Oxide-modified flexible composite sulfur positive electrode material and preparation method thereof

A sulfur cathode material and cathode material technology, which are applied in the field of flexible composite sulfur cathode materials and preparation, can solve the problems of reducing the relative content of active substances in the pole piece, limiting the energy density of the battery, poor conductivity of the binder, etc., so as to suppress the shuttle effect. , The effect of improving the mechanical strength of the electrode and improving the overall conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An oxide-modified flexible composite sulfur positive electrode, the specific steps are

[0037] 1) By the improved Hummers method, mix 4.0g graphite, 2.0g sodium nitrate and 92ml concentrated sulfuric acid evenly, slowly add 6.0g potassium permanganate at 0°C and stir for 1h. Then slowly raise the temperature to 35°C and keep it for 5h, add 1000ml of water to dilute, and keep it at 98°C for 15min, then add 400ml of 60°C distilled water to dilute. Add 20ml of 30% hydrogen peroxide solution to turn bright yellow, stir for 10 minutes, wash with 7% hydrochloric acid three times, and wash with distilled water until neutral, then dialyze for three days, centrifuge and wash until neutral, and freeze-dry for 48 hours to obtain graphene oxide;

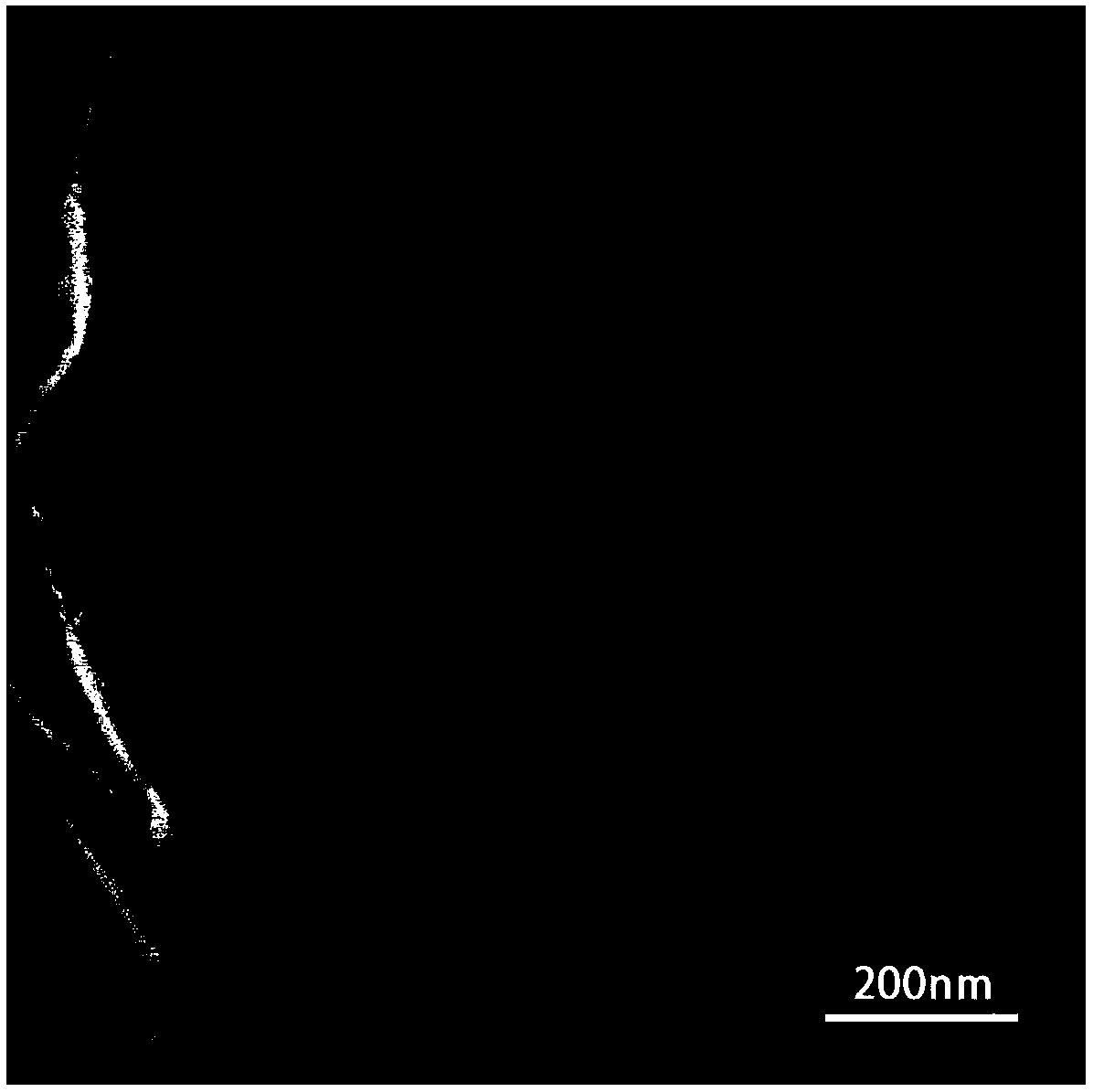

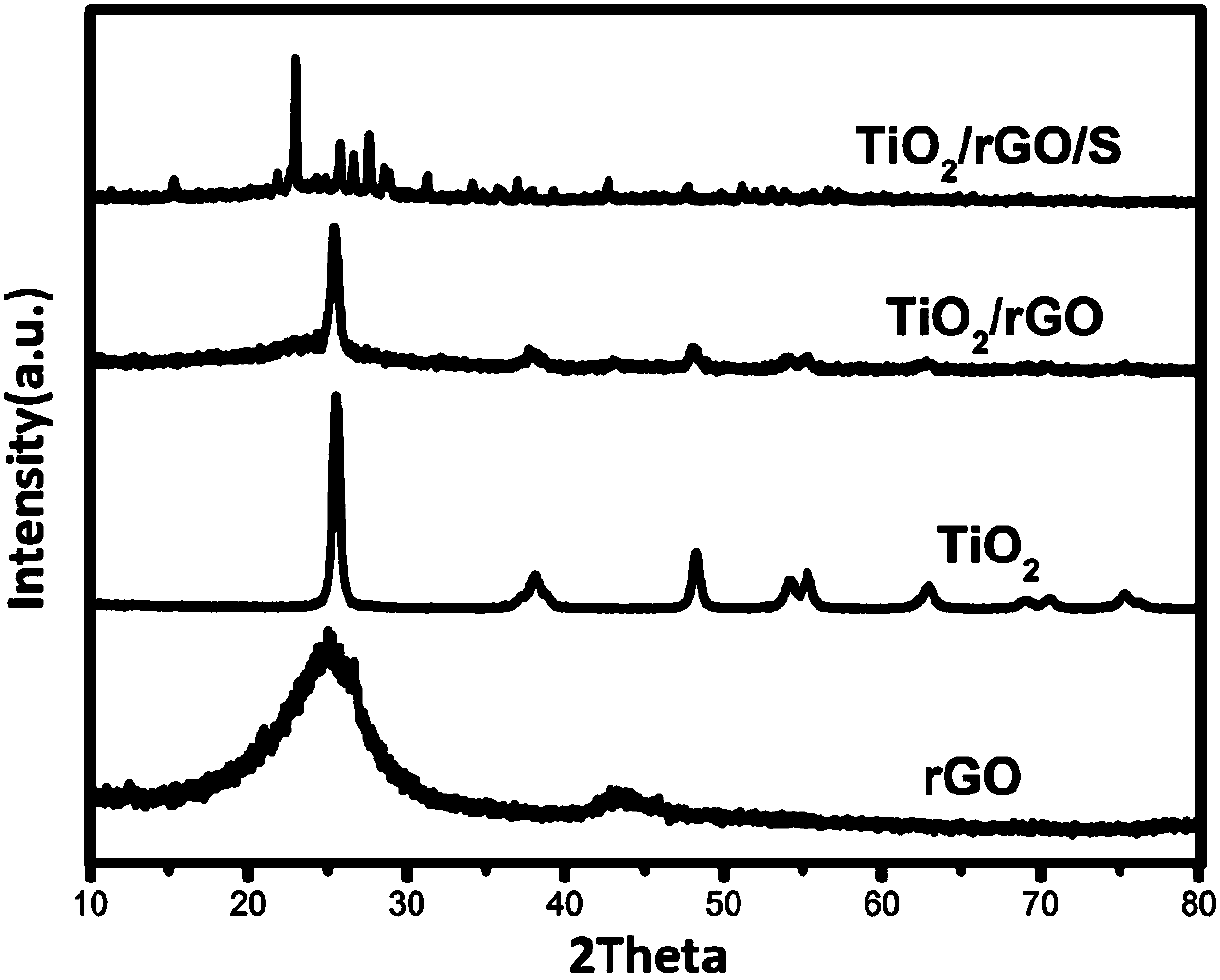

[0038] 2) Take 0.1 g of step 1) graphene oxide and put it in a beaker, add 80 ml of ethanol, and ultrasonically disperse the graphene oxide at room temperature for 12 hours to obtain a graphene oxide dispersion. Add 0.0852g of tetrabuty...

Embodiment 2

[0044] An oxide-modified flexible composite sulfur positive electrode, the specific steps are

