Arc extinguishing material for fuse and preparation method of arc extinguishing material

A technology of arc extinguishing materials and fuses, which is applied in the manufacture of fuses, electrical components, circuits, etc., can solve the problems of affecting the breaking effect, difficulty in controlling the uniformity of filling density, and high production costs, so as to speed up the arc extinguishing process and contribute to Extinguishing the arc and highlighting the effect of electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An arc extinguishing material for a fuse, comprising 0.3 parts of microcrystalline silicon dioxide, 1.2 parts of silicon rubber and 0.5 parts of melamine.

[0030] Method for preparing silicone rubber:

[0031] a. Carry out pretreatment to the microcrystalline silica and melamine of formula quantity, specifically, pass through respectively first

[0032] The upper sieve, and then through the lower sieve, enters the collection tray, the pore size of the upper sieve is 20μ, and the lower sieve

[0033] The aperture of the sieve is 10μ;

[0034] b. Stir the silicone rubber in the formula amount with the microcrystalline silicon dioxide and melamine treated in step a to obtain mixture A. Specifically, put the ultrasonic stirring needle into the collection tray, turn on the power, and stir for 5 minutes to obtain mixture A ;

[0035] c. Put the collection tray containing the mixture A into an oven at 100° C. for 4-4.5 hours to dry to obtain the arc extinguishing material,...

Embodiment 2

[0038] An arc extinguishing material for a fuse, comprising 0.8 parts of amorphous silicon dioxide, 1.0 parts of silicon rubber and 1.0 parts of melamine.

[0039] The preparation method of the arc extinguishing material is the same as that of Example 1.

