Preparation method for super-macroporous silicate molecular sieve

A technology of porous silicate and molecular sieve, which is applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of cumbersome steps and molecular sieve application limitations, and achieve good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

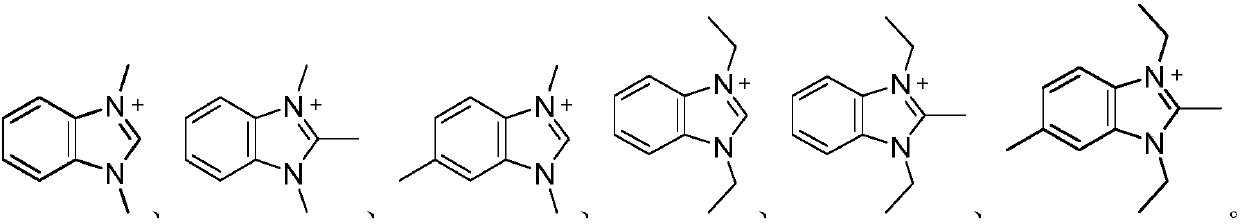

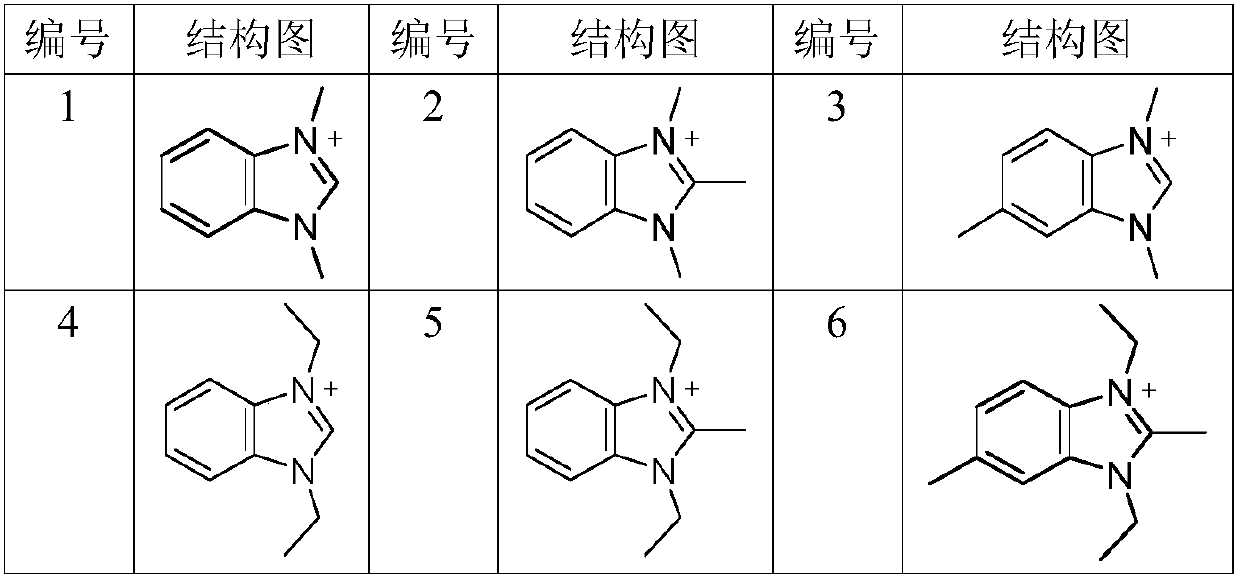

[0027] Embodiment 1: Taking the template agent 1 in Table 1 as an example, the synthesis process of the template agent is illustrated.

[0028] 39.648g of benzimidazole was dissolved in 750mL of tetrahydrofuran solution, and then 14.4g of sodium hydroxide was added, and the reaction was carried out under reflux for one day. After cooling down to room temperature, 60 mL of iodomethane was added. The system was reacted under stirring for two days, the reaction mixture was filtered with suction, and the filter residue was washed three times with acetone. The product was then dried with a yield of 97%. The product was subjected to liquid NMR (D 2 O) and electrospray mass spectrometry characterization, confirmed as the target compound.

[0029] The obtained product was dissolved in 100 mL of deionized water, and column exchange was performed through 717 strong basic anion exchange resin to obtain an aqueous solution of the template agent in the form of hydroxide. Weigh an appro...

