High temperature-resistant Saccharomyces cerevisiae strain and constructing method thereof

A strain of Saccharomyces cerevisiae, the technology of Saccharomyces cerevisiae, applied in the field of genetic engineering, can solve the problems of no marketed products, etc., and achieve the effects of increased cell survival rate, increased ethanol production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Simultaneous saccharification and fermentation to determine parental strains

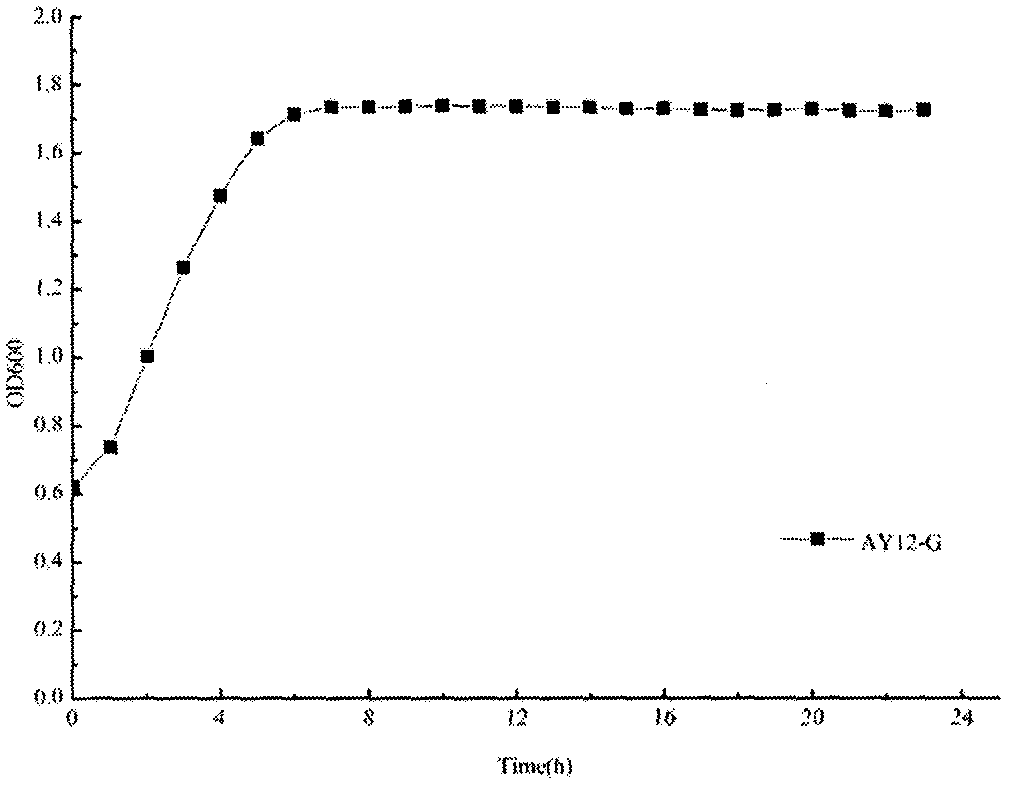

[0025] After activating Angel high temperature resistant active dry yeast with 20g / L sugar water, draw three areas on the YEPD solid plate to obtain a single colony of Saccharomyces cerevisiae. Named AY12-G. AY12-G and the strains AY12 and AY15 preserved in our laboratory were used for synchronous saccharification and fermentation of corn raw materials to select the strain with the best performance as the parent strain for subsequent experiments. Saccharomyces cerevisiae was inserted into the fermentation medium and cultured at 30°C for 12 hours, then transferred to 35°C and fermented at 160r / min. The ethanol-producing ability and reducing sugar utilization ability of each strain were tested at 33°C and 35°C respectively. At 33°C as the main fermentation temperature, the ethanol production capacity of the strain AY12-G was slightly higher than that of AY12 and AY15; at 35°C as th...

