A kind of titanium silicon molecular sieve and its synthesis method and application and a kind of method of cyclic ketone oxidation

A technology of titanium-silicon molecular sieve and synthesis method, which is applied in the direction of molecular sieve catalysts, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., and can solve problems such as long crystallization time of titanium-silicon molecular sieves, unsatisfactory effects, and weak crystal guiding ability , to achieve the effects of easy industrial application, increased selectivity, and favorable diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

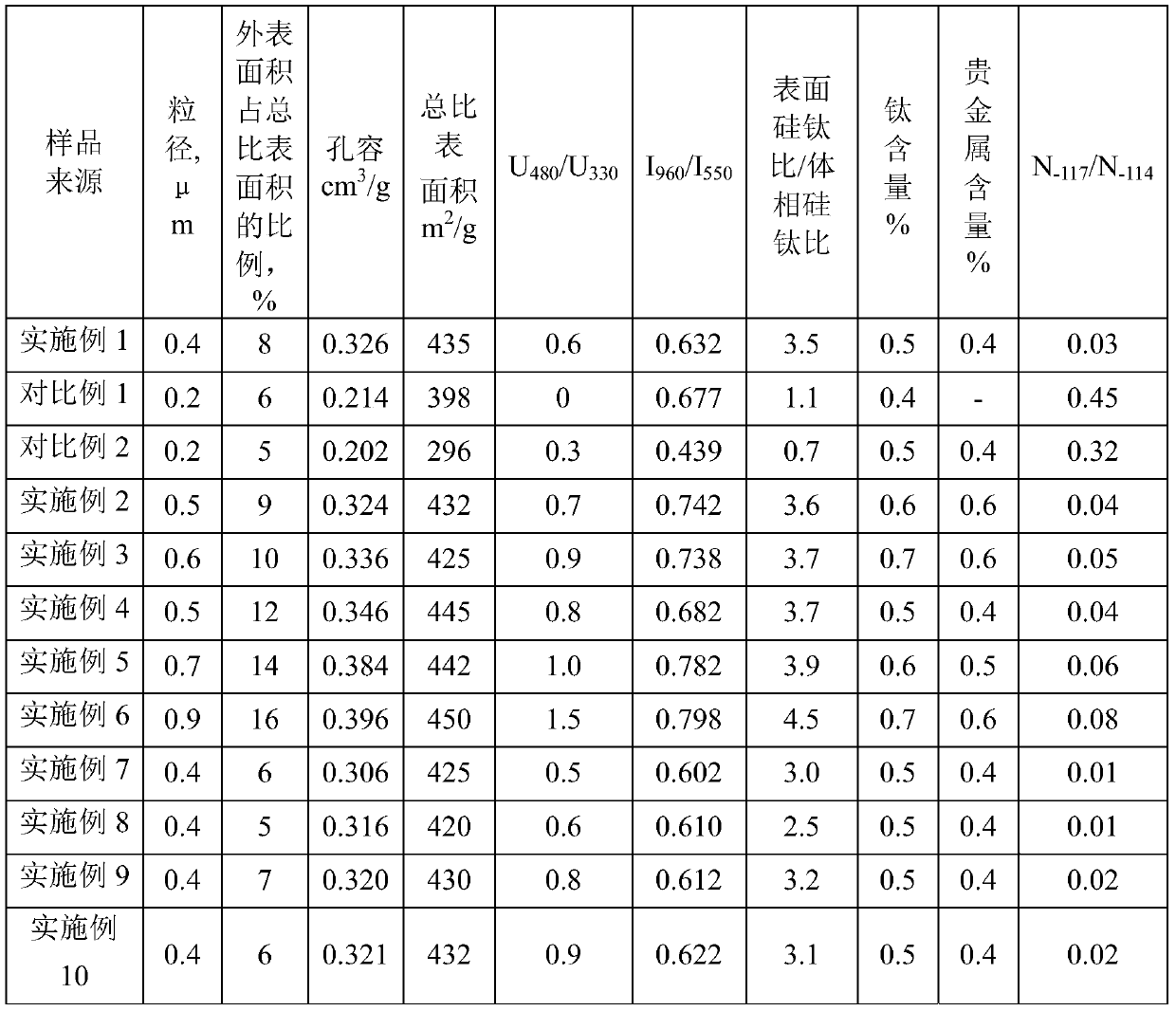

[0031]In the present invention, as long as the titanium-silicon molecular sieve has the aforementioned characteristics, the purpose of the present invention can be achieved, and its synthesis method can be various, as long as the titanium-silicon molecular sieve with the aforementioned characteristics can be synthesized. For the present invention, the titanium-silicon molecular sieve is preferably Silicon molecular sieves are synthesized as follows, the method comprising:

[0032] (1) mixing and contacting a precious metal source, an ammonia source, and optionally water to obtain a first mixture;

[0033] (2) In the presence of a templating agent, mixing the titanium source, the first mixture, and optionally water to obtain a second mixture;

[0034] (3) mixing the second mixture, an inorganic silicon source, and optionally water to obtain a third mixture;

[0035] (4) The third mixture is subjected to hydrothermal crystallization, and titanium-silicon molecular sieves are re...

Embodiment approach

[0042] According to a preferred embodiment of the present invention, the preferred stage (1) and stage (3) meet one or both of the following conditions:

[0043] Condition 1: the temperature of stage (1) is lower than the temperature of stage (3), preferably, the temperature of stage (1) is 10-50°C lower than the temperature of stage (3), preferably 20-40°C lower;

[0044] Condition 2: the time of stage (1) is less than the time of stage (3), preferably, the time of stage (1) is 5-24 hours shorter than the time of stage (3), preferably 6-12 hours shorter.

[0045] According to a preferred embodiment of the present invention, the temperature in stage (2) is lowered to not higher than 50°C, preferably 30-50°C, and the residence time is at least 1 hour, preferably 1-5h.

[0046] According to the method of the present invention, the heating rate and cooling rate for adjusting the temperature to the temperature of each stage can be selected according to the type of the reactor used...

Embodiment 1

[0094] (1) Mixing and contacting noble metal source palladium chloride and ammonia water (concentration is 20% by weight) to obtain a mixture; noble metal source: ammonia source (weight ratio)=2:20, solute content is 1% by weight, and the conditions for mixing and contacting include: 30°C, normal pressure, 4h;

[0095] (2) The mixture is then mixed with tetrabutyl titanate and tetrapropyl ammonium hydroxide;

[0096] (3) Then add silica gel, mix and carry out hydrothermal crystallization; silicon source: titanium source: precious metal source: templating agent: water (mol) = 100:2:1:15:1000;

[0097] Hydrothermal crystallization: go through the first stage at 140°C for 6 hours in a sealed reactor, then cool the mixture down to 30°C and experience the second stage for 2 hours, then continue to go through the third stage at a temperature of 170°C in a sealed reactor 12h (among them, the temperature rise rate from room temperature to the first stage temperature is 2°C / min, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com