Manufacturing method of ceramic PCB and manufactured PCB

A manufacturing method and technology of ceramics, which are applied in the manufacture of printed circuits, coatings, electrical components, etc., can solve the problems of limited types of ceramic materials, high processing temperature, complicated procedures, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

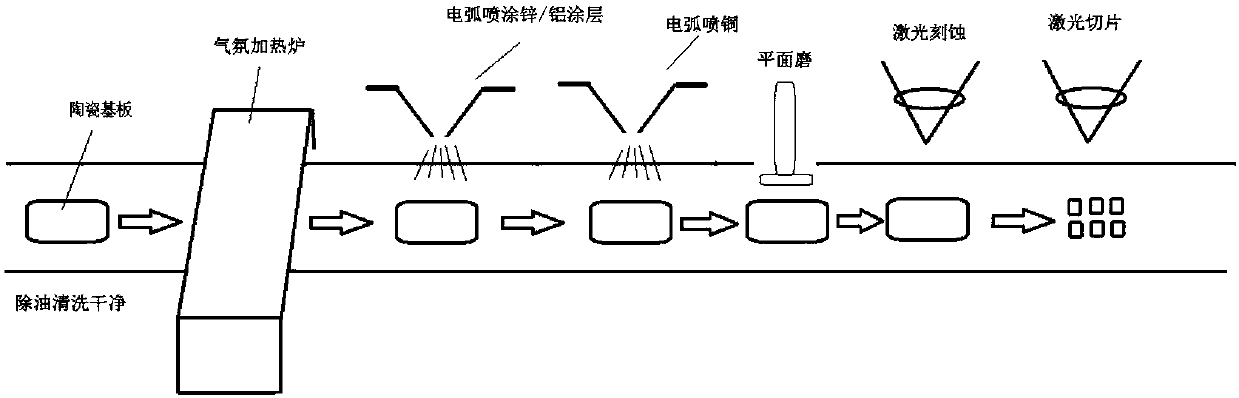

[0029] The process flow of a kind of alumina ceramic PCB provided by this embodiment is as follows: figure 1 As shown, it includes the following steps:

[0030] S1. Put the 0.4mm thick alumina ceramic substrate into an ultrasonic cleaning machine for rinsing, cleaning and drying to complete the degreasing process of the ceramic substrate;

[0031] S2. Send the dried ceramic substrate into a common atmosphere heating furnace and heat it to 350°C, and keep it warm for 10-15 minutes to ensure that the overall temperature of the alumina ceramic substrate tends to be consistent, so as to improve the activation performance of the surface of the ceramic substrate. Among them, the atmosphere heating The furnace is a mixed atmosphere of carbon monoxide 80% + 20% nitrogen (use one or more mixed gases such as hydrogen, carbon monoxide, nitrogen, argon to provide a reducing atmosphere), and the atmosphere heating furnace can be an ordinary industrial electric furnace;

[0032] S3. Use an...

Embodiment 2

[0037] This embodiment takes the method of manufacturing a silicon nitride ceramic PCB with good insulation as an example, which includes the following steps:

[0038] S1. Put the 0.1mm thick silicon nitride ceramic substrate into an ultrasonic cleaning machine for rinsing, cleaning and drying to complete the cleaning process of the silicon nitride ceramic substrate;

[0039] S2. Send the dried high-stability silicon nitride ceramics into an ordinary industrial electric furnace and heat it to 360° C., and keep it warm for 5-8 minutes. Among them, the atmosphere heating furnace is a mixed atmosphere of argon 20%+80% nitrogen (volume ratio );

[0040] S3. Use an industrial conveyor belt to send the silicon nitride ceramic substrate to the position of the next process, and use an infrared thermometer to test the surface temperature of the silicon nitride ceramic substrate. When the temperature of the silicon nitride ceramic surface is above 340°C, enter the spraying process If i...

Embodiment 3

[0045] This embodiment takes the method of preparing an aluminum nitride ceramic PCB with good thermal conductivity as an example to illustrate, which includes the following steps:

[0046] S1. Put the 0.2mm aluminum nitride ceramic substrate into an ultrasonic cleaning machine for rinsing, cleaning and drying to complete the stain cleaning process of aluminum nitride ceramics;

[0047] S2. Send the dried aluminum nitride substrate with good thermal conductivity into an ordinary industrial electric furnace and heat it to 395°C, and keep it warm for 7-10 minutes. );

[0048] S3. Use an industrial conveyor belt to send the aluminum nitride ceramic substrate to the position of the spraying process, and use an infrared thermometer to measure the surface temperature of the aluminum nitride ceramic substrate online. When the surface temperature of the aluminum nitride ceramic substrate is above 345°C, enter the spraying process If it is lower than 345°C, it will return to the ordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com