Method for preparing lithium-sulfur battery electrode directly from hydrogen-sulfide-containing recyclate

A technology of lithium-sulfur batteries and recyclables, applied in the field of carbon-sulfur composite material preparation, can solve the problems of cumbersome operation process, unfavorable industrial production, large energy and solvent consumption, etc., and achieve the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

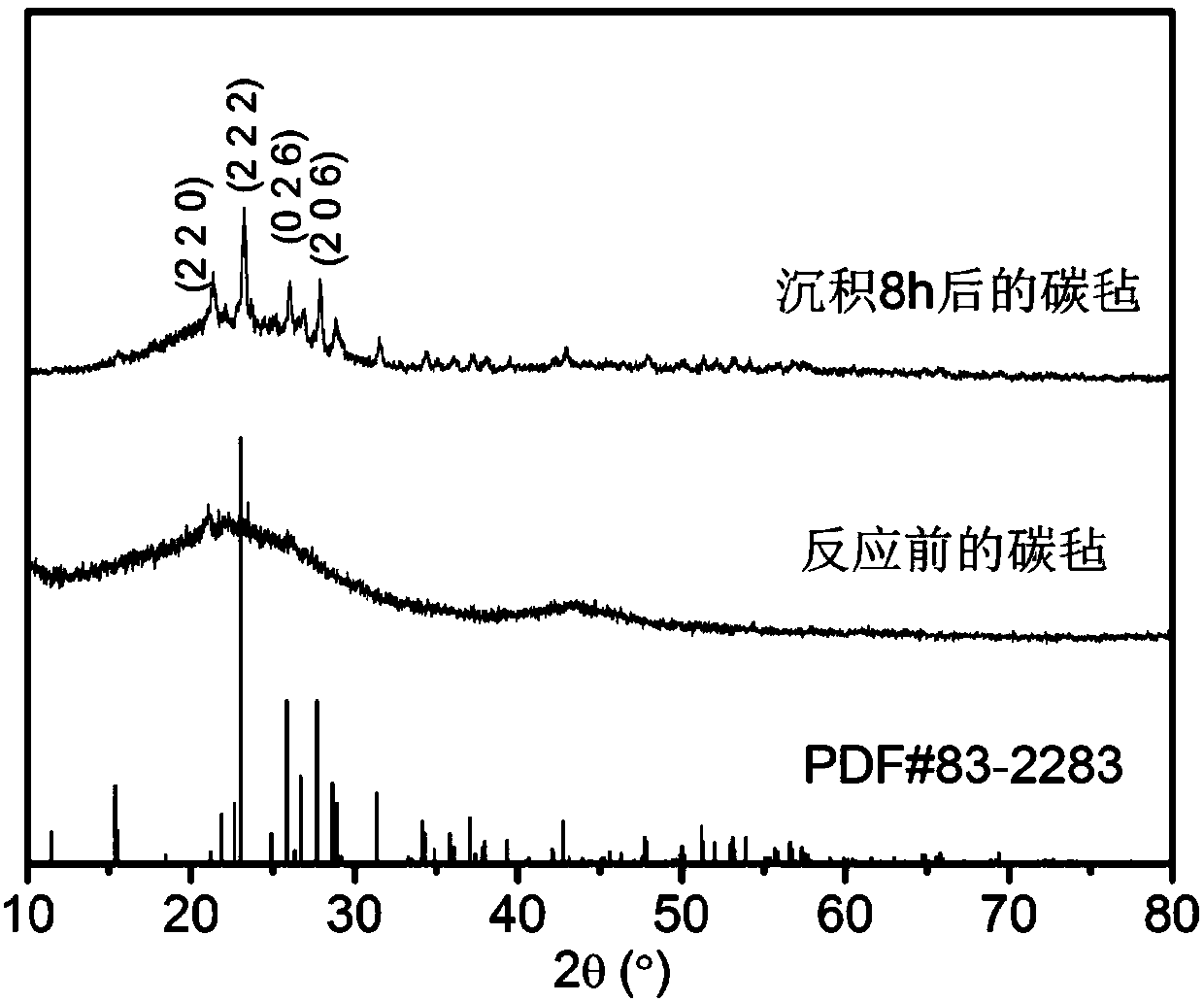

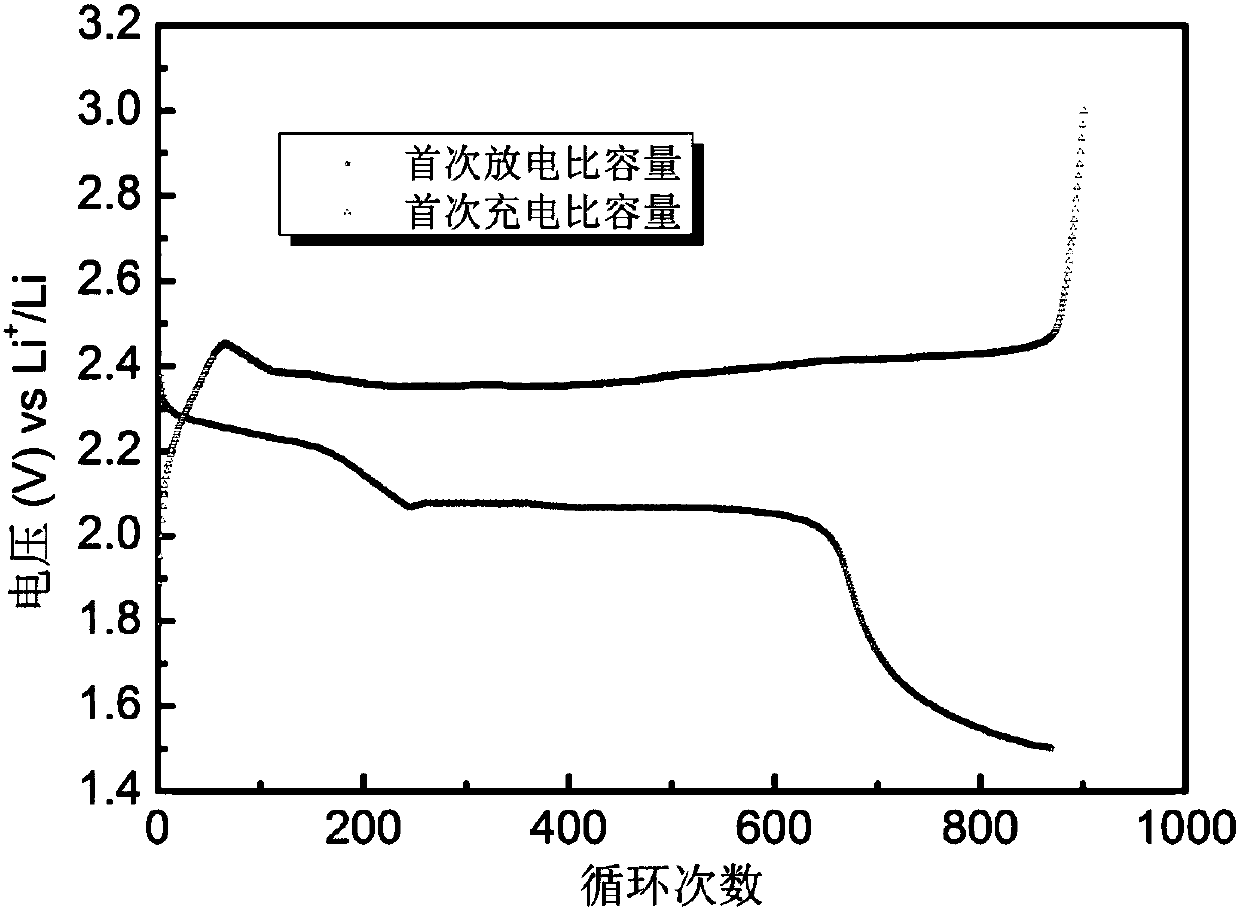

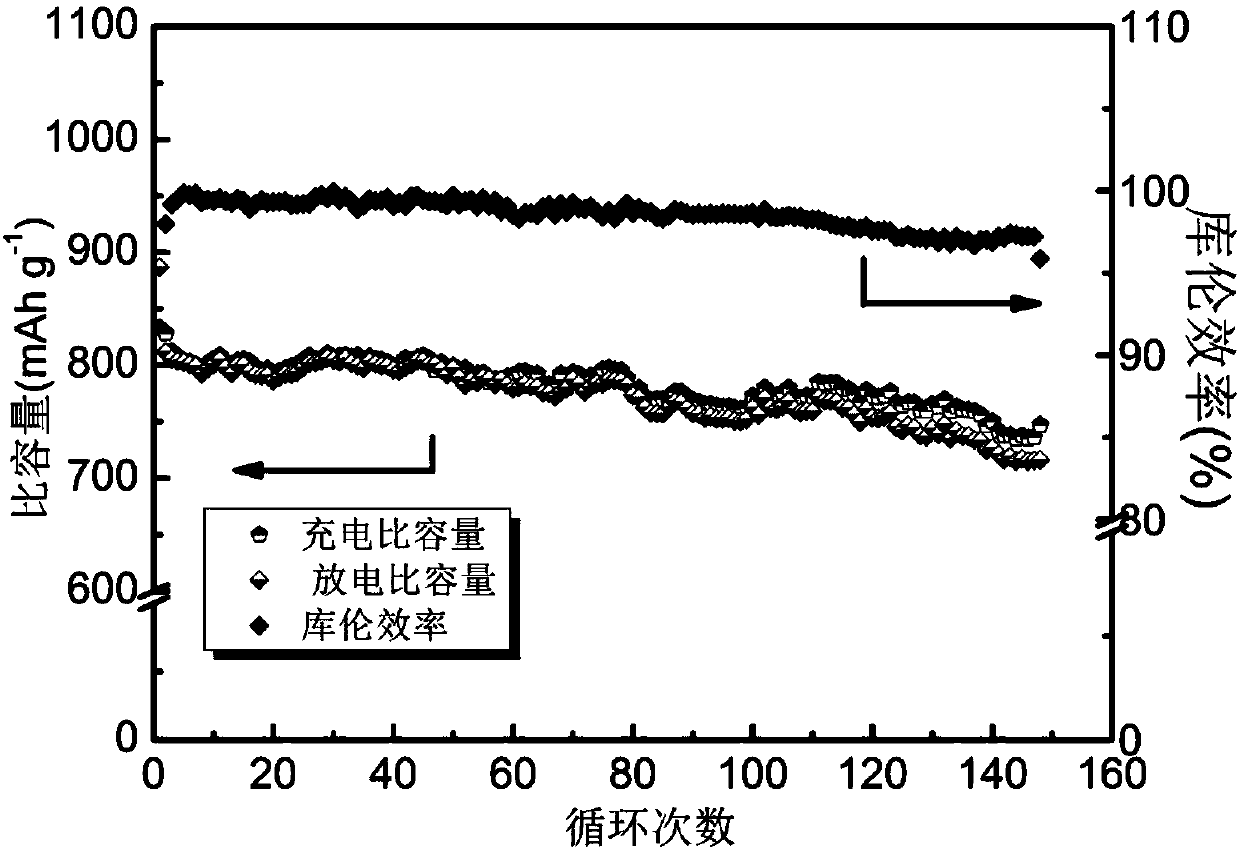

Method used

Image

Examples

Embodiment 1

[0026] (1) Inject the sulfide recovery solution into the anode chamber of the electrolytic cell, inject 0.1mol / L NaOH aqueous solution into the cathode chamber, and use conductive graphite and foamed nickel as materials for the cathode and anode respectively. The two chambers are separated by a perfluorosulfonic acid cation exchange membrane, and the sulfide recovery solution is an aqueous solution, Na 2 S is 0.35mol / L, Na 2 CO 3 is 0.5mol / L, and the pH value is 14.

[0027] (2) Pass direct current to the electrolytic cell, and the current density is controlled at 10mA / cm 2 , The electrolysis time is 16h.

