Ultra-low temperature metal organic ligand doped amino acid composite material and preparation method thereof

A technology of metal-organic and composite materials, applied in the field of new functional materials, can solve problems such as poor selective adsorption capacity and difficult crystal size control, and achieve the effects of improving stability, improving selective adsorption capacity, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

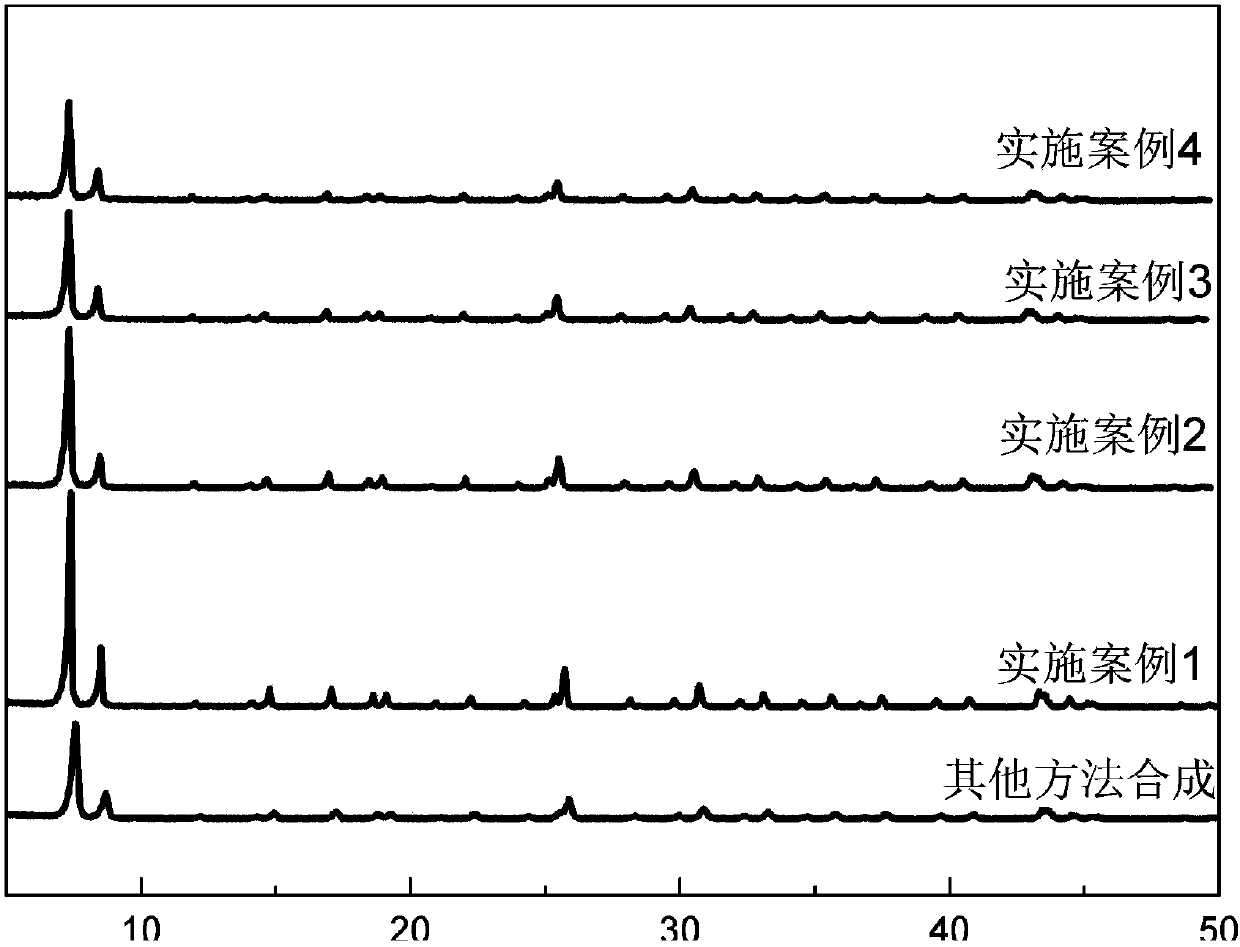

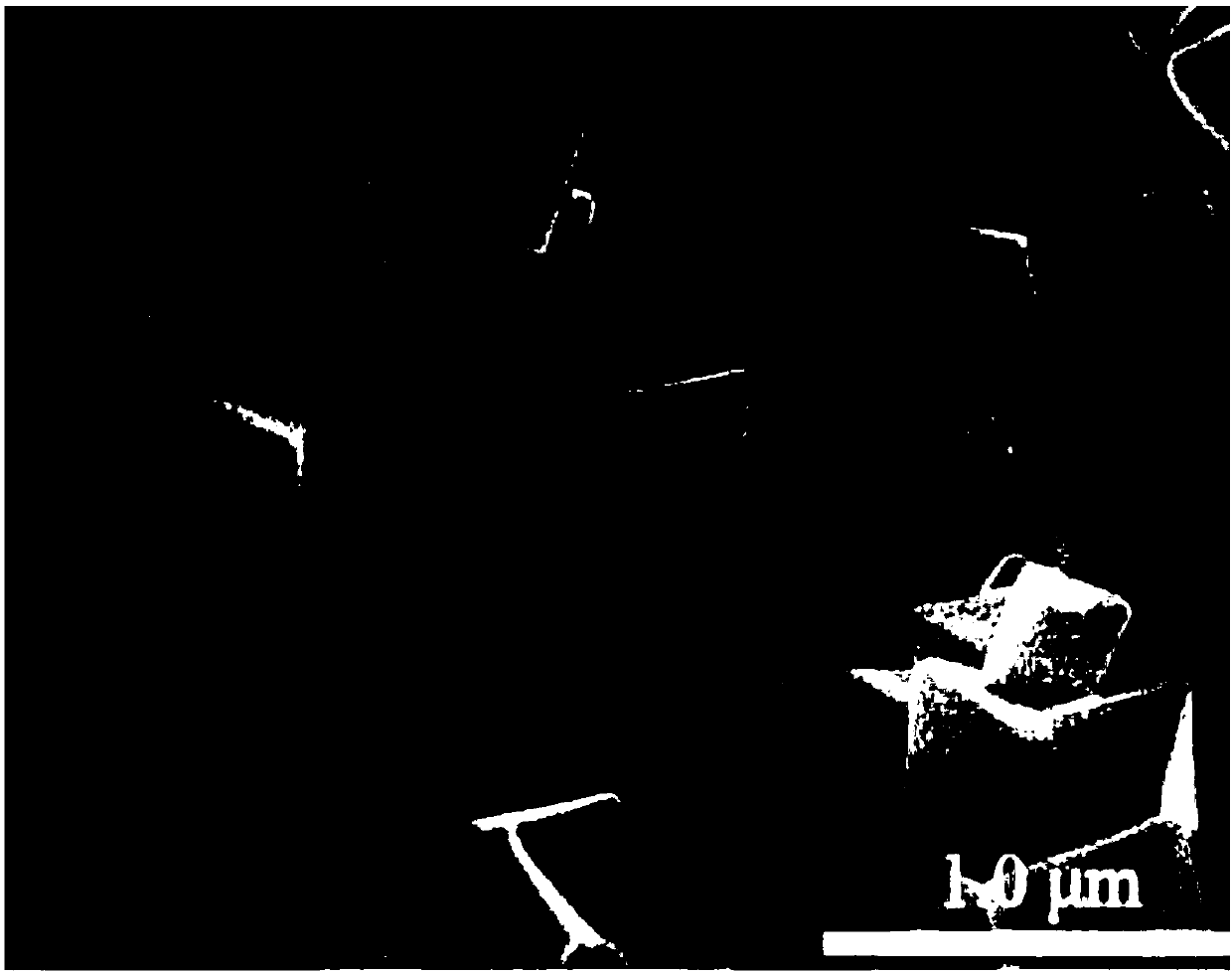

Embodiment 1

[0034] A method for preparing an ultra-low temperature metal organic framework material, comprising the steps of:

[0035] (1) Preparation of zirconium chloride solution: put 40mL N,N-dimethylformamide DMF solvent in a 100ml beaker, weigh 1.1660g (5mmol) zirconium chloride ZrCl 4 Slowly add to the flask, place on a magnetic stirrer and mechanically stir at a speed of 300rmp / min to fully dissolve the zirconium chloride, and record it as solution A;

[0036] (2) Preparation of terephthalic acid solution: weigh 0.8310g (5mmol) terephthalic acid H 2 Dissolve BDC in 30mL of N,N-dimethylformamide (DMF) solvent in a 50ml beaker, mechanically stir at a speed of 400rmp / min under the action of a magnetic stirrer for 10min to fully dissolve it, and record it as solution B;

[0037] (3) Preparation of metal organic framework materials: fully pre-freeze solutions A and B first, adjust the temperature to -35°C in an ultra-low temperature constant temperature tank, mechanically stir at a sp...

Embodiment 2

[0039] A method for preparing an ultra-low temperature metal-organic ligand-doped amino acid composite material, comprising the steps of:

