Enhanced coal gangue brick

A coal gangue and reinforced technology, which is applied in the field of building materials, can solve the problems of poor mechanical properties and easy frosting, and achieve the effects of reducing the phenomenon of frosting, reducing the sulfur content and improving the bond strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

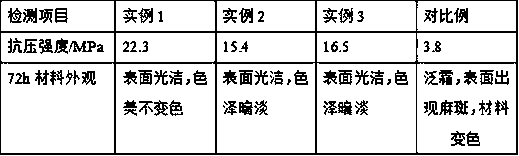

Examples

example 1

[0028] Mix the glass fiber and absolute ethanol in a beaker at a mass ratio of 1:15, and add a silane coupling agent 0.4 times the mass of the glass fiber to the beaker, move the beaker into an ultrasonic oscillator, and under the condition of a frequency of 55kHz, After ultrasonic oscillation for 20 minutes, filter to obtain a filter cake, move the filter cake into a drying oven, and dry it for 60 minutes at a temperature of 85°C to obtain a modified glass fiber; in parts by weight, weigh 85 parts of coal gangue in turn, 6 parts of clay, 15 parts of iron oxide powder, 25 parts of potassium permanganate, 12 parts of aluminum powder, 23 parts of fly ash and 8 parts of modified glass fiber, pulverize coal gangue in a pulverizer to obtain coal gangue powder, and Put clay, iron oxide powder, potassium permanganate, aluminum powder, fly ash and modified glass fiber into the ball mill, and add zirconia ball milling beads 6 times the mass of iron oxide powder, and ball mill for 30 min...

example 2

[0030] Mix the glass fiber and absolute ethanol in a beaker at a mass ratio of 1:15, and add a silane coupling agent 0.4 times the mass of the glass fiber to the beaker, move the beaker into an ultrasonic oscillator, and under the condition of a frequency of 55kHz, After ultrasonic oscillation for 20 minutes, filter to obtain a filter cake, move the filter cake into a drying oven, and dry it for 60 minutes at a temperature of 85°C to obtain a modified glass fiber; in parts by weight, weigh 85 parts of coal gangue in turn, 6 parts of clay, 15 parts of iron oxide powder, 12 parts of aluminum powder, 23 parts of fly ash and 8 parts of modified glass fiber, pulverize coal gangue in a pulverizer to obtain coal gangue powder, mix clay, iron oxide powder, aluminum Powder, fly ash and modified glass fiber were added to the ball mill, and zirconia ball milling beads with 6 times the mass of iron oxide powder were added, and the mixture was obtained by ball milling for 30 minutes. The co...

example 3

[0032]Mix the glass fiber and absolute ethanol in a beaker at a mass ratio of 1:15, and add a silane coupling agent 0.4 times the mass of the glass fiber to the beaker, move the beaker into an ultrasonic oscillator, and under the condition of a frequency of 55kHz, After ultrasonic oscillation for 20 minutes, filter to obtain a filter cake, move the filter cake into a drying oven, and dry it for 60 minutes at a temperature of 85°C to obtain a modified glass fiber; in parts by weight, weigh 85 parts of coal gangue in turn, 6 parts of clay, 25 parts of potassium permanganate, 23 parts of fly ash and 8 parts of modified glass fiber, pulverize coal gangue in a pulverizer to obtain coal gangue powder, mix clay, potassium permanganate, fly ash and Put the modified glass fiber into the ball mill, and add zirconia ball milling beads 15 times the mass of clay, and mill for 30 minutes to obtain the mixture. Mix the coal gangue powder and the mixture at a temperature of 50°C and a speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com