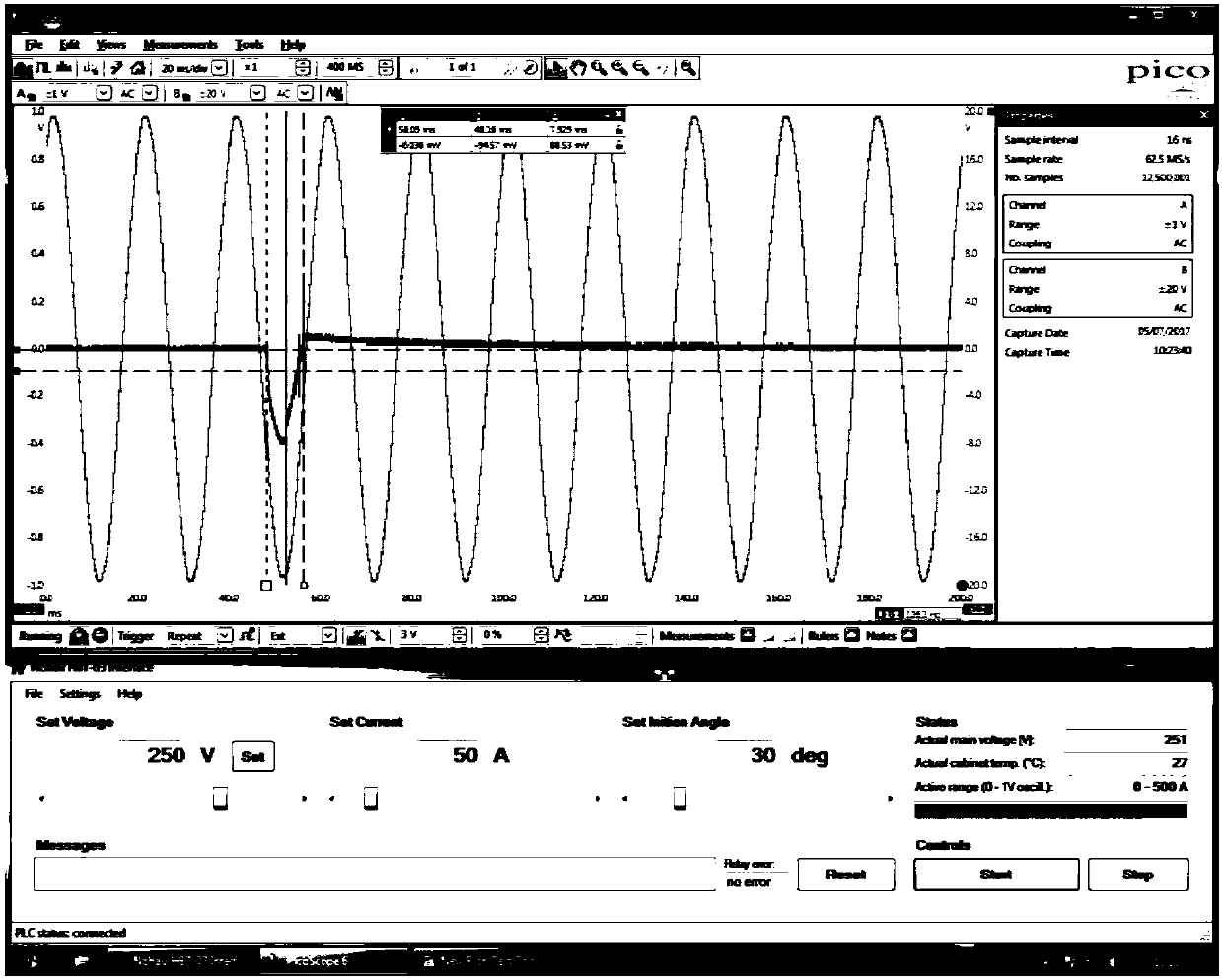

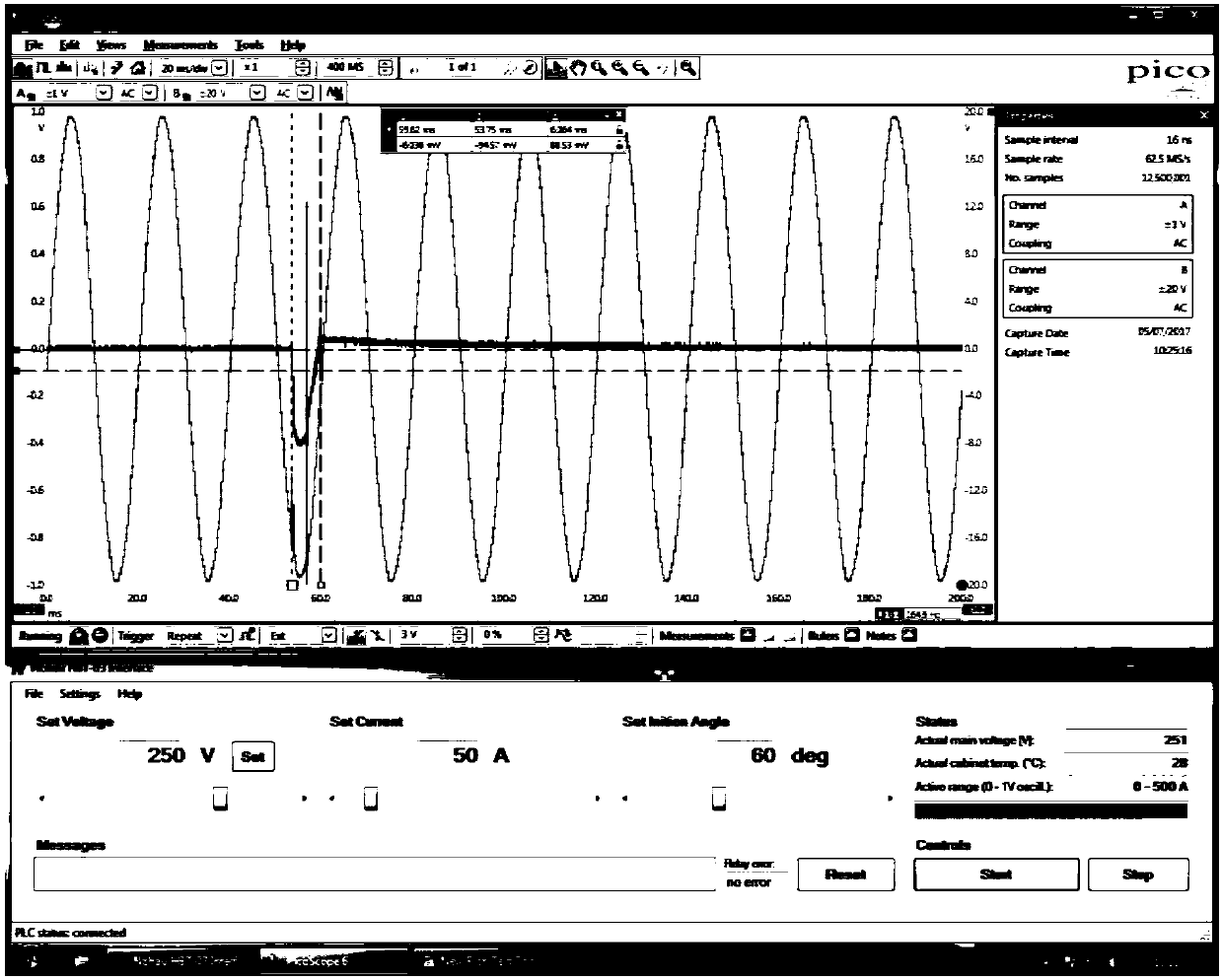

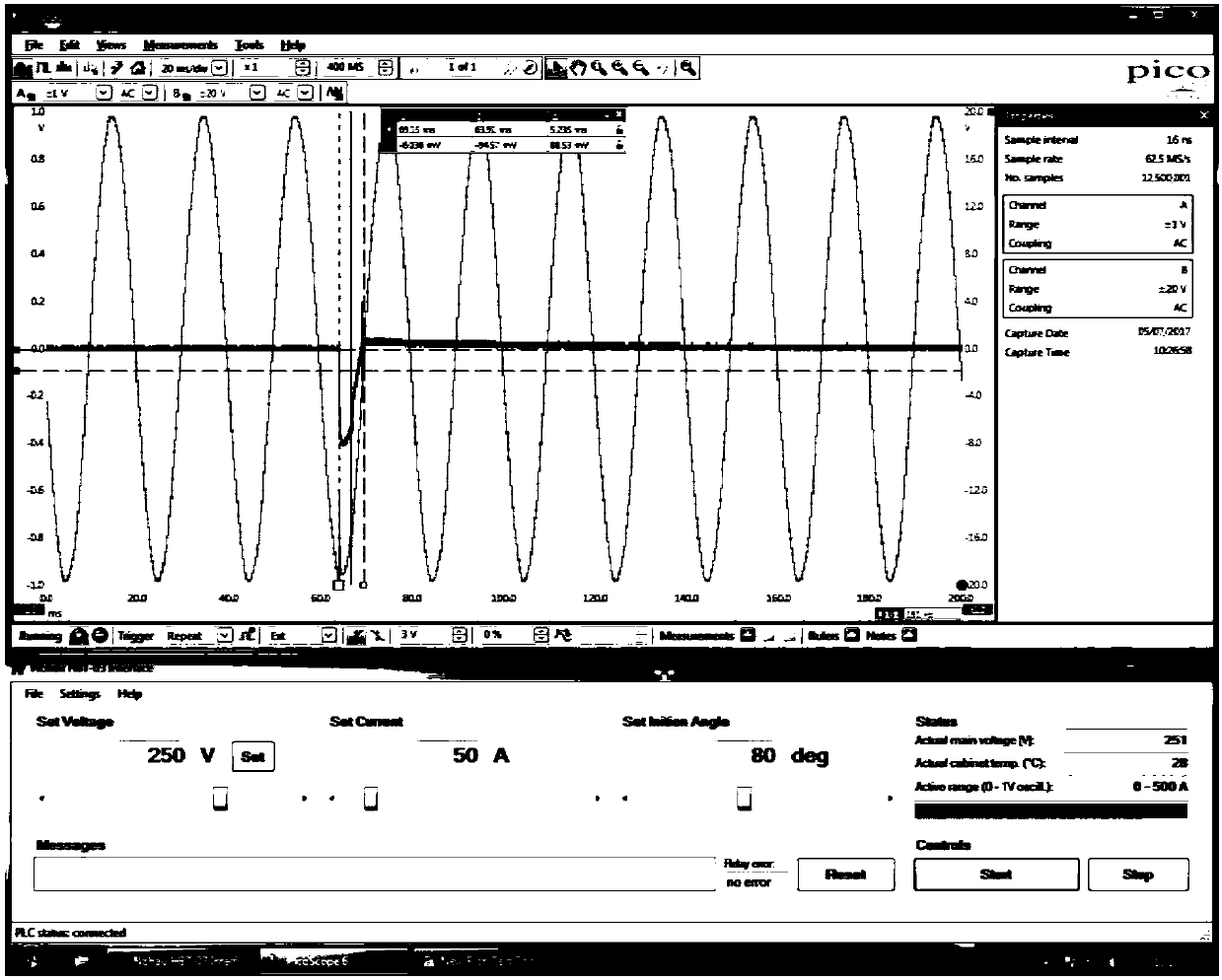

[0040] The fuse product prepared by using the arc extinguishing material of this embodiment is subjected to a 250Vac / 50A breaking capacity test. The product size is 2.8mm×6.5mm, and the amperage of the product can reach 7A or higher. After the breaking test, the product mark is clear, and the porcelain tube There is no obvious cracking, no continuous arcing phenomenon, and the cotton adhered around the fuse will not be ignited.

Embodiment 3

[0042] An arc extinguishing material for a fuse, comprising 0.6 parts of amorphous silicon dioxide, 0.2 parts of microcrystalline silicon dioxide, 1.0 parts of silicon rubber and 1.0 parts of melamine.

[0043]The preparation method of the arc extinguishing material is the same as that of Example 1.

[0044] The fuse product prepared by using the arc extinguishing material of this embodiment is subjected to a 250Vac / 50A breaking capacity test. The product size is 2.8mm×6.5mm, and the amperage of the product can reach 7A or higher. After the breaking test, the product mark is clear, and the porcelain tube There is no obvious cracking, no continuous arcing phenomenon, and the cotton adhered around the fuse will not be ignited.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com