Low-temperature preparation method of strontium lanthanum aluminate composite material

A nano-composite material, lanthanum strontium aluminate technology, applied in the field of material manufacturing, can solve the problems of high preparation temperature, difficult to control, easy agglomeration and crystallization of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

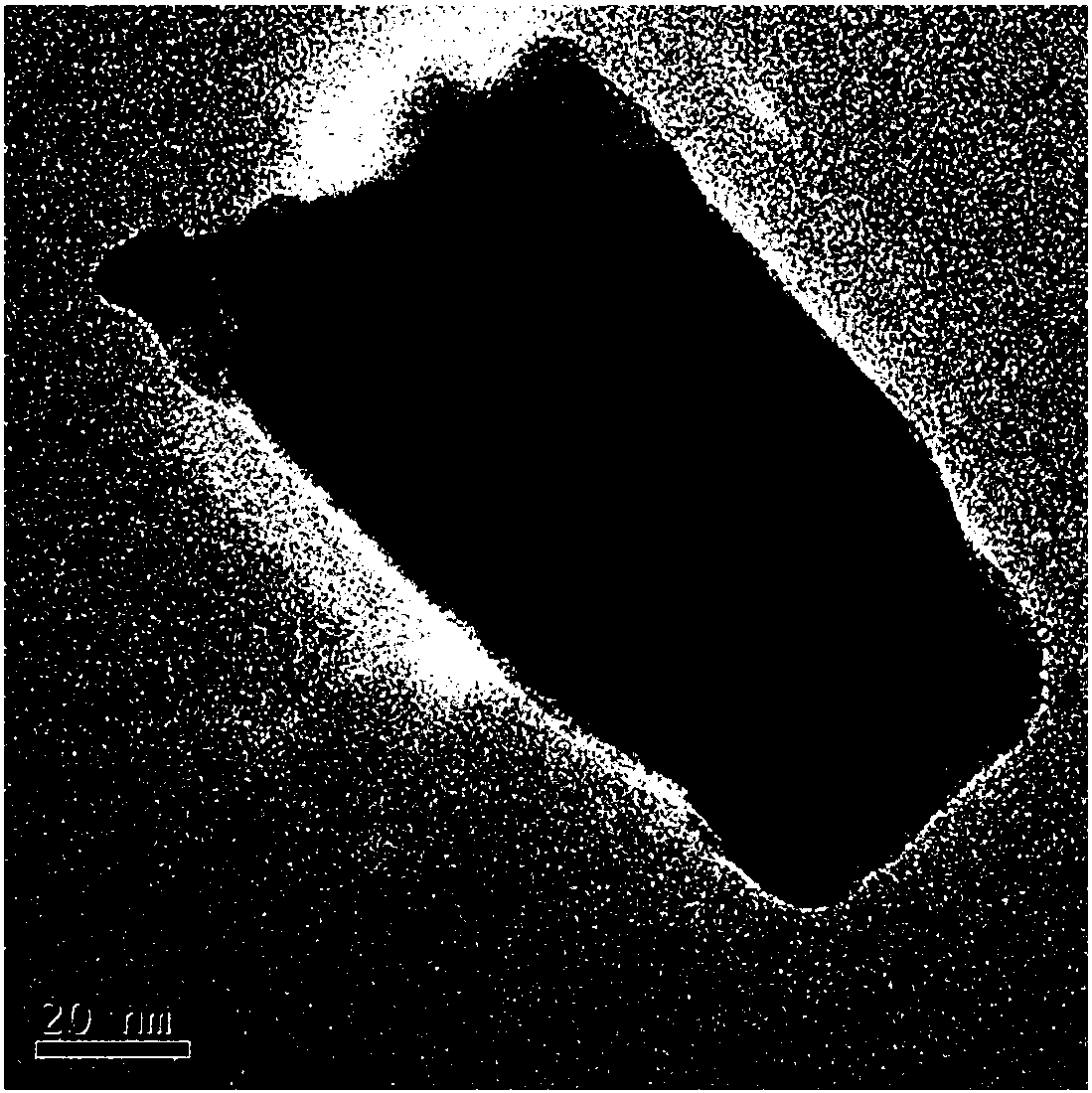

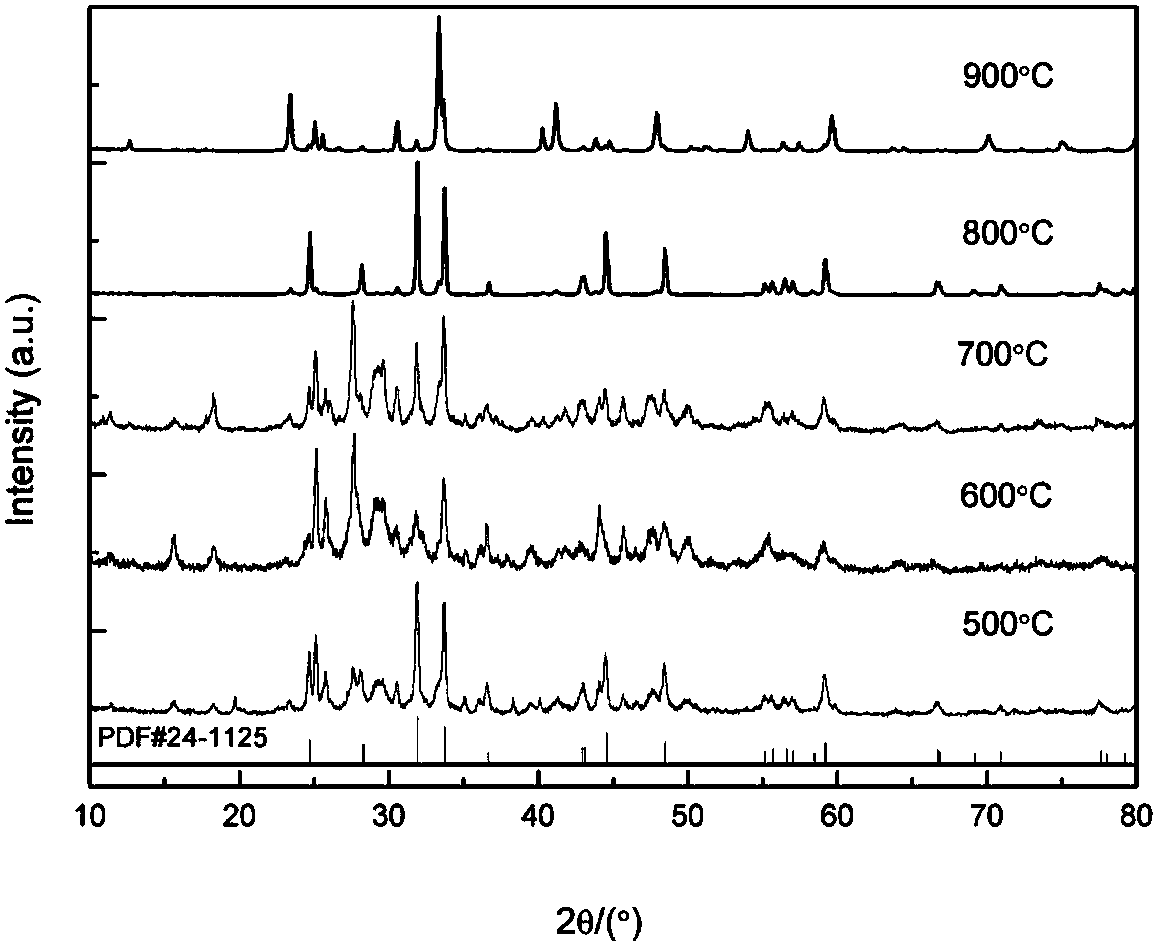

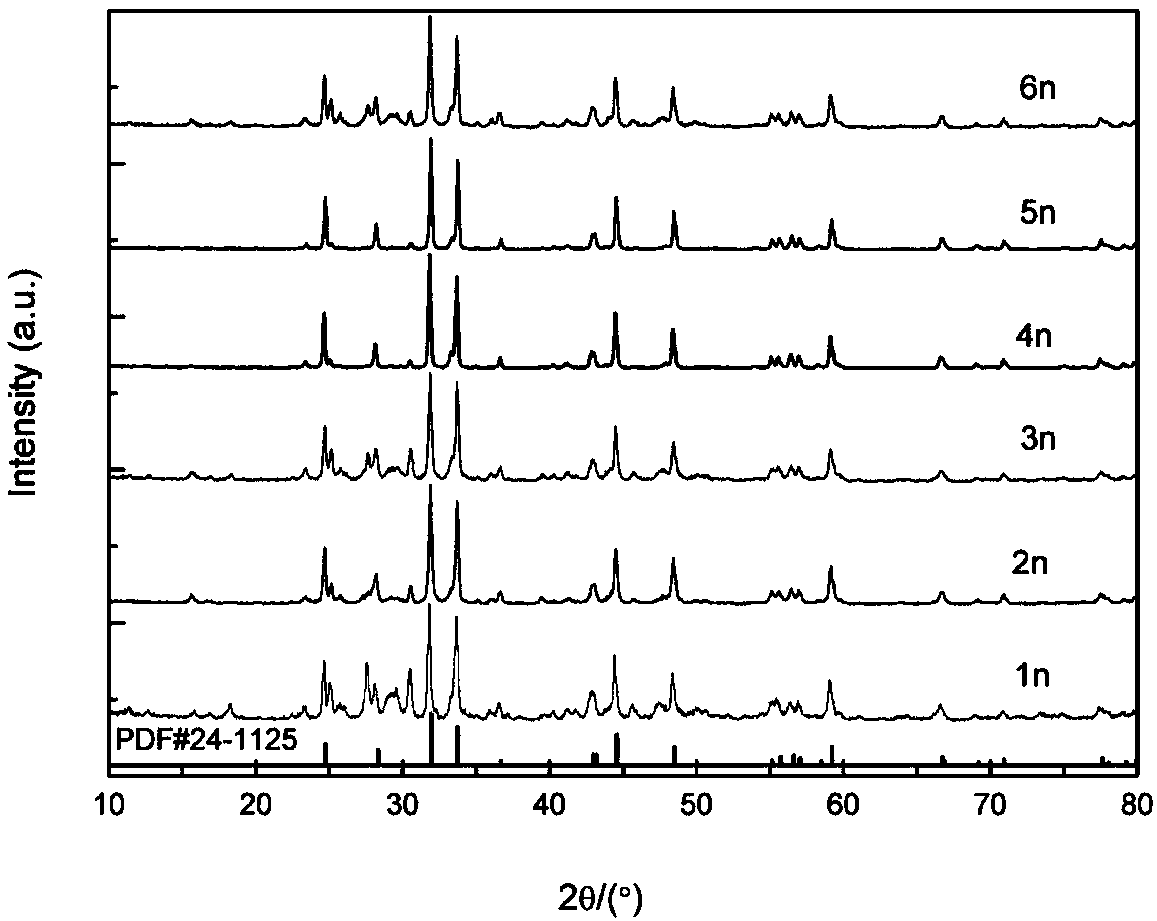

[0013] This embodiment provides a low-temperature preparation method of a strontium lanthanum aluminate nanocomposite material, comprising the following steps:

[0014] (1) Mix strontium salt solution, lanthanum salt solution, aluminum salt solution, organic fuel and complexing agent uniformly: press SrLaAlO 4 The stoichiometric ratio takes the Sr-containing compound, the La-containing compound and the Al-containing compound as raw materials, preferably, the raw materials adopt Sr(NO 3 ) 2 , Al(NO 3 ) 3 9H 2 O and La 2 o 3 , and Sr(NO 3 ) 2 , Al(NO 3 ) 3 9H 2 O and La 2 o 3 The molar ratio is 1:1:0.5; prepare a mixed solution of strontium nitrate, lanthanum nitrate