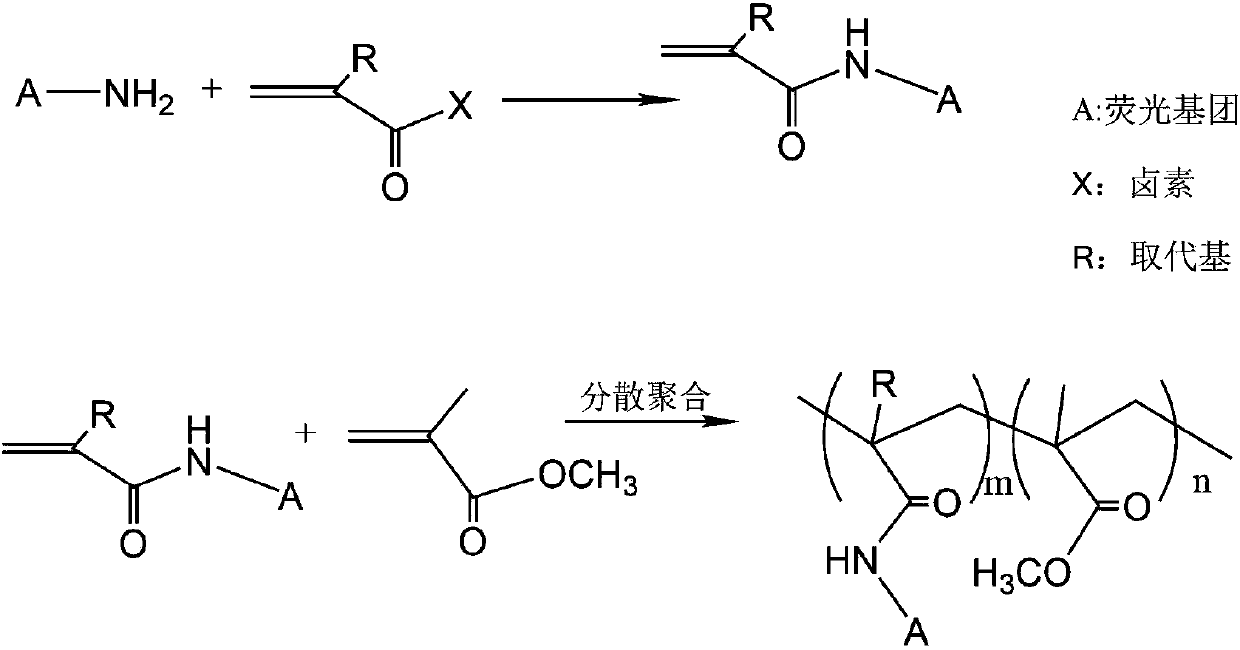

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of PMMA fluorescent copolymer microspheres, the steps are as follows:

[0026] a. Synthesis of modified fluorescent monomer: under nitrogen protection, 30 parts of 2-aminoanthraquinone, 1 part of triethylamine, Add 100 parts of acetone to the reactor to dissolve evenly, slowly drop in 14 parts of methacryloyl chloride, drop it in 2 hours, then continue to react at 80°C for 6 hours, filter the insoluble matter, spin the solution to remove the solvent, wash and dry to obtain the modified fluorescence monomer.

[0027] b. Dispersion polymerization PMMA fluorescent copolymer microsphere dispersion liquid: 10 parts of modified fluorescent monomer in step (1) are dissolved in 40 parts of methyl methacrylate, add 2 parts of polyvinylpyrrolidone, 80 parts of water, Disperse evenly through a disperser at a high speed, and record it as liquid a; take 0.5 parts of ammonium persulfate and completely dissolve it in 10 parts of methanol solvent to obtain an init...

Embodiment 2

[0030] A preparation method of PMMA fluorescent copolymer microspheres, the steps are as follows:

[0031] a. Synthesis of modified fluorescent monomer: 30 parts of 1,2-diaminoanthraquinone, 0.5 part of three Add ethanolamine and 100 parts of DMF to the reactor to dissolve evenly, slowly drop in 10 parts of maleic anhydride for 1 hour, then continue to react for 4 hours at 120°C, filter the insoluble matter, spin evaporate the solution, remove the solvent, wash and dry to obtain the modified product fluorescent monomer.

[0032] b. Dispersion polymerization PMMA fluorescent copolymer microsphere dispersion liquid: 10 parts of modified fluorescent monomers in step (1) are dissolved in 40 parts of methyl methacrylate, add 0.8 parts of polyethylene glycol 800, 60 parts of water , disperse evenly through a disperser at high speed, and record it as liquid a; take 1.5 parts of AIBN and completely dissolve it in 15 parts of propanol solvent to obtain an initiator solution, which is ...

Embodiment 3

[0035] a. Synthesis of modified fluorescent monomer: under nitrogen protection, in a reaction kettle equipped with a stirrer, a condenser, a constant pressure feeding device and a thermometer, 30 parts of 2-naphthylamine, 2 parts of picoline, 100 Add 25 parts of DMSO into the reactor to dissolve evenly, slowly drop in 25 parts of p-vinylbenzoyl chloride, drop it over 1.2h, then continue the reaction at 95°C for 4.5h, filter the insoluble matter, spin the solution to remove the solvent, wash and dry to obtain Modified fluorescent monomer.

[0036]b. Dispersion polymerization of PMMA fluorescent copolymer microsphere dispersion liquid: dissolve 20 parts of the modified fluorescent monomer in step (1) in 40 parts of methyl methacrylate, add 1 part of TX305, 100 parts of water, and pass through the disperser Disperse evenly at high speed, and record it as liquid a; Dissolve 0.8 parts of sodium persulfate completely in 10 parts of water to obtain an initiator solution, which is rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com