Method for manufacturing MEMS atomic cavity of chip atomic clock

A chip atomic clock and the technology of its manufacturing method, which are applied in the field of atomic clocks, can solve the problems of rubidium vapor leakage and light transmittance, and achieve the effects of improving light transmittance, performance, and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail by the following examples. It is necessary to point out that this example is only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention. Those skilled in the art can according to the above invention Some non-essential improvements and adjustments have been made to the content. In the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

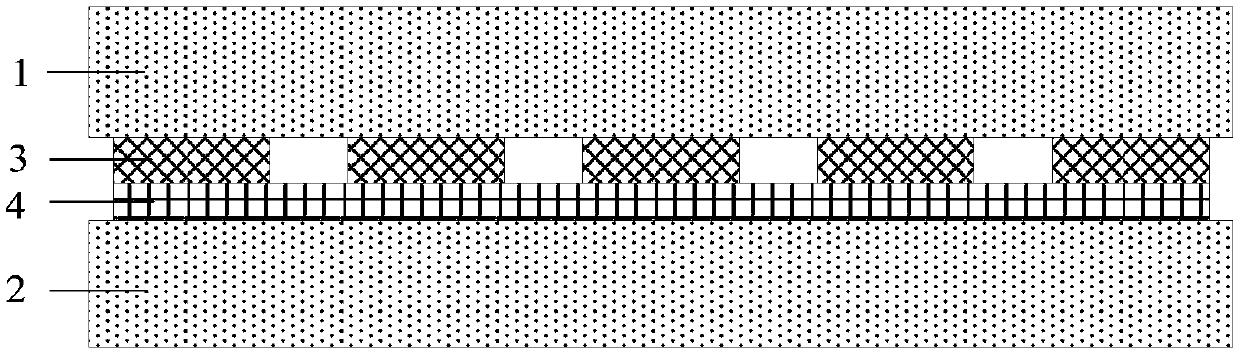

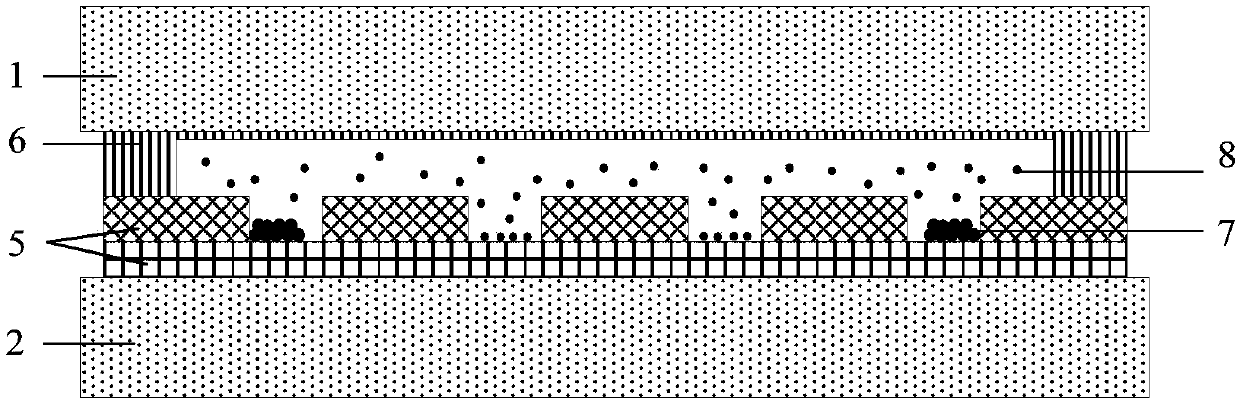

[0038] The manufacturing method of the MEMS atomic cavity of the chip atomic clock provided by the invention specifically comprises the following steps:

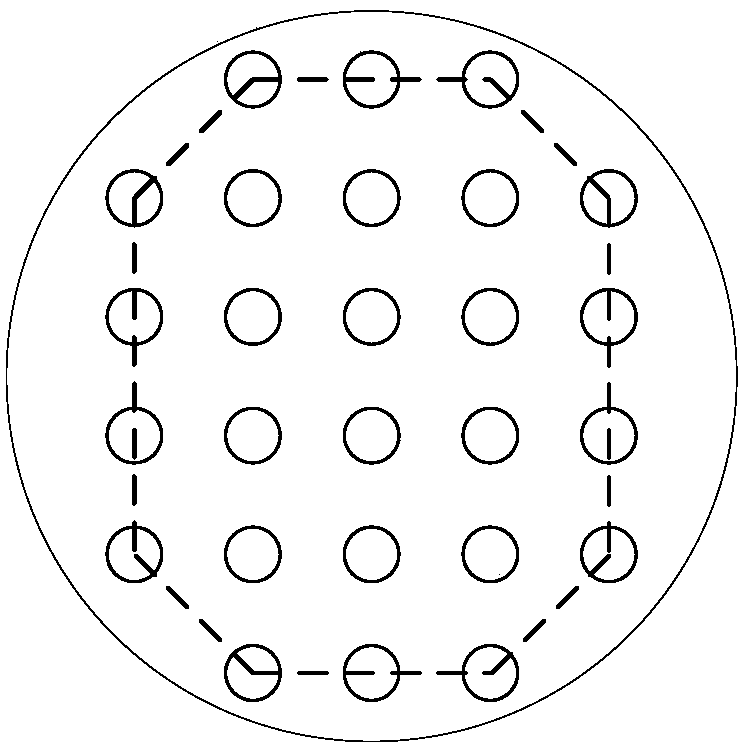

[0039] S1. Drilling and cleaning the silicon wafer: firstly, the silicon wafer is drilled, and the preferred distribution of through holes is as follows: figure 1 As shown, it is beneficial to the cutting of the MEMS atomic cavity; then the silicon wafer is cleaned to remove impuriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com