Embodiment 2

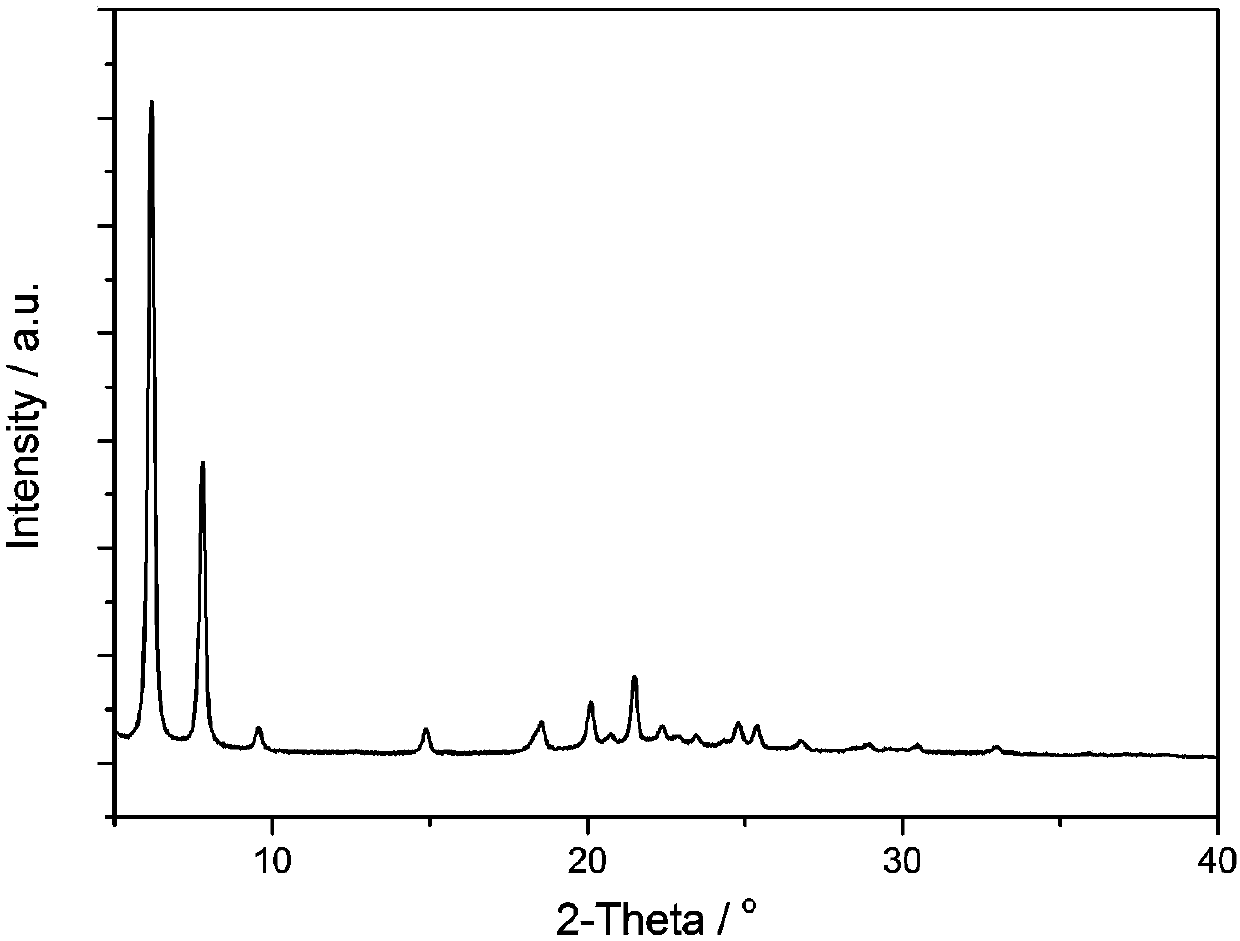

[0031] Embodiment 2: according to molar ratio 1SiO 2 :0.5ROH:0.5HF:5H 2The ratio of O to prepare the gel synthesized by molecular sieves, the general steps are as follows: Weigh an appropriate amount of template agent 1 solution after exchange, add 5mmol (1.042g) of tetraethyl orthosilicate to it, stir at room temperature for about two hours to make orthosilicate Dissolve ethyl acetate completely, then add a designed amount of hydrofluoric acid solution, stir evenly, place the mixed gel under an infrared lamp or in an oven at 80°C, and remove excess solvent to a theoretical weight. The final reaction gel was transferred to a 15mL stainless steel reaction kettle with polytetrafluoroethylene lining, and reacted at 150°C for 30 days under sealed conditions. The product was washed twice with water and twice with ethanol, and dried to obtain the product. Take an appropriate amount of sample and calcinate it in a muffle furnace at 550°C for 2 hours in an air atmosphere to remove th...

Embodiment 3

[0032] Embodiment 3: according to molar ratio 1SiO 2 :0.5ROH:0.5HF:5H 2 Ratio of O Prepare molecular sieve-synthesized gels using the hydroxide form of 1-methyl-3-benzyl imidazolium salt similar to the templates in Table 1 It is a template agent, synthesized according to the method of Example 2, and the X-ray powder diffraction of the obtained product is identified as an amorphous substance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com