[0040](1) Preparation of zirconium chloride solution: put 50mL N,N-dimethylformamide DMF solvent in a 100ml beaker, weigh 0.9328g (4mmol) zirconium chloride ZrCl 4 Slowly add to the flask, place it on a magnetic stirrer and mechanically stir at a speed of 350rmp / min to fully dissolve the zirconium chloride, and record it as solution A;

[0041] (2) Preparation of terephthalic acid solution: weigh 0.6648g (4mmol) terephthalic acid H 2 Dissolve BDC in 20mL N,N-dimethylformamide DMF solvent in a 50ml beaker, mechanically stir at a speed of 300rmp / min under the action of a magnetic stirrer for 8min to fully dissolve, and record it as solution B;

[0042] (3) Preparation of proline solution: Weigh 10mmol of proline and dissolve it in 20mL of N,N-dimethylformamide (DMF) solvent, slowly add 1.8mL of hydrochloric acid solution dropwise, and mecha...

Embodiment 3

[0045] A method for preparing an ultra-low temperature metal-organic ligand-doped amino acid composite material, comprising the steps of:

[0046] (1) Preparation of zirconium chloride solution: put 50mL N,N-dimethylformamide DMF solvent in a 100ml beaker, weigh 1.1660g (5mmol) zirconium chloride ZrCl 4 Slowly add to the flask, place it on a magnetic stirrer and mechanically stir at a speed of 400rmp / min to fully dissolve the zirconium chloride, and record it as solution A;

[0047] (2) Preparation of terephthalic acid solution: weigh 0.8310g (5mmol) terephthalic acid H 2 Dissolve BDC in 30mL N,N-dimethylformamide DMF solvent in a 50ml beaker, mechanically stir at a speed of 500rmp / min under the action of a magnetic stirrer for 10min to fully dissolve, and record it as solution B;

[0048] (3) Preparation of phenylalanine solution: Weigh 10mmol of phenylalanine and dissolve it in 20mL of N,N-dimethylformamide DMF solvent, slowly add 2.0mL of hydrochloric acid solution dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com