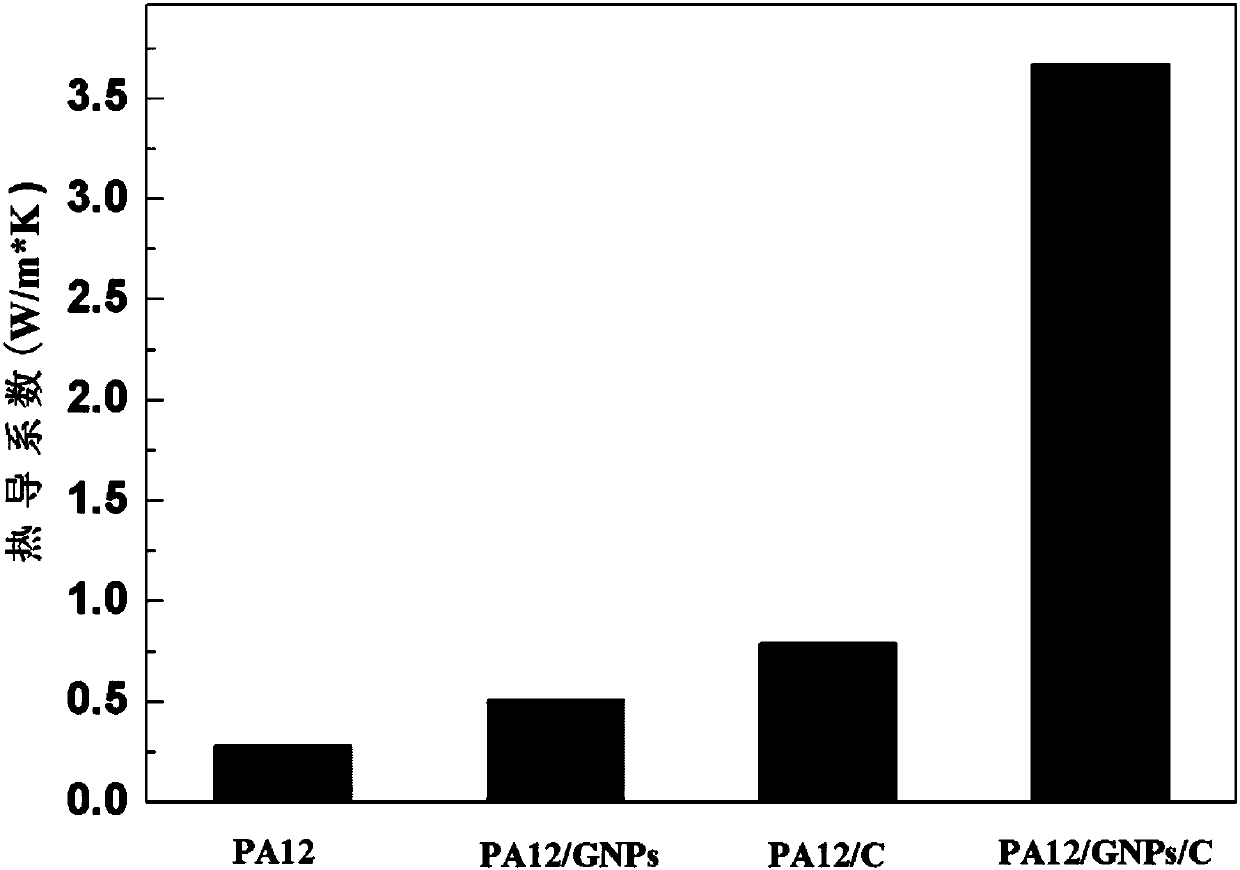

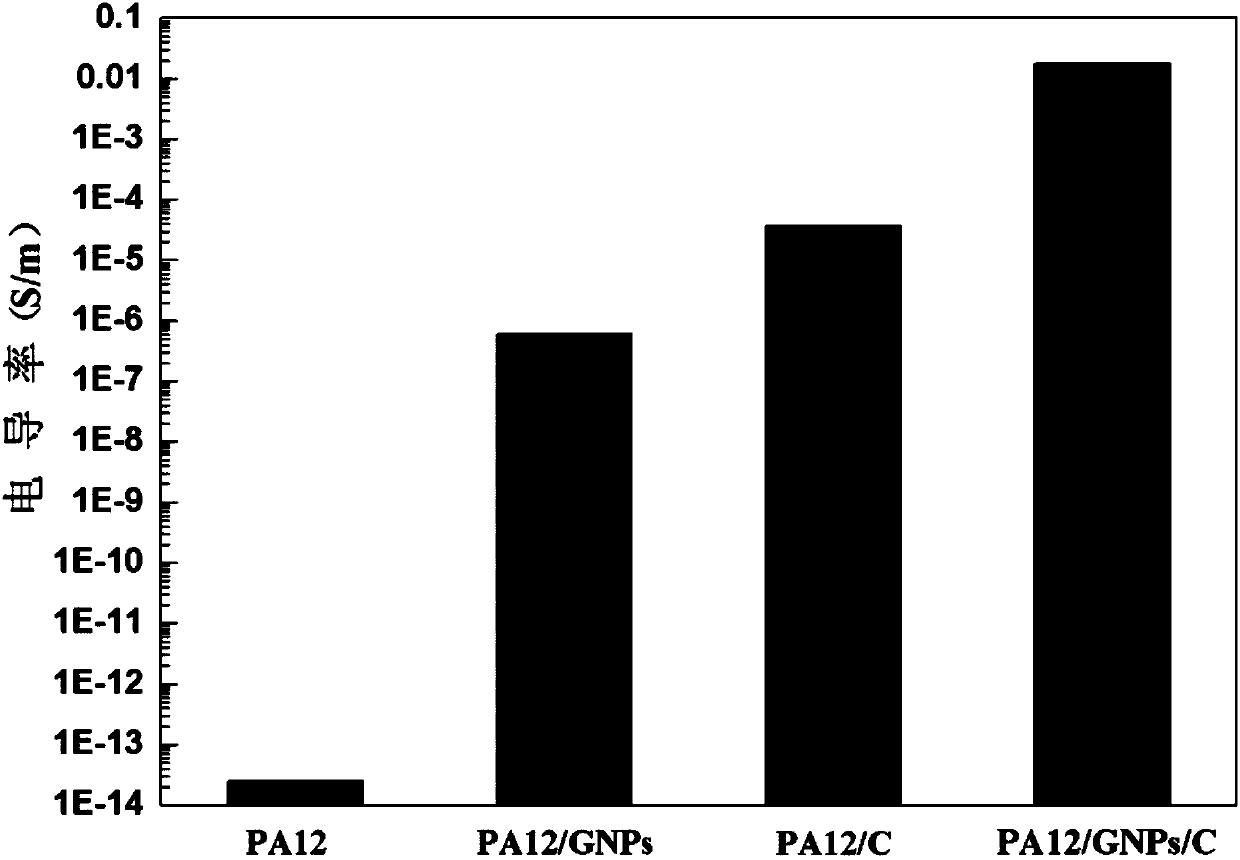

Nylon/graphene/carbon fiber composite powder and preparation method thereof, and application of composite powder to selective laser sintering technology

A composite powder, graphene technology, applied in chemical instruments and methods, heat exchange materials, additive processing, etc., can solve the problems of limited application of molded parts, poor electrical and thermal conductivity, etc., to achieve low cost, improved mechanical properties, laser low power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) First, the graphene is sieved through a sieving machine to obtain graphene powder with a particle size of 10-80 μm.

[0059] (2) Weigh 870g nylon 12 powder, 15g graphene powder, 100g carbon fiber powder, 10g fumed silica and 5g antioxidant 168.

[0060] (3) Graphene and hexadecanoyl amidopropyltrimethylammonium chloride are added in 100g n-propanol with the mass ratio of 1:1, ultrasonic vibration 2-4h, obtain modified graphene dispersion liquid;

[0061] (4) After adding 870g nylon to 4500g ethanol and ethanol bisstearamide (the quality of ethanol bisstearamide is 0.1% of the nylon quality) mixed solution, place it in an autoclave, and with the improved product obtained in step (3) Mix the graphene dispersion liquid evenly, add 0.05g vinyltriethoxysilane, feed nitrogen to pressurize to 1MPa, and stir at high speed (630rpm). Raise the temperature to 145°C and keep it warm for 1 hour until the nylon 12 is completely dissolved. After complete dissolution, the high pr...

Embodiment 2

[0086] (1) First, the graphene is sieved through a sieving machine to obtain graphene powder with a particle size of 10-80 μm.

[0087] (2) Weigh 955g nylon 12 powder, 15g graphene powder, 15g carbon fiber powder, 10g fumed silica and 5g antioxidant 168.

