Styrene-free epoxy vinyl ester resin synthesis process

A technology for synthesizing epoxy vinyl esters and resins, applied in the field of polymer materials, can solve the problems of difficult reaction control, high reaction temperature, side reactions, etc., and achieve the effects of uniform reaction, lower reaction temperature, and prolonged reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

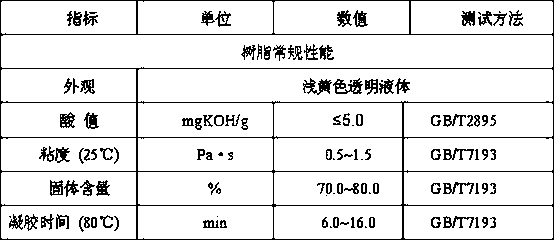

Image

Examples

Embodiment 1

[0039] After dissolving 0.60 g of catalyst aluminum chloride with ethanol, add it to 105 g of hydroxyethyl methacrylate, stir evenly, and set aside. 450g of bisphenol A epoxy resin E51, 4.0g of catalyst trimethylamine, and 0.15g of tert-butylhydroquinone were put into the reactor. In the case of nitrogen gas, gradually raise the temperature to 80°C, keep the temperature and stir, add dropwise the hydroxyethyl methacrylate dissolved in the catalyst, after 0.5 hours, add 60g of methacrylic acid, fully stir, and gradually raise the temperature to 90°C React for 1.5 hours, and the acid value is less than 10 mgKOH / g; cool down to below 60°C and add 360 g of trimethylolpropane triacrylate, and finally cool to room temperature, filter to obtain a light yellow viscous liquid.

Embodiment 2

[0041] Dissolve 1.0 g of catalyst ferric chloride in methanol, add it to 95 g of hydroxypropyl acrylate, stir evenly, and set aside. In the reactor, drop into 360g bisphenol A type epoxy resin E44, catalyst pyridine 15g, tert-butyl catechol 0.20g. In the case of nitrogen gas, gradually raise the temperature to 50°C, keep the temperature and stir, add dropwise the hydroxypropyl acrylate dissolved in the catalyst, and drop it in 0.5 hours, then add 70g of acrylic acid, stir well, gradually raise the temperature to 80°C and react for 1.5 hours, The acid value is less than 10mgKOH / g; cool down to below 60°C and add 400g of tripropylene glycol diacrylate, and finally cool to room temperature and filter to obtain a light yellow viscous liquid.

Embodiment 3

[0043] Dissolve 0.7 g of catalyst aluminum chloride in methanol, add it to 100 g of hydroxyethyl acrylate, stir evenly, and set aside. 400g of bisphenol A type epoxy resin E51, 10g of catalyst methyl sulfide, and 0.30g of hydroquinone were put into the reactor. In the case of nitrogen gas, gradually raise the temperature to 60°C, keep the temperature and stir, add dropwise the hydroxyethyl acrylate dissolved in the catalyst, and drop it in 0.5 hours, then add 65g of fumaric acid, stir well, and gradually raise the temperature to 70°C React for 1.5 hours, and the acid value is less than 10mgKOH / g; cool down to below 60°C and add 450g of neopentyl glycol diacrylate, and finally cool to room temperature, and filter to obtain a light yellow viscous liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com