Nano heavy metal wastewater ion adsorption microspheres and preparation method thereof

An ion adsorption, heavy metal technology, applied in the directions of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of poor adsorption effect, high price, poor desorption ability, etc. The effect of low cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

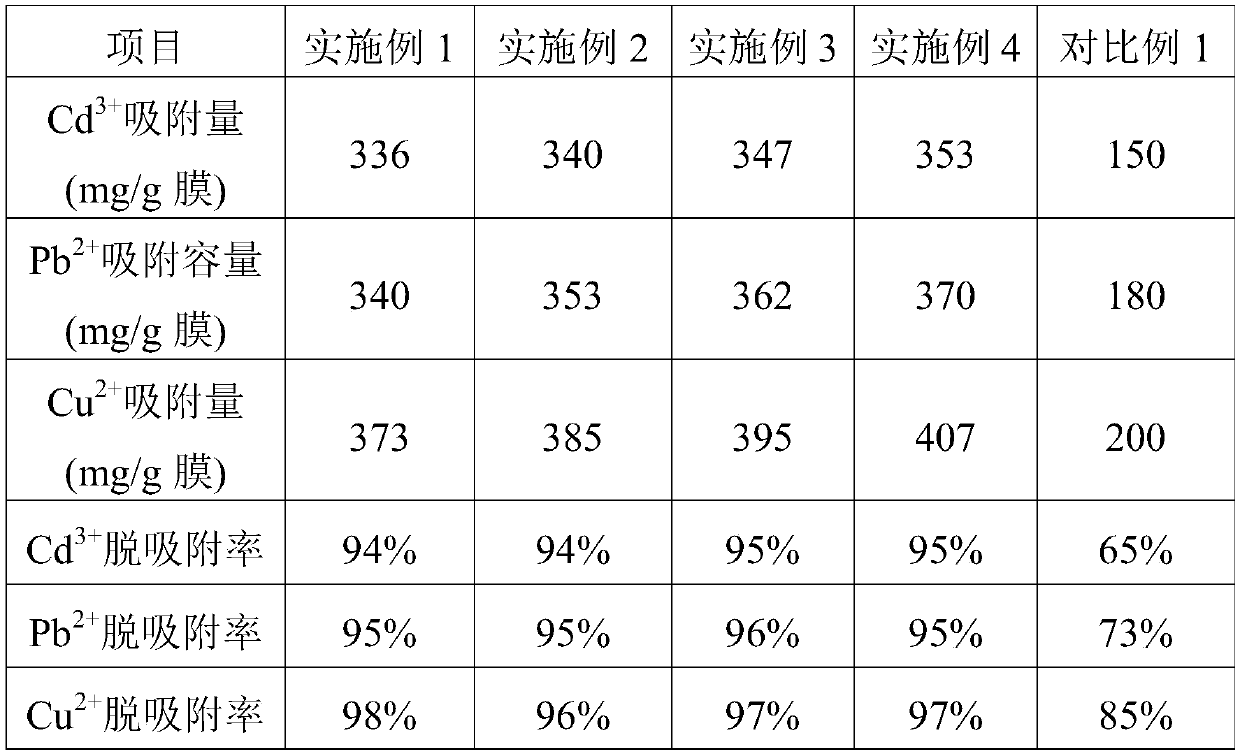

Embodiment 1

[0023] A method for preparing nano heavy metal wastewater ion adsorption microspheres, comprising the steps of:

[0024] 1) Preparation of porous graphene microspheres: Mix 100 g of graphene oxide with 1000 g of deionized water evenly, disperse ultrasonically for 15 minutes, then add 20 g of polystyrene microspheres, so that polystyrene microspheres are evenly dispersed in graphene oxide , then add 100g of glucose, mix well, then carry out electrostatic spraying, wet collection, then add it to dimethyl sulfoxide and soak for 5 hours, and then dry it for 6 hours under wet conditions to obtain porous nano Graphene microspheres;

[0025] 2) Surface modification of porous graphene microspheres: Disperse 90 g of porous graphene microspheres prepared in step 1) in 300 g of ethanol, add 1,3,5-tris[3-(trimethoxysilyl)propane base]-1,3,5-triazine-2,4,6(1H,3H,5H)-trione 30g, stirred at 40°C for 3 hours, then added 30g of ethyl chloride, kept stirring for 4 hours, Then centrifuged, was...

Embodiment 2

[0029] A method for preparing nano heavy metal wastewater ion adsorption microspheres, comprising the steps of:

[0030] 1) Preparation of porous graphene microspheres: Mix 100 g of graphene oxide and 1000 g of deionized water evenly, disperse ultrasonically for 17 minutes, and then add 40 g of polymethyl methacrylate microspheres to make the polymethyl methacrylate microspheres uniform Disperse in graphene oxide, then add 100g of glucose, mix well, then carry out electrostatic spraying, wet collection, then add it into N,N-dimethylformamide and soak for 5.5 hours, and then under wet conditions, use Near-point drying method for 7 hours to obtain porous nano-graphene microspheres;

[0031] 2) Surface modification of porous graphene microspheres: Disperse 120 g of porous graphene microspheres prepared in step 1) in 360 g of ethanol, add 1,3,5-tris[3-(trimethoxysilyl)propane base]-1,3,5-triazine-2,4,6(1H,3H,5H)-trione 30g, stirred at 45°C for 4 hours, then added bromopropane, ke...

Embodiment 3

[0035] A method for preparing nano heavy metal wastewater ion adsorption microspheres, comprising the steps of:

[0036] 1) Preparation of porous graphene microspheres: Mix 100 g of graphene oxide and 1000 g of deionized water evenly, disperse ultrasonically for 18 minutes, then add 60 g of polybutylacrylate microspheres, so that polybutylacrylate microspheres are evenly dispersed in graphite oxide Then add 100g of glucose, mix evenly, then carry out electrostatic spraying, wet collection, then add it into N-methylpyrrolidone and soak for 5.8 hours, and then use the near-point drying method under wet conditions for 9 hours, Obtain porous nano-graphene microspheres;

[0037] 2) Surface modification of porous graphene microspheres: Disperse 140 g of porous graphene microspheres prepared in step 1) in 400 g of ethanol, add 1,3,5-tris[3-(trimethoxysilyl)propane base]-1,3,5-triazine-2,4,6(1H,3H,5H)-trione 30g, stirred at 47°C for 5 hours, then added bromoethane 50g, kept stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com