Embodiment 2

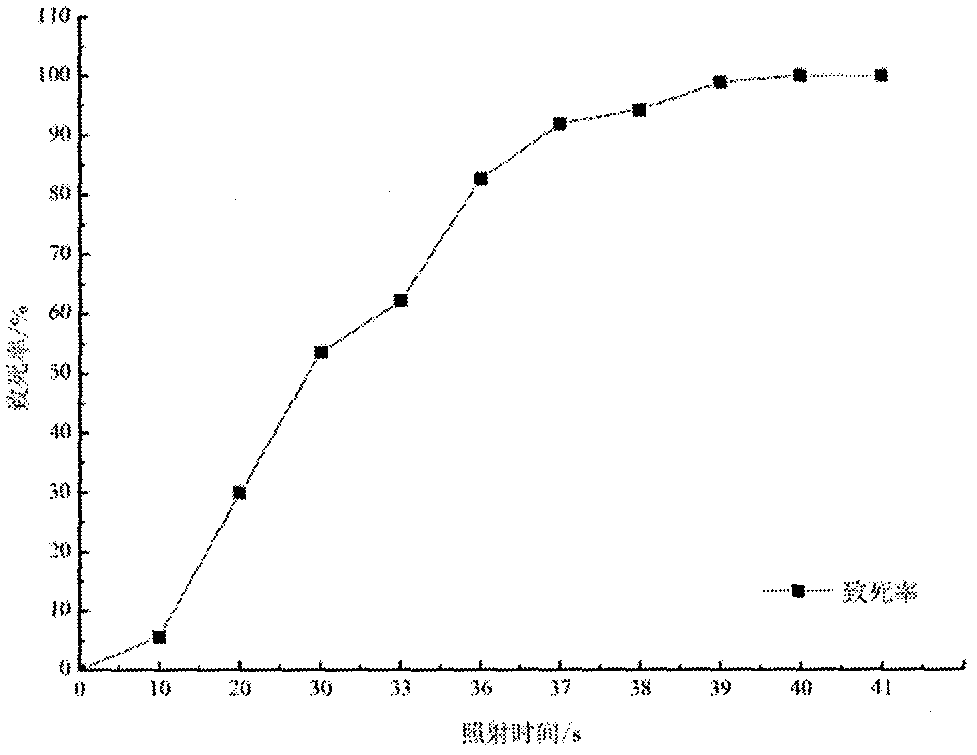

[0041] Example 2: ARTP plasma mutagenesis

[0042] Pick a ring of bacteria slime and put it into 5mL YEPD liquid medium, culture it on a shaker at 30°C and 180r / min for 12h, then put 500μL of the above bacterial solution into 5mL of fresh YEPD liquid medium, culture it on a shaker at 30°C and 180r / min for 4 -6h. Take an appropriate amount of the above bacterial solution diluted 1000 times with normal saline, take 10 μL of the diluted bacterial solution and spot on the ARTP mutagenesis slide for plasma mutagenesis treatment, the treatment time is 20s, 30s, 40s, 50s, 60s, 70s respectively. After the mutagenesis treatment is completed, place the treated slides in a 2mL centrifuge tube with 1mL sterile saline, shake vigorously with a vortex shaker for 3min, take the shaken bacteria solution and spread it on a YEPD plate, and place it at 30°C cultured in a constant temperature incubator. The first round of lethal curve is drawn, and the time period of mortality ≥ 60% to 100% is t...

