Method for producing citric acid fermentation liquor by two-stage fermentation

A citric acid fermentation liquid and stage technology, applied in the field of microbial fermentation, to achieve the effects of shortening the seed culture time, shortening the fermentation cycle, and improving the conversion rate of sugar and acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

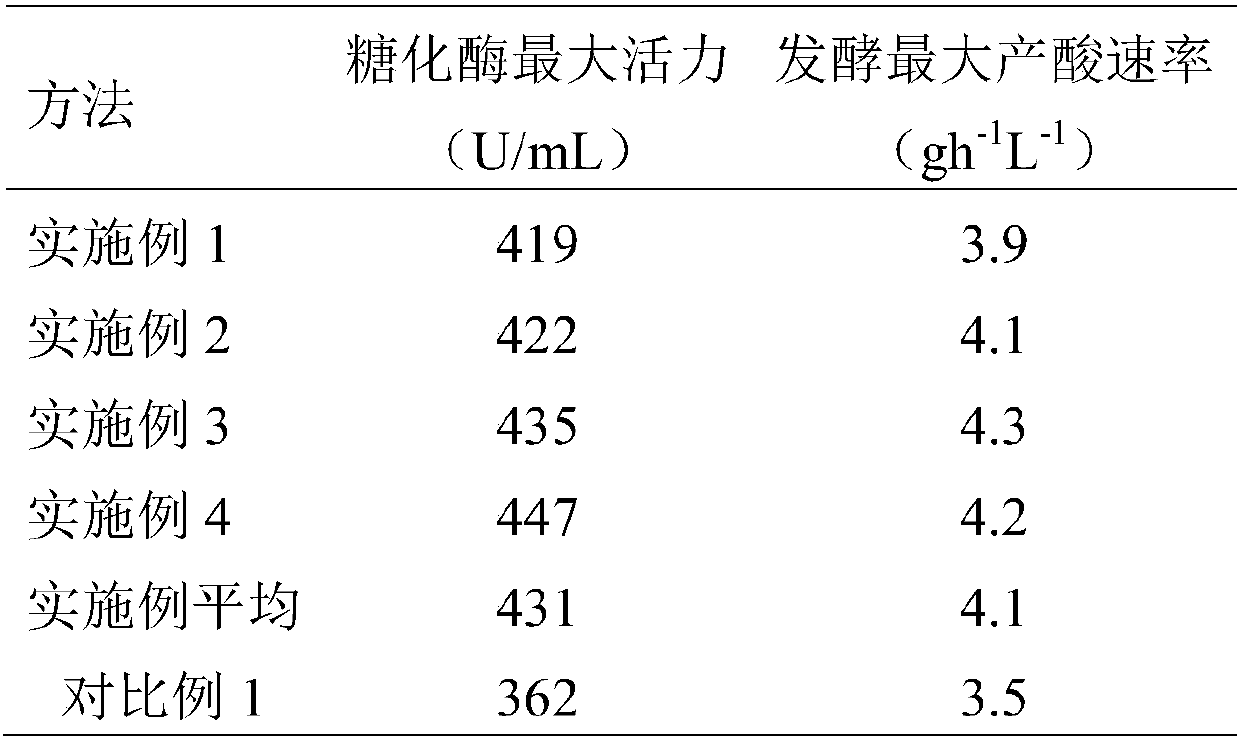

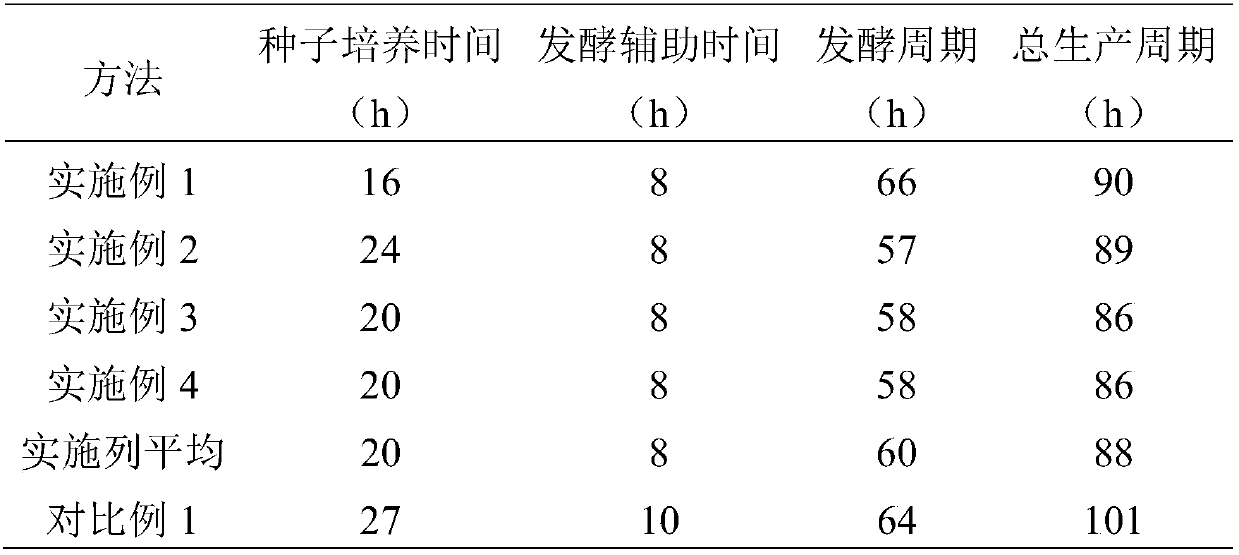

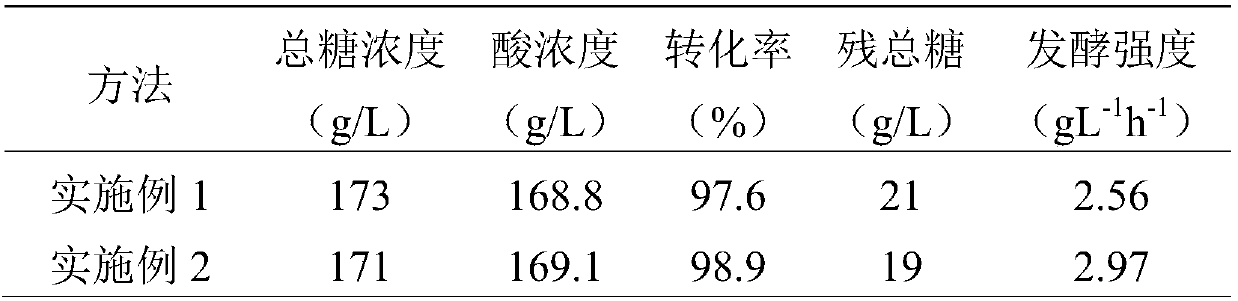

Examples

Embodiment 1

[0028] After crushing the corn, pass it through a 60-mesh sieve; mix the obtained corn flour with tap water at a mass ratio of 1:3, adjust the pH of the slurry to 6.0 with Ca(OH)2, and add 25 U / g of corn flour α—high-temperature amylase; the obtained slurry is first sprayed at 97°C, kept warm for 1.5 hours, then sprayed at 127°C, and the temperature of the feed liquid is reduced to 95°C after flash evaporation, and kept warm for 1 hour. After the iodine test is light brown, qualified corn liquefaction is obtained. liquid. The corn liquefaction solution is filtered through a plate frame to remove the filter residue to obtain the sugar solution.

[0029] Add 200L corn liquefaction solution and 100L tap water into the 500L seed tank as the seed medium. Take Aspergillus niger spores, add sterile water to make a spore suspension, transfer to a seed tank and cultivate for 16 hours to obtain a seed liquid.

[0030] In the first stage of fermentation, 400L of corn liquefaction liqui...

Embodiment 2

[0032] The preparation method of corn liquefaction liquid and sugar liquid is the same as that of Example 1, and the effects of seed cultivation and two-stage fermentation are mainly investigated.

