Ultraviolet curing UV ink jet ink as well as preparation method and application thereof

A technology of inkjet ink and ultraviolet light, which is applied in applications, inks, household appliances, etc., can solve the problems of cumbersome process flow, high quality requirements, and complicated operation process, and achieve simple processing technology, low energy consumption, and no pollution to the environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Preparation of hydrocarbon-terminated carboxyl silicone oil:

[0052] In parts by weight, add 65 parts of double-ended hydrogen silicone oil, 35 parts of β-carboxyethyl acrylate, and 0.05 parts of Karstedt catalyst into the reaction vessel, heat it to 60-145°C, and monitor it with an infrared spectrometer until Si-H The main bond disappears, the whole reaction time is 6-8 hours, and the hydrocarbon-terminated carboxyl silicone oil is obtained from the discharge.

[0053] Preparation of main body UV resin:

