High-active ZnIn2S4/TiO2 Z system catalyst material and preparation method thereof

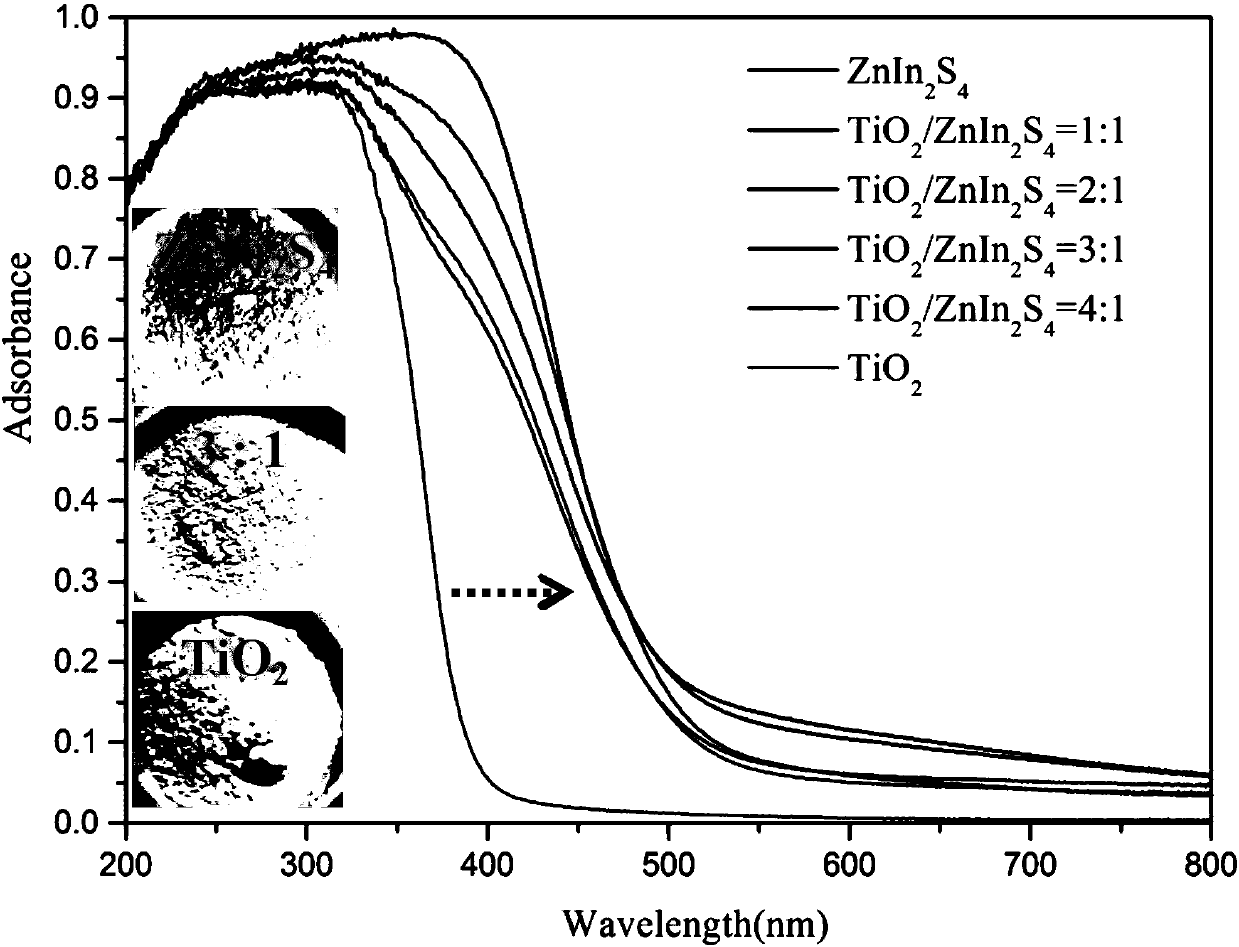

A technology of znin2s4 and catalyst, which is applied in the field of photocatalytic material research, can solve the problems of weakened oxidation ability and reduction ability of semiconductor materials, reduced photocatalytic activity of visible light, and influence on photocatalytic activity of materials, and achieves excellent catalytic reduction CO2 performance and high practicality Value and application prospects, the effect of expanding the range of light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