[0033] Add 250L corn liquefaction solution and 150L tap water into the 500L seed tank as the seed medium. Take Aspergillus niger spores, add sterile water to make a spore suspension, transfer to a seed tank and cultivate for 24 hours to obtain a seed liquid.

[0034] In the first stage of fermentation, add 600L of corn liquefaction liquid into a 5000L fermenter, control the C / N at 15, lower the temperature to 39°C, transfer 400L of seed liquid to the fermenter for 2 hours; The liquid is first cooled by a plate heat exchanger outside the tank. After the temperature reaches 39°C, it is added to the fermenter, and the addition is completed within 12 hours. The volume of the sugar solution is 3000L. The C / N is controlled at 55, and the reducing sugar is lower than 5g / L. Stop Ferment t...

Embodiment 3

[0036] The preparation method of corn liquefaction liquid and sugar liquid is the same as that of Example 1, and the effects of seed cultivation and two-stage fermentation are mainly investigated.

[0037] Add 225L corn liquefaction solution and 125L tap water into the 500L seed tank as the seed medium. Take Aspergillus niger bran spores, add sterile water to make a spore suspension, transfer to a seed tank and cultivate for 20 hours to obtain a seed liquid.

[0038] In the first stage of fermentation, 500L of corn liquefaction liquid was added to a 5000L fermenter, and the C / N was controlled at 20. The liquid is first cooled by a plate heat exchanger outside the tank. After the temperature reaches 37°C, it is added to the fermentation tank, and the addition is completed within 6 hours. The volume of the sugar solution is 3100L. The C / N is controlled at 70, and the reducing sugar is lower than 5g / L. Stop Ferment to obtain citric acid fermentation liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com