Embodiment 3

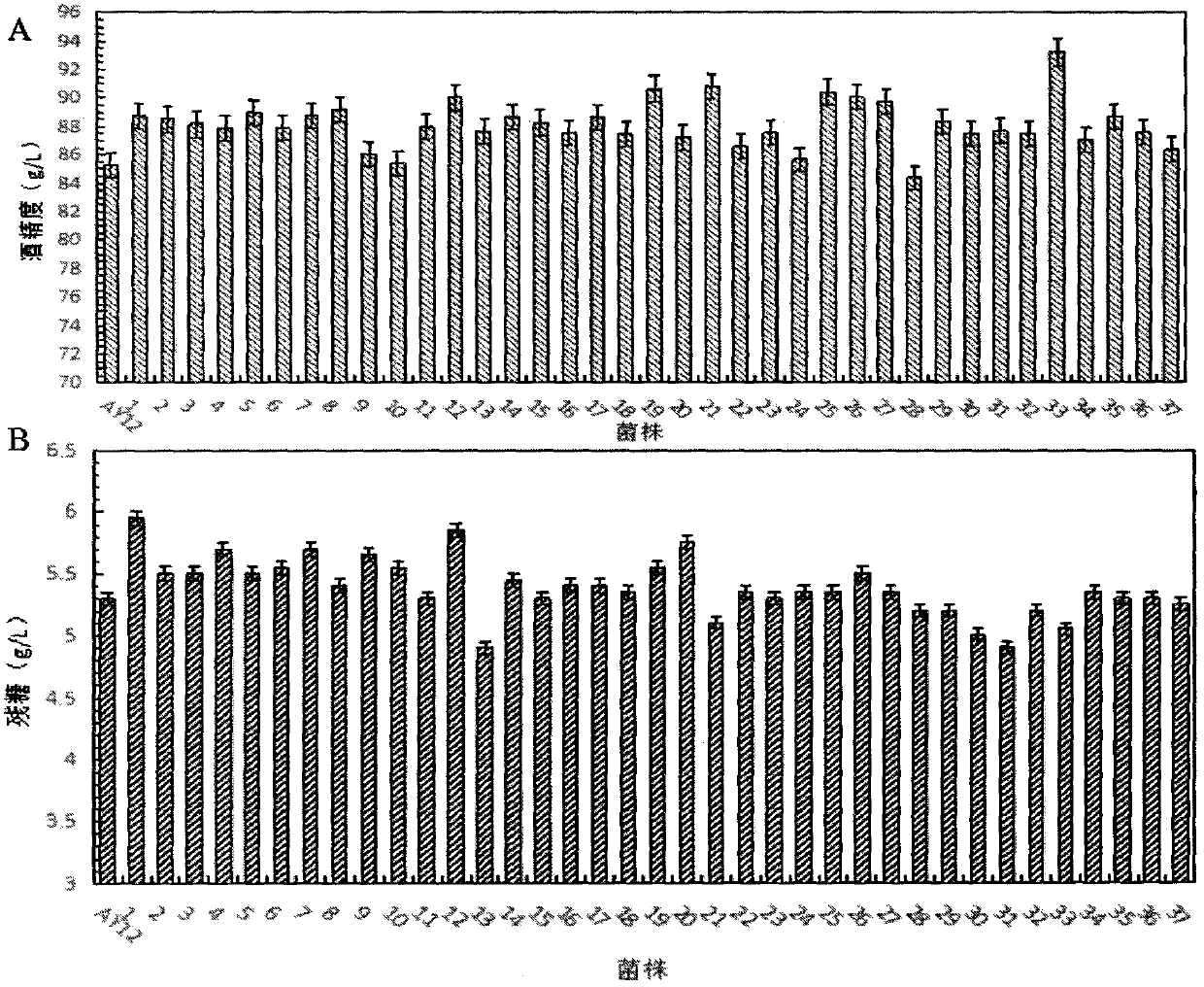

[0044] Example 3: Genome Rearrangement

[0045] Genome rearrangement was performed on 150 strains screened after ARTP ion mutagenesis to further improve the high temperature resistance of the strains. The obtained 150 positive mutant cell populations were all inoculated into fresh YEPD liquid medium, cultured to the logarithmic phase at 30°C and 180 r / min, and the cells were collected by centrifugation. The collected bacteria were washed with sterile water, and then the washed bacteria sludge was inserted into the YPK pre-sporulation medium, cultured at 28°C and 180r / min for 12 hours, and the bacteria were collected by centrifugation. After washing the collected bacteria three times with sterile water, they were inserted into high-efficiency liquid sporulation medium, and cultured at 28° C. and 180 r / min for 5 days. Bacteria were collected by centrifugation, followed by spore purification.

[0046] First, resuspend the spore-forming bacteria of the mutant population in softe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com