Oil gas recovery and exhaust gas treatment system

A technology for waste gas treatment and oil and gas, which is applied in gas treatment, combustion methods, lighting and heating equipment, etc., and can solve problems that need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

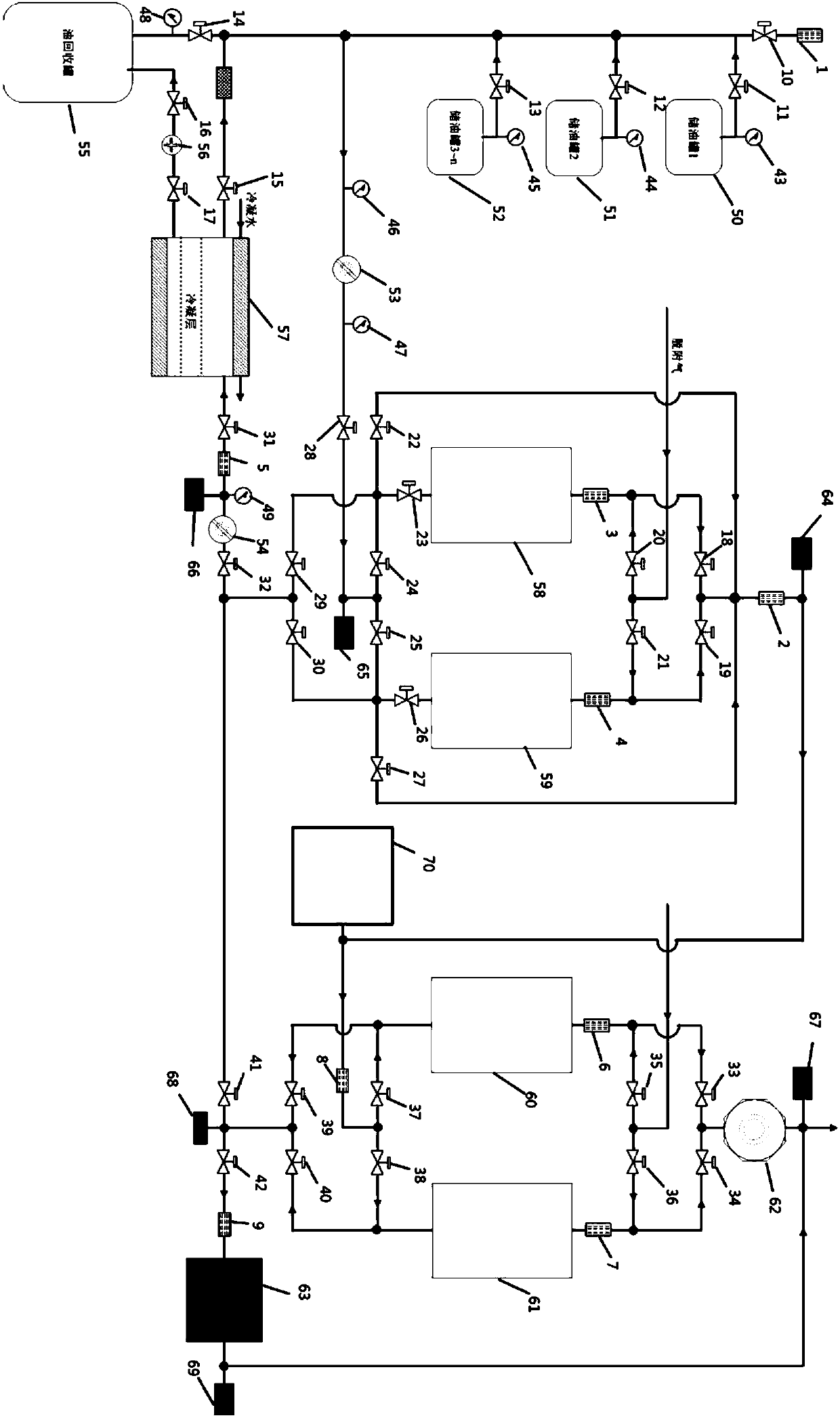

[0012] see figure 1An oil and gas recovery and waste gas treatment system of the present invention includes an oil storage tank, a flame arrester, an on-off valve, a pressure sensor, a first vacuum pump 53, a second vacuum pump 54, a recovery oil tank 55, an oil return pump 56, and a low-temperature circulating water condenser 57. , the first adsorption tank 58, the second adsorption tank 59, the third adsorption tank 60, the fourth adsorption tank 61, the adsorption fan 62, the catalytic incinerator 63, the first band FID gas chromatography 64, the second band FID gas chromatography 65, The third belt FID gas chromatography 66, the fourth belt FID gas chromatography 67, the fifth belt FID gas chromatography 68, the sixth belt FID gas chromatography 69 and the filling area 70, the oil storage tank is respectively connected with the inlet of the recovery oil tank 55 , the second band FID chromatography 65 is connected, the outlet of the said recovery oil tank 55 is connected wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap