A kind of preparation method of fe3o4 base biochar soil passivation agent

A technology of biochar and passivation agent, which is applied in the direction of chemical instruments and methods, restoration of polluted soil, soil conditioning materials, etc., can solve the problem of resistance to failure and the state of active sites that cannot meet the requirements of soil adsorption of heavy metals and migration of heavy metal ions slow, the removal effect is not obvious, etc., to achieve the effect of resource recycling, stability, good performance, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

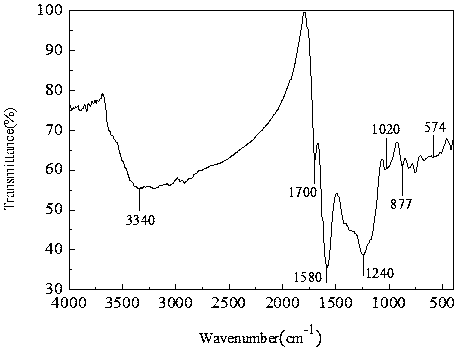

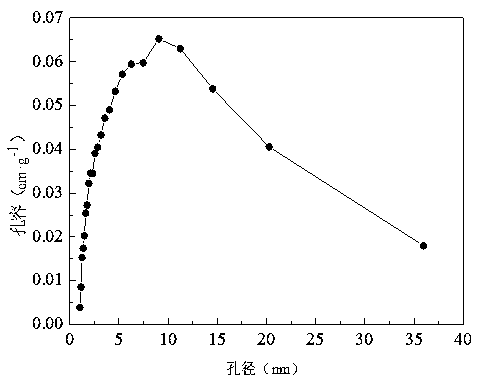

[0029] The present invention actually discloses a Fe 3 o 4 The preparation method of biochar-based soil passivator specifically includes the following steps:

[0030]Step 1. After crushing, sieving, cleaning and drying Xinjiang walnut shells, place them in an atmosphere furnace and carbonize them into biochar under a nitrogen atmosphere. The carbonization temperature is selected to be ≤500°C. The carbonization temperature is to prevent the carbonization temperature from being too high to cause denaturation of the biochar. The surface area and porosity of the biochar will decrease sharply and the effect of the heavy metal passivator will not be achieved (or the effect will not be good). The minimum value of the carbonization temperature is not required. It only needs to be able to carbonize walnut shells, and the temperature above or slightly lower than 280°C can be selected according to conventional technical solutions.

[0031] Step 2. Add the biochar obtained in step 1 to ...

Embodiment 1

[0038] a kind of Fe 3 o 4 The preparation method of base biochar soil passivator comprises the steps:

[0039] Step 1. After crushing, sieving, washing, and drying Xinjiang walnut shells, place them in an atmosphere furnace, and carbonize them into biochar in a nitrogen atmosphere. The carbonization temperature is 300°C, and the carbonization time is 4 hours;

[0040] Step 2: Add 200 g of the biochar prepared in Step 1 to the aqueous solution of acetic acid and acetylacetone for modification, heat and boil for 1 hour, in the aqueous solution of acetic acid and acetylacetone, the mass fraction of acetic acid is 5%, and the mass fraction of acetylacetone is 13.5% , The addition amount of the aqueous solution of acetic acid and acetylacetone is 600g. After the heating is completed, wash the biochar with distilled water until the liquid is neutral after washing, and dry it;

[0041] Step 3: Weigh a certain amount of FeCl 3 and FeCl 2 , according to the molar ratio n(Fe 3+ ):...

Embodiment 2

[0045] a kind of Fe 3 o 4 The preparation method of base biochar soil passivator comprises the steps:

[0046] Step 1. After crushing, sieving, washing, and drying Xinjiang walnut shells, place them in an atmosphere furnace, and carbonize them into biochar in a nitrogen atmosphere. The carbonization temperature is 400°C, and the carbonization time is 3 hours;

[0047] Step 2: Add 200 g of the biochar prepared in Step 1 into an aqueous solution of acetic acid and acetylacetone for modification, heat and boil for 2 hours, in the aqueous solution of acetic acid and acetylacetone, the mass fraction of acetic acid is 6%, and the mass fraction of acetylacetone is 15% %, the addition of the aqueous solution of acetic acid and acetylacetone is 800g. After the heating is completed, wash the biochar with distilled water until the liquid is neutral after washing, and dry it;

[0048] Step 3: Weigh a certain amount of FeCl 3 and FeCl 2 , according to the molar ratio n(Fe 3+ ): n(Fe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com