[0028] (3) After the electrolysis is completed, take out the anode, wash it with distilled water, and then dry the cleaned nickel foam in a drying oven at 60°C.

[0029] (4) Cut the dried nickel foam into specific specifications as the positive electrode of the lithium-sulfur battery, use metal lithium as the negative electrode, PE / PP (celgard 2000) as the separator, 1M...

Embodiment 2

[0030] (1) Inject the sulfide recovery solution into the anode chamber of the electrolytic cell, inject 1mol / L NaOH aqueous solution into the cathode chamber, and use conductive graphite and multi-walled carbon nanotube electrodes as the cathode and anode materials respectively. The two chambers are separated by a perfluorosulfonic acid cation exchange membrane, and the sulfide recovery solution is an aqueous solution, Na 2 S is 0.25mol / L, Na 2 CO 3 is 0.15mol / L, and the pH value is 12.

[0031](2) Control the anode voltage to 0.5V vs. SCE, and the electrolysis time to 5h.

[0032] (3) After the electrolysis is completed, the anode is taken out, washed with distilled water, and then the washed multi-walled carbon nanotube electrode is placed in a 60° C. drying oven to dry.

[0033] (4) Cut the dried multi-walled carbon nanotubes into specific specifications as the positive electrode of lithium-sulfur battery, use metal lithium as the negative electrode, PE / PP (celgard 2000)...

Embodiment 3

[0035] (1) Inject the alkaline absorption solution of sulfide into the anode chamber of the electrolytic cell, inject 0.3mol / L NaOH aqueous solution into the cathode chamber, and use conductive graphite and porous carbon electrodes (such as BP2000 electrodes) for the cathode and anode materials respectively. The two chambers are separated by sodiumized perfluorosulfonic acid cation-exchange membranes, and NaHS 0.5wt% in the alkaline absorption solution of sulfide; 2 CO 3 1wt%; Na 2 S15wt%.

[0036] (2) Use cyclic voltammetry to control the potential of the anode sheet to -1.5V-3V vs. SCE electrolysis time is 0.5h.

[0037] (3) After the electrolysis was completed, the anode was taken out, washed with distilled water several times, and then the washed porous carbon electrode was dried in a 60°C drying oven.

[0038] (4) Cut the dried anode into specific specifications as the positive electrode of the lithium-sulfur battery, use metal lithium as the negative electrode, PE / PP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com