Nano-grade temperature-resisting and salt-resisting cross-linked polymer microspheres and preparation method thereof

A cross-linked polymer, temperature-resistant and salt-resistant technology, used in drilling compositions, chemical instruments and methods, etc., can solve problems such as being unsuitable for high-temperature and high-salt oil fields, poor dispersion and stability, affecting oil recovery, etc. problem, to achieve the effect of reducing oil-water interfacial tension, strong solubilization ability, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

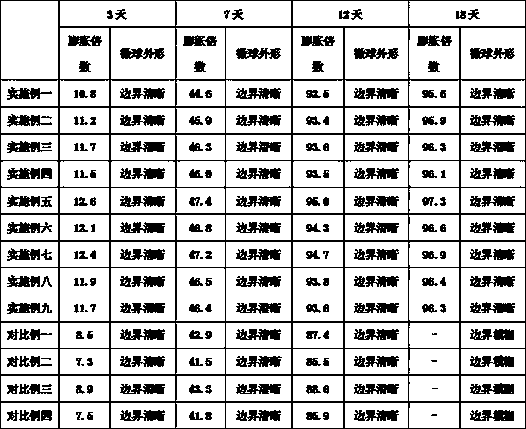

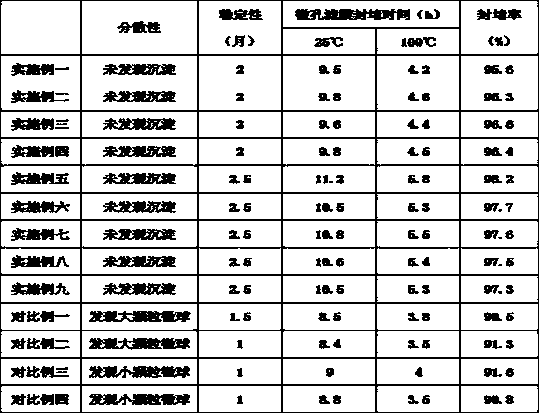

Examples

Embodiment 1

[0031] A nano-scale temperature-resistant and salt-resistant cross-linked polymer microsphere, which contains components and their contents: 40 parts by weight of acrylamide, 15 parts by weight of acrylic acid, 12 parts by weight of sodium 2-acrylamido-2-methylpropanesulfonate Parts by weight, 5 parts by weight of sorbitan oleate, 45 parts by weight of white oil, 1.5 parts by weight of polyethylene glycol, 0.6 parts by weight of zirconium nitrate, 6 parts by weight of dimethyl tetrachloroterephthalate, persulfuric acid 5.6 parts by weight of ammonium, 0.7 parts by weight of sulfur dioxide, 2 parts by weight of oligomeric silsesquioxane, 2.2 parts by weight of disodium edetate, 52 parts by weight of distilled water, and 8 parts by weight of acetone.

[0032] The preparation method of the nanoscale temperature-resistant and salt-resistant cross-linked polymer microspheres comprises the following steps:

[0033] 1) After mixing 40 parts by weight of acrylamide, 15 parts by weight...

Embodiment 2

[0039] A nano-scale temperature-resistant and salt-resistant cross-linked polymer microsphere, which contains components and their contents: 42 parts by weight of acrylamide, 16 parts by weight of acrylic acid, 13 parts by weight of sodium 2-acrylamido-2-methylpropanesulfonate Parts by weight, 6 parts by weight of polyoxyethylene sorbitan fatty acid ester, 47 parts by weight of white oil, 1.7 parts by weight of 1,2 propylene glycol, 0.7 parts by weight of zirconium nitrate, 6 parts by weight of dimethyl tetrachloroterephthalate , 5.8 parts by weight of ammonium persulfate, 0.8 parts by weight of sulfur dioxide, 3 parts by weight of polydimethylsiloxane, 2.4 parts by weight of disodium edetate, 55 parts by weight of distilled water, and 8 parts by weight of acetone.

[0040] The preparation method of the nanoscale temperature-resistant and salt-resistant cross-linked polymer microspheres comprises the following steps:

[0041] 1) After mixing 42 parts by weight of acrylamide, 1...

Embodiment 3

[0047] A nano-scale temperature-resistant and salt-resistant cross-linked polymer microsphere, which contains components and their contents: 48 parts by weight of acrylamide, 20 parts by weight of acrylic acid, 12 parts by weight of sodium 2-acrylamido-2-methylpropanesulfonate -22 parts by weight, 8 parts by weight of polyoxyethylene alkylphenol ether, 51 parts by weight of white oil, 2.6 parts by weight of glycerol, 1.2 parts by weight of zirconium nitrate, 9 parts by weight of dimethyl tetrachloroterephthalate, over 8 parts by weight of ammonium sulfate, 1.3 parts by weight of sulfur dioxide, 6 parts by weight of oligomeric silsesquioxane, 3.4 parts by weight of disodium edetate, 65 parts by weight of distilled water, and 10 parts by weight of acetone.

[0048] The preparation method of the nanoscale temperature-resistant and salt-resistant cross-linked polymer microspheres comprises the following steps:

[0049] 1) After mixing 48 parts by weight of acrylamide, 20 parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com