Anti-mold anti-wearing repairing agent and preparation method thereof

A repairing agent and anti-mildew technology, which is applied in the field of repairing agents, can solve the problems of mildew resistance, discoloration, and easy oxidation, etc., and achieve the effect of strong anti-oxidation performance, good anti-mildew performance, and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

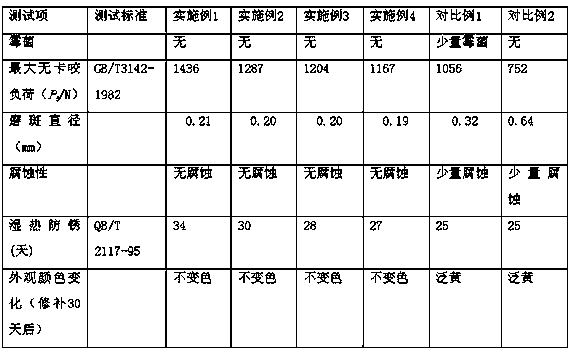

Examples

Embodiment 1

[0018] An anti-mildew and anti-wear repair agent, the repair agent is prepared from the following raw materials in parts by weight: 80 parts of epoxy resin, 4 parts of silane coupling agent, 9 parts of mica powder, 11 parts of graphene oxide, nano magnetic particles 8 parts, 7 parts of nano-ceramic powder, 12 parts of molybdenum disulfide, 10 parts of nano-silver particles, 3 parts of titanate coupling agent, 22 parts of isopropanol, 5 parts of polyvinylpyrrolidone, 5 parts of ethylene-acrylic acid copolymer, 6 parts of glyceryl tristearate, 4 parts of 2-(4-thiazolyl)benzimidazole, 6 parts of 8-hydroxyquinoline copper, 3-6 parts of copper sulfate, and 5 parts of adsorption film corrosion inhibitor.

[0019] Preferably, the silane coupling agent is glycidoxypropyltrimethoxysilane.

[0020] Preferably, the titanate coupling agent is isopropyl tris(dioctyl phosphate acyloxy) titanate.

[0021] Preferably, the adsorption film corrosion inhibitor is C15 chain aliphatic amine.

[...

Embodiment 2

[0027] An anti-mildew and anti-wear repair agent, the repair agent is prepared from the following raw materials in parts by weight: 60 parts of epoxy resin, 3 parts of silane coupling agent, 7 parts of mica powder, 8 parts of graphene oxide, nano-magnetic particles 6 parts, 5 parts of nano-ceramic powder, 9 parts of molybdenum disulfide, 7 parts of nano-silver particles, 2 parts of titanate coupling agent, 15 parts of isopropanol, 3 parts of polyvinylpyrrolidone, 4 parts of ethylene-acrylic acid copolymer, 5 parts of glyceryl tristearate, 2 parts of 2-(4-thiazolyl)benzimidazole, 4 parts of 8-hydroxyquinoline copper, 3 parts of copper sulfate, and 3 parts of adsorption film corrosion inhibitor.

[0028] Preferably, the silane coupling agent is vinyltrimethoxysilane.

[0029] Preferably, the titanate coupling agent is isopropyl dioleate (dioctyl phosphate acyloxy) titanate.

[0030] Preferably, the adsorption film corrosion inhibitor is C16 chain aliphatic amine.

[0031] The ...

Embodiment 3

[0036] An anti-mildew and anti-wear repair agent, the repair agent is prepared from the following raw materials in parts by weight: 100 parts of epoxy resin, 6 parts of silane coupling agent, 12 parts of mica powder, 15 parts of graphene oxide, nano magnetic particles 10 parts, 10 parts of nano-ceramic powder, 14 parts of molybdenum disulfide, 12 parts of nano-silver particles, 5 parts of titanate coupling agent, 30 parts of isopropanol, 6 parts of polyvinylpyrrolidone, 7 parts of ethylene-acrylic acid copolymer, 8 parts of glyceryl tristearate, 5 parts of 2-(4-thiazolyl)benzimidazole, 8 parts of 8-hydroxyquinoline copper, 6 parts of copper sulfate, and 7 parts of adsorption film corrosion inhibitor.

[0037] Preferably, the silane coupling agent is methacryloxytrimethoxysilane.

[0038] Preferably, the titanate coupling agent is monoalkoxy unsaturated fatty acid titanate.

[0039] Preferably, the adsorption film corrosion inhibitor is C17 chain aliphatic amine.

[0040] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com