A kind of preparation method of ice cream powder

A technology of ice cream powder and ice cream, which is applied in the field of preparation of ice cream powder, and can solve problems such as unfavorable health, non-compliance, and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

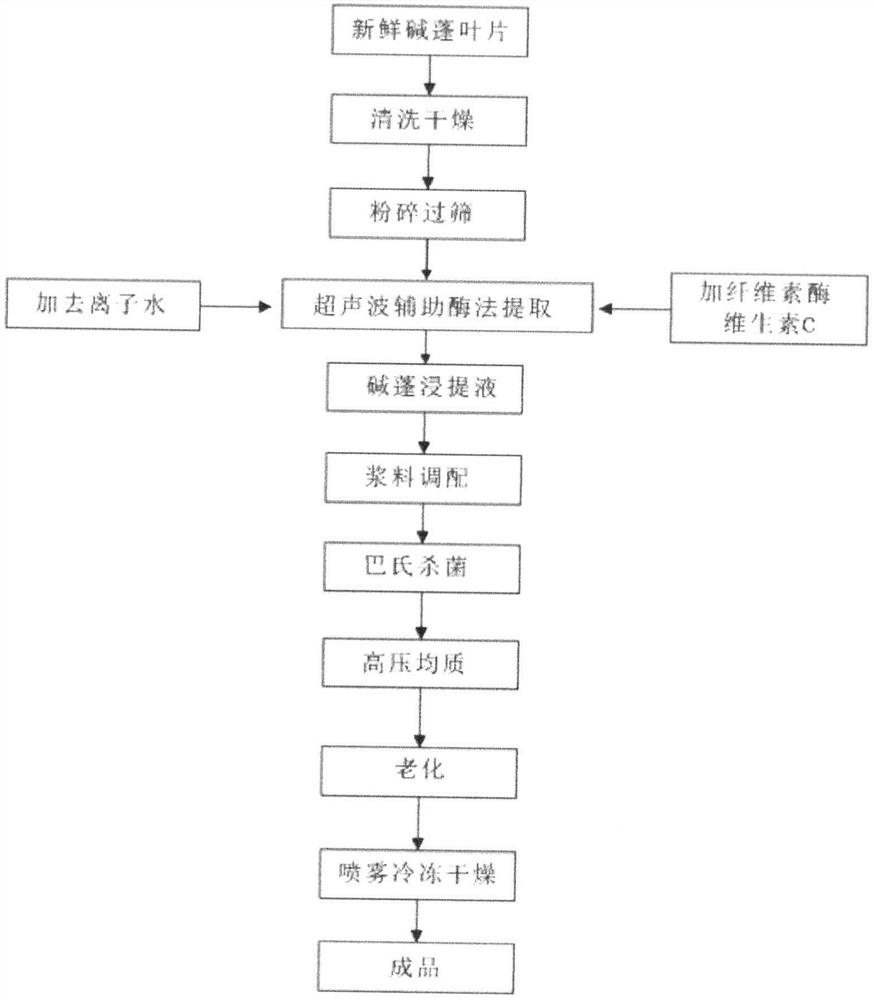

[0041] (1) Preparation of Suaeda salsa extract: collect fresh Suaeda salsa leaves, wash 2 times, dry at 30°C, pulverize, and pass through a 20-mesh sieve; add deionized water according to the mass ratio of material to liquid at 1:20, and add 2% (w / w) cellulase, add 0.05% vitamin C, enzymatic hydrolysis time 20min, enzymatic hydrolysis temperature 30°C, ultrasonic power 50w, extraction times 2 times, combine extracts; filter and set aside;

[0042] (2) A heat-clearing and stagnant ice cream, which is characterized in that it is composed of the weight ratio of the following raw materials: 40 parts of soybean powder, 10 parts of skimmed milk powder, 12 parts of non-dairy creamer, 10 parts of lecithin, and 15 parts of whey powder 5 parts of white granulated sugar, 0.02 part of tamarind gum, 0.02 part of guar gum, 0.2 part of sucrose fatty acid ester, 200 parts of Suaeda salsa extract;

[0043] (3) Preparation of ice cream slurry: get 40 parts of soybean powder, 10 parts of skimmed...

Embodiment 2

[0051] (1) Preparation of Suaeda salsa extract: collect fresh Suaeda salsa leaves, wash 2 times, dry at 40°C, pulverize, and pass through a 30-mesh sieve; add deionized water according to the mass ratio of material to liquid at 1:40, and add 3% (w / w) cellulase, add 0.07% vitamin C, enzymatic hydrolysis time 25min, enzymatic hydrolysis temperature 40°C, ultrasonic power 100w, extraction times 2 times, combine extracts; filter and set aside;

[0052] (2) A heat-clearing and stagnant ice cream, characterized in that it is composed of the following raw materials in parts by weight: 45 parts of soybean powder, 15 parts of skimmed milk powder, 15 parts of non-dairy creamer, 10 parts of lecithin, and 15 parts of whey powder 7 parts of white granulated sugar, 0.1 part of tamarind gum, 0.1 part of guar gum, 0.1 part of sucrose fatty acid ester, 260 parts of Suaeda salsa extract;

[0053] (3) Preparation of ice cream slurry: get 45 parts of soy flour, 15 parts of skimmed milk powder, 7 ...

Embodiment 3

[0061] (1) Preparation of Suaeda salsa extract: collect fresh Suaeda salsa leaves, wash 3 times, dry at 50°C, pulverize, and pass through a 40-mesh sieve; add deionized water according to the mass ratio of material to liquid at 1:50, and add 4% (w / w) cellulase, adding 0.08% vitamin C, enzymolysis time 30min, enzymolysis temperature 50°C, ultrasonic power 200w, extraction times 2 times, combined extracts; filtered for later use;

[0062] (2) A heat-clearing and stagnant ice cream, characterized in that it is composed of the following raw materials in parts by weight: 50 parts of soybean powder, 15 parts of skimmed milk powder, 15 parts of non-dairy creamer, 15 parts of lecithin, and 20 parts of whey powder 10 parts of white granulated sugar, 0.5 part of tamarind gum, 0.5 part of guar gum, 0.5 part of sucrose fatty acid ester, 300 parts of Suaeda salsa extract;

[0063] (3) Preparation of ice cream slurry: get 50 parts of soy flour, 15 parts of skimmed milk powder, 10 parts of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com