and aluminum nitrate; add organic fuel and complexing agent to the mixed solution of strontium nitrate, lanthanum nitrate and aluminum nitrate, stir it with electromagnetic for 10-60min, Make a uniformly mixed solution, preferably, the time of electromagnetic stirring is 30min; the organic fuel is at le...

Embodiment 1

[0020] This embodiment provides a low-temperature preparation method of strontium lanthanum aluminate nanocomposite material, comprising the following steps:

[0021] (1) Weigh 1mol of Sr(NO 3 ) 2 and 1mol of Al(NO 3 ) 3 9H 2 O was added to No. 1 beaker, and deionized water was added and stirred to completely dissolve the contents in the beaker; weigh 0.5 mol of La with a purity of 99.99%. 2 o 3 Add to No. 2 beaker, then add excess concentrated nitric acid, wait for La 2 o 3 After completely dissolving, add ammonia water to the beaker, adjust the pH value of the solution to 4, and obtain La(NO 3 ) 3 solution. Pour the lanthanum nitrate solution in the No. 2 beaker into the No. 1 beaker, and stir the mixed solution to mix evenly to obtain the mixed solution of strontium nitrate, lanthanum nitrate and aluminum nitrate. Then weigh 4 mol of urea as fuel and 16 mol of ethylene glycol as complexing agent, add them into the mixed solution of strontium nitrate, lanthanum nit...

Embodiment 2

[0024] This embodiment provides a low-temperature preparation method of strontium lanthanum aluminate nanocomposite material, comprising the following steps:

[0025] (1) Weigh 1mol of Sr(NO 3 ) 2 and 1mol of Al(NO 3 ) 3 9H 2 O was added to No. 1 beaker, and deionized water was added and stirred to completely dissolve the contents in the beaker; weigh 0.5 mol of La with a purity of 99.99%. 2 o 3 Add to No. 2 beaker, then add excess concentrated nitric acid, wait for La 2 o 3 After completely dissolving, add ammonia water to the beaker, adjust the pH value of the solution to 4, and obtain La(NO 3 ) 3 solution. Pour the lanthanum nitrate solution in the No. 2 beaker into the No. 1 beaker, and stir the mixed solution to mix evenly to obtain the mixed solution of strontium nitrate, lanthanum nitrate and aluminum nitrate. Then weigh 1 mol of urea as fuel and 5 mol of ethylene glycol as complexing agent, add them into the mixed solution of strontium nitrate, lanthanum nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com