Method for effectively improving yield and quality of single-layer 2D TMDCs

A technology of transition metal chalcogenides and compounds, applied in the field of materials, can solve problems such as crystal defects of two-dimensional layered crystals, quality degradation of single-layer two-dimensional materials, and influence on the gasification rate of reaction precursors, etc., to achieve improved safety and improved Yield, growth size improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

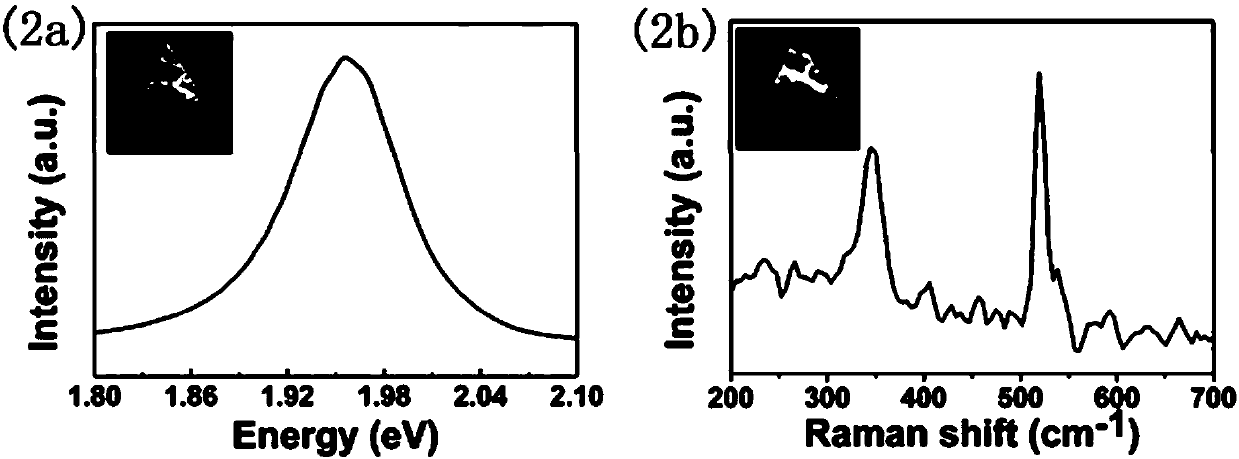

[0032] Example 1 A Method for Effectively Improving the Yield and Quality of Monolayer Two-dimensional Transition Metal Chalcogenides

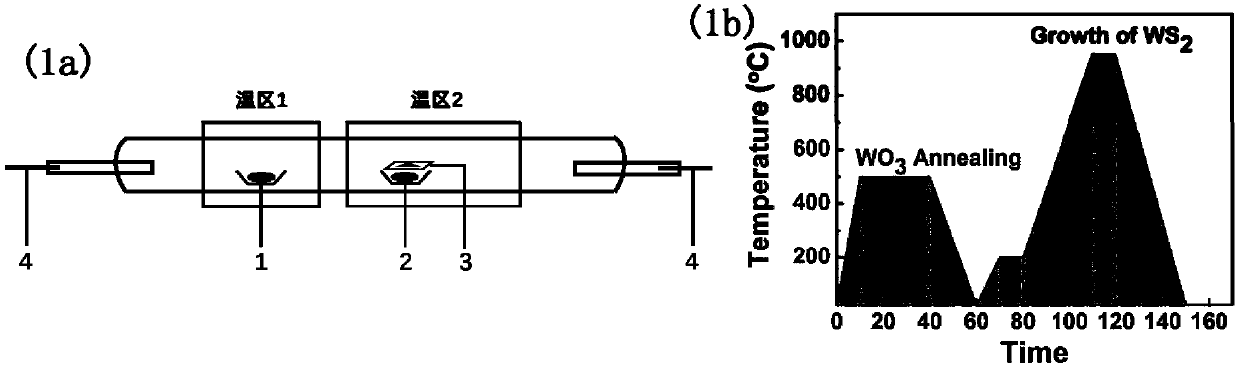

[0033] with WS 2 The preparation of is example, adopt the equipment shown in schematic diagram (1a), specifically comprise the following steps:

[0034] (1) Add 0.5g WO 3 Put it in the temperature zone 2 (high temperature zone) of the quartz tube and raise the temperature to 500°C. 3 The powder is annealed in the air for 30 minutes at normal pressure to fully oxidize it into W oxide WO 3-X ; Natural cooling to room temperature conditions;

[0035] (2) Clean the cut single-throw sapphire substrate and dry it for subsequent use;

[0036] (3) the WO prepared in step (1) 3-X Placed at position 2 in the quartz tube, place the single-polished sapphire substrate obtained in step (2) facing down on the WO 3-x above, that is, position 3; finally take S powder and place it in position 1 in the quartz tube;

[0037] (4) After the system is sealed, t...

Embodiment 2

[0042] Adopt the equipment shown in schematic diagram (1a), specifically comprise the following steps:

[0043] (1) Add 0.5g of WO 3 Installed in a quartz boat, placed in the center of the plasma generator, evacuated for 5 minutes, then turned on the RF power to the maximum, and introduced a small amount of air into the cavity, and this process lasted for 5 minutes;

[0044] (2) Clean the cut single-throw sapphire substrate and dry it for subsequent use;

[0045] (3) the WO prepared in step (1) 3-X Placed at position 2 in the quartz tube, place the single-polished sapphire substrate obtained in step (2) facing down on the WO 3-x above, that is, position 3; finally take S powder and place it in position 1 in the quartz tube;

[0046] (4) After the system is sealed, the whole system is first pumped to keep the pressure at 15torr and the argon flow rate at 100sccm;

[0047] (5) The heating and cooling of temperature zone 1 and temperature zone 2 are all carried out under the ...

Embodiment 3

[0049] Adopt the equipment shown in schematic diagram (1a), specifically comprise the following steps:

[0050] (1) Add 0.5g WO 3 Place it in the center of the plasma generator, vacuumize it for 5 minutes, then turn on the RF power to the maximum, and pass a small amount of air into the cavity, and this process lasts for 5 minutes;

[0051] (2) WO obtained by plasma treatment in step (1) 3-X Install it in a quartz boat, place it in the temperature zone 2 (high temperature zone) of the quartz tube, and raise the temperature to 500°C. 3 The powder was annealed at atmospheric pressure for 30 minutes in air to fully oxidize it into W oxide WO 3-X ; Natural cooling to room temperature conditions;

[0052] (3) cleaning the cut single-throw sapphire substrate and drying it for subsequent use;

[0053] (4) the WO prepared in step (2) 3-X Placed at position 2 in the quartz tube, place the single-polished sapphire substrate obtained in step (2) facing down on the WO 3-x above, tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com