[0088] (3) Graphene and cetyl amidopropyltrimethylammonium chloride are added in 100g n-propanol with the mass ratio of 1:1, ultrasonic vibration 2-4h, obtain modified graphene dispersion liquid;

[0089] (4) After adding 955g nylon to 4500g ethanol and ethanol bis stearamide (the quality of ethanol bis stearamide is 0.1% of the nylon quality) mixed solution, place it in an autoclave, and with the improved product obtained in step (3) Mix the graphene dispersion liquid evenly, add 0.05g vinyltriethoxysilane, feed nitrogen to pressurize to 1MPa, and stir at high speed (630rpm). Raise the temperature to 145°C and keep it warm for 1 hour until the nylon 12 is completely dissolved. After complete dissolution, the high pressure...

Embodiment 3

[0094] (1) First, the graphene is sieved through a sieving machine to obtain graphene powder with a particle size of 10-80 μm.

[0095] (2) Weigh 860g nylon 12 powder, 25g graphene powder, 100g carbon fiber powder, 10g fumed silica and 5g antioxidant 168.

[0096] (3) Graphene and cetyl amidopropyltrimethylammonium chloride are added in 100g n-propanol with the mass ratio of 1:1, ultrasonic vibration 2-4h, obtain modified graphene dispersion liquid;

[0097] (4) After adding 860g nylon to 4500g ethanol and ethanol bisstearamide (the quality of ethanol bisstearamide is 0.1% of the nylon quality) mixed solution, place it in an autoclave, and with the modified product obtained in step (3) Mix the graphene dispersion liquid evenly, add 0.05g vinyltriethoxysilane, feed nitrogen to pressurize to 1MPa, and stir at high speed (630rpm). Raise the temperature to 145°C and keep it warm for 1 hour until the nylon 12 is completely dissolved. After complete dissolution, the high pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com