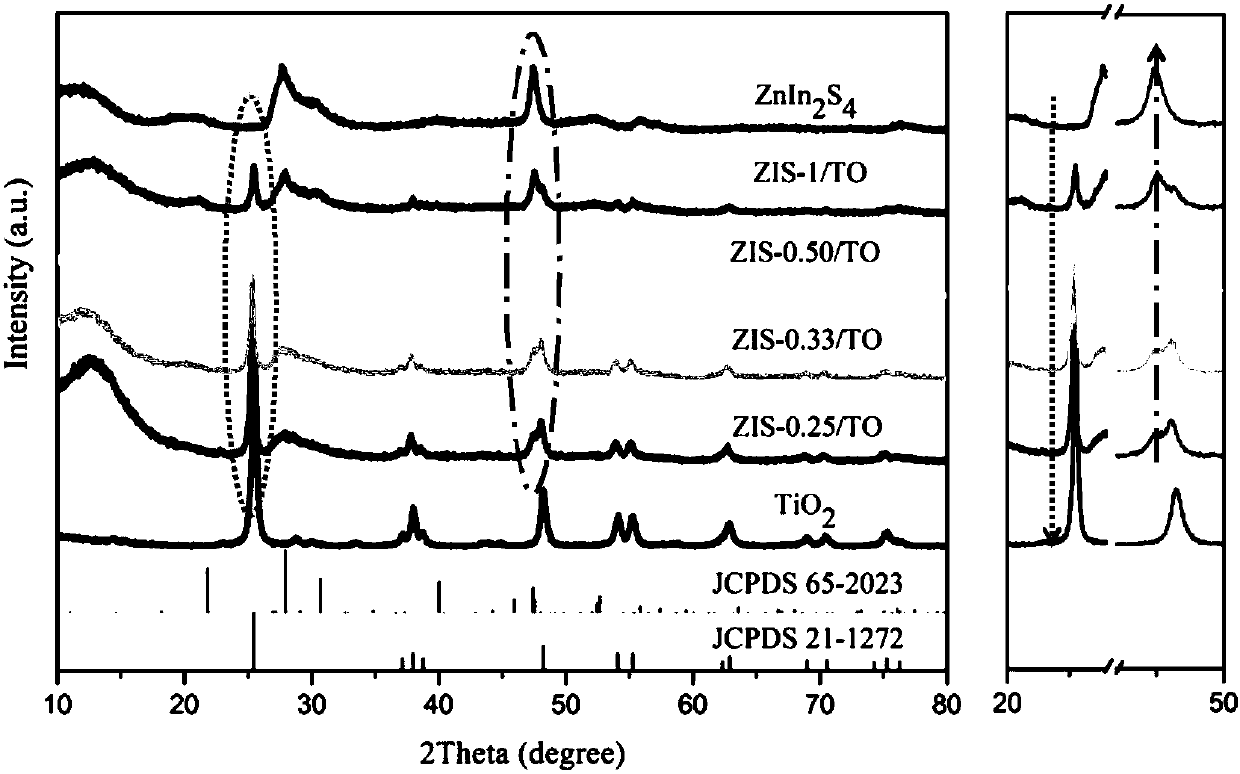

Embodiment 1

[0019] Weigh 0.043g zinc chloride (ZnCl 2 ), 0.018g indium chloride (InCl 3 ) and 0.1g of thioacetamide (TAA) were ultrasonically dissolved in 80mL of ethylene glycol and kept stirring at room temperature for 0.5 hours; then weighed 0.1g of TiO 2 Nanoribbon powder was added to the above solution, ultrasonically dispersed for 0.5 hours, and then stirred for 1 hour; then the formed solution was transferred to a 100mL polytetrafluoroethylene-lined autoclave, and solvothermal at 120°C for 2 hours; After the product was centrifuged, washed and separated, it was dried in an oven for 8 hours to obtain the corresponding ZnIn 2 S 4 loaded TiO 2 Nanobelt composite photocatalyst, labeled ZIS-0.25 / TO(ZnIn 2 S 4 / TiO 2 mol ratio 0.25:1).

Embodiment 2

[0021] Weigh 0.057g zinc chloride (ZnCl 2 ), 0.024g indium chloride (InCl 3 ) and 0.14g of thioacetamide (TAA) were ultrasonically dissolved in 80mL of ethylene glycol, and stirred continuously at room temperature for 0.5 hours; then weighed 0.1g of TiO 2 Add nanoribbon powder to the above solution, ultrasonically disperse for 0.5 hours, and then stir for 1 hour; then transfer the formed solution to a 25ml polytetrafluoroethylene-lined autoclave, and heat it at 120°C for 2 hours; After the product was centrifuged, washed and separated, it was dried in an oven for 8 hours to obtain the corresponding ZnIn 2 S 4 loaded TiO 2 Nanobelt composite photocatalyst, labeled ZIS-0.33 / TO(ZnIn 2 S 4 / TiO 2 mol ratio 0.33:1).

Embodiment 3

[0023] Weigh 0.086g zinc chloride (ZnCl 2 ), 0.036g indium chloride (InCl3 ) and 0.2g of thioacetamide (TAA) were ultrasonically dissolved in 80mL of ethylene glycol, and stirred continuously at room temperature for 0.5 hours; then weighed 0.1g of TiO 2 Add nanoribbon powder to the above solution, ultrasonically disperse for 0.5 hours, and then stir for 1 hour; then transfer the formed solution to a 25ml polytetrafluoroethylene-lined autoclave, and heat it at 120°C for 2 hours; After the product was centrifuged, washed and separated, it was dried in an oven for 8 hours to obtain the corresponding ZnIn 2 S 4 loaded TiO 2 Nanoribbon composite photocatalyst, labeled ZIS-0.50 / TO(ZnIn 2 S 4 / TiO 2 mol ratio 0.50:1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com