[0045] 1) Get 0.14g of graphene oxide and 0.02g of carbon nanotubes and put them in a beaker, then add the mixed solution of 80ml of ethanol and water (V 乙醇 :V 水 =3:1), at room temperature, the graphene oxide and carbon nanotubes were uniformly dispersed by ultrasonication for 24 hours to obtain a GO / CNTs dispersion. Add 0.5g of zinc dioxide powder, and stir the solution evenly by magnetic stirring;

[0046]3) Transfer the solution obtained in 2) to a reaction kettle lined with polytetrafluoroethylene, and react in a vacuum oven at 98° C. for 2 hours;

[0047] 4) The composite material obtained in 3) was formed by vacuum suction filtration, and the filter cake was dried in a blast oven at 70°C for 5 hours to obtain TiO 2 / rGO / CNTs composite material; combining sublimated sulfur with ZnO 2 / rGO / CNTs composite materials were mixed, heated to 155 °C for 12 h in a closed container, ...

Embodiment 3

[0050] An oxide-modified flexible composite sulfur positive electrode, the specific steps are

[0051] 1) Put 0.06g of graphene oxide and 0.06g of carbon fiber in a beaker, add 80ml of propanol, and ultrasonically disperse the graphene oxide and carbon fiber at room temperature to obtain a graphene / carbon fiber dispersion. Add 0.6g of titanium dioxide, and stir the solution evenly by magnetic stirring;

[0052] 3) Transfer the solution obtained in 2) to a reaction kettle lined with polytetrafluoroethylene, and react in a vacuum oven at 180°C for 24 hours;

[0053] 4) The composite material obtained in 3) is formed by vacuum suction filtration, and the filter cake is dried in a blast oven at 80° C. for 2 hours to obtain a titanium dioxide / graphene / carbon fiber composite material;

[0054] 5) Soak the composite in CS dissolved in the active substance sulfur 2 solution, ultrasonic vibration at room temperature for 2 hours to prepare a titanium dioxide / graphene / carbon fiber / sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com