Method for preparing nano-alumina carrier with defect-rich surface

A nano-alumina, carrier technology, applied in catalyst carriers, chemical instruments and methods, catalyst activation/preparation, etc., to achieve the effects of excellent thermal stability and catalytic activity, simple synthesis process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

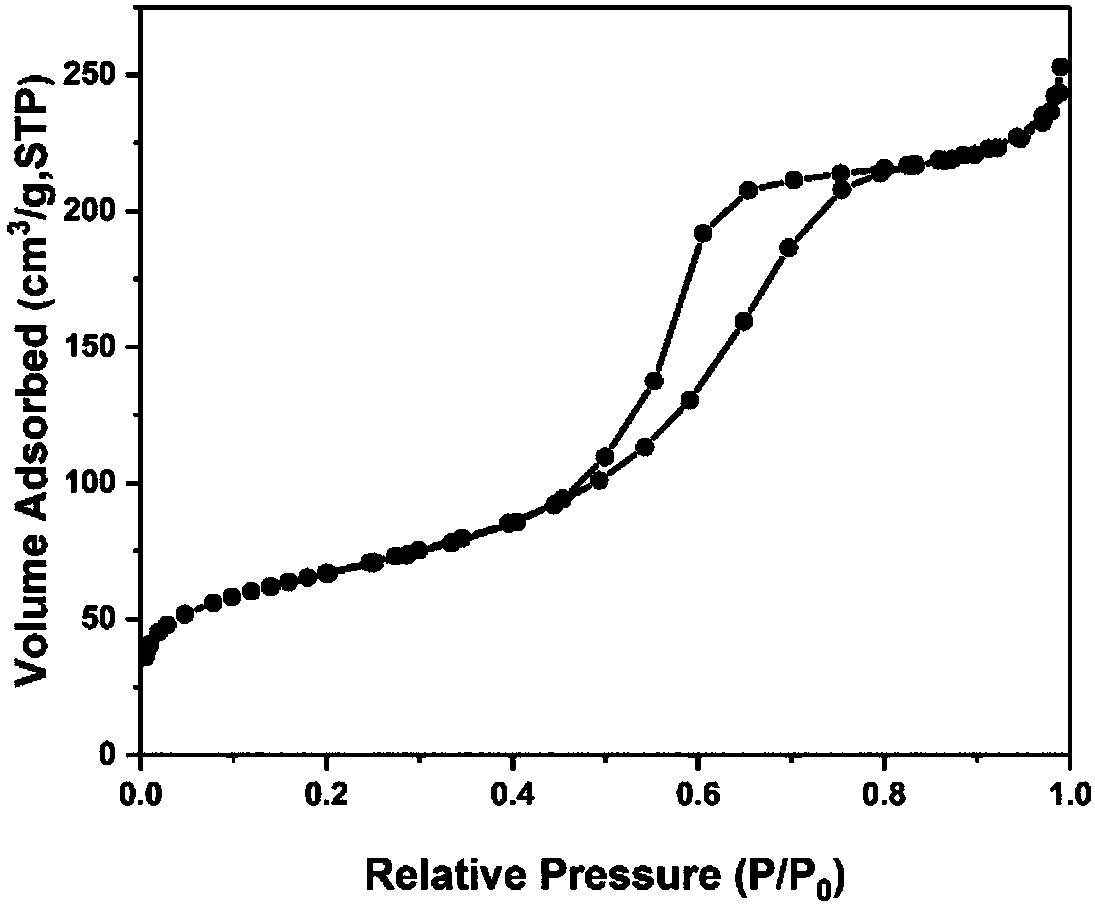

[0029] 0.02mol Al(NO 3 ) 3 9H 2 O and 0.12mol urea are placed in a beaker, the beaker is placed in a constant temperature water bath, and 25mL of deionized water and 5mL of ethylene glycol are slowly added to the beaker with a graduated cylinder, stirred at a constant speed, and the temperature is maintained at 30°C; the above solution is transferred to In a 50mL hydrothermal kettle, hydrothermally react in an oven at 100°C for 24h, cool down to room temperature naturally, wash to neutrality by centrifugation, and dry the product in an oven at 80°C overnight. The obtained white precipitate was calcined in a muffle furnace at 800° C. for 2 h at a heating rate of 1° C. / min to obtain a nanorod-shaped alumina carrier, and its scanning electron microscope is shown in FIG. 1 . Nitrogen adsorption test results show that the specific surface area is about 230m 2 / g, the pore volume is 0.40cm 3 / g, its nitrogen adsorption isotherm curve is as follows figure 2 shown.

Embodiment 2

[0031] 13.27mg H 2 PtCl 6 ·6H 2 O and 14.94 mg SnCl 2 2H 2 The O precursor was dissolved in 330 μL ethanol solution, and an equal volume of the above solution was impregnated onto 1 g of the carrier prepared in Example 1. After impregnation, the sample was allowed to stand at room temperature for 2 hours, and dried in an oven at 50° C. overnight. The obtained sample was heated in 20% O 2 / N 2 Roasting at 500°C for 4 hours in atmosphere to obtain PtSn / Al for propane dehydrogenation to propylene 2 O 3 catalyst.

Embodiment 3

[0033] Take 120 mg of the alumina carrier prepared in Example 1 and evenly disperse it in 6 mL of deionized water, add 735 μL of HAuCl 4 (4.9g / L) solution, after stirring for 10 minutes, add 200 μL precipitant (0.5M ammonium carbonate solution), and after the system is stable, place the mixed solution in a 60°C water bath for 2 hours. Centrifugal washing (4 times with deionized water, 1 time with ethanol) to remove chloride ions. Finally, vacuum dry overnight (the desiccant is P 2 O 5 ), that is, Au / Al oxidized by carbon monoxide 2 O 3 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com