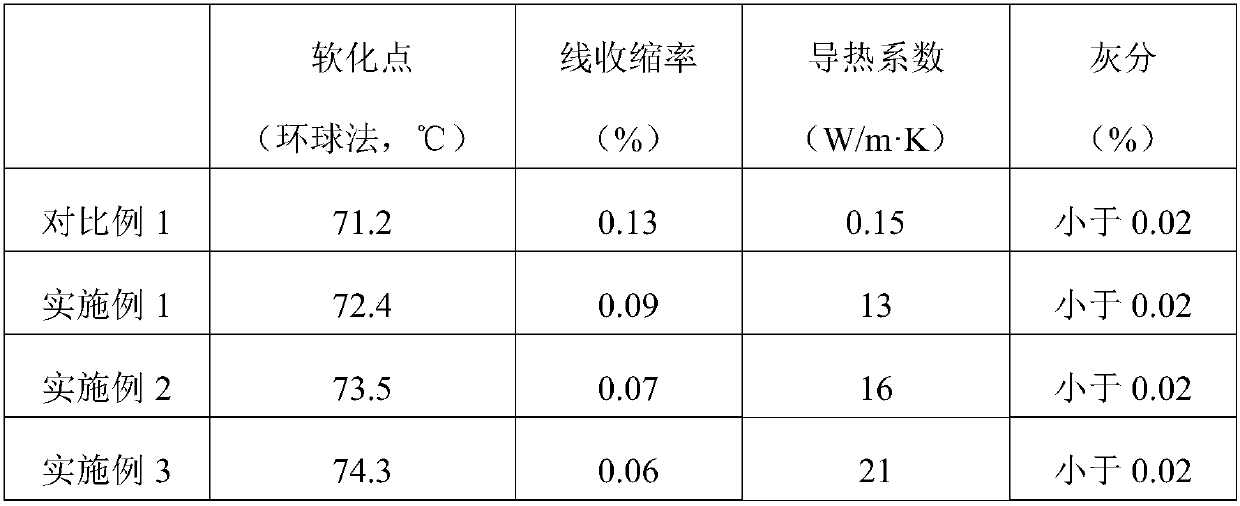

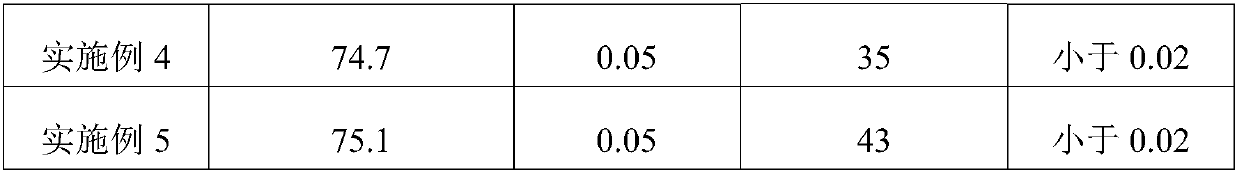

Padding type investment casting wax based on lipophilic micro graphite and preparation method of padding type investment casting wax

An investment casting and lipophilic technology, applied in the direction of casting molding equipment, etc., can solve the problems of affecting the reaction accuracy of castings, affecting product quality, poor thermal conductivity, etc., achieve small ash content, meet high dimensional accuracy and high surface quality, The effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preferably, the preparation method of lipophilic micron graphite comprises the following steps:

[0030] 1) adding micron graphite into water for ultrasonic dispersion, drying to obtain micron graphite powder;

[0031] 2) adding micron graphite powder into an organic solvent, then adding an oily wetting agent, ultrasonically dispersing, and drying to obtain lipophilic micron graphite.

[0032] Preferably, in step 1) of the method for preparing lipophilic micron graphite, the mass ratio of micron graphite to water is (1-10): (90-99); the temperature of the water is 60-70°C, and the ultrasonic dispersion time is 20 ~30min; the drying temperature is 110~130℃, and the drying time is 12~24h.

[0033] Preferably, in step 1) of the method for preparing lipophilic micron graphite, the micron graphite is micron cryptocrystalline graphite.

[0034] Preferably, in step 2) of the method for preparing lipophilic micron graphite, the mass ratio of micron graphite powder, organic so...

preparation Embodiment 1

[0046] 1) Add 10 parts by mass of cryptocrystalline graphite with a particle size of 30 microns to 90 parts by mass of water (at a temperature of 70°C) for ultrasonic dispersion for 30 minutes to remove acid radical ions and metals remaining during the processing of micron graphite ion, filtered, and baked in an oven at 130°C for 24 hours to obtain micron graphite powder;

[0047] 2) Add 10 parts by mass of micron graphite powder to 90 parts by mass of cyclohexane, add 1 part by mass of paraffin oil, ultrasonically disperse for 60 minutes, filter, and bake in an oven at 90°C for 8 hours to remove the organic solvent , to obtain lipophilic micron graphite.

[0048] Add 10 parts by mass of lipophilic micron graphite obtained by the above preparation method to 90 parts by mass of paraffin, and ultrasonically disperse at 100° C. for 60 minutes to obtain a dispersion. After testing, the dispersion maintains good dispersion stability without delamination after 800 high and low temp...

preparation Embodiment 2

[0050] The preparation method is the same as the preparation example 1 of lipophilic micron graphite, the only difference is that the organic solvent is acetone. After testing, the dispersion maintains good dispersion stability without delamination after 800 high and low temperature cycles (20°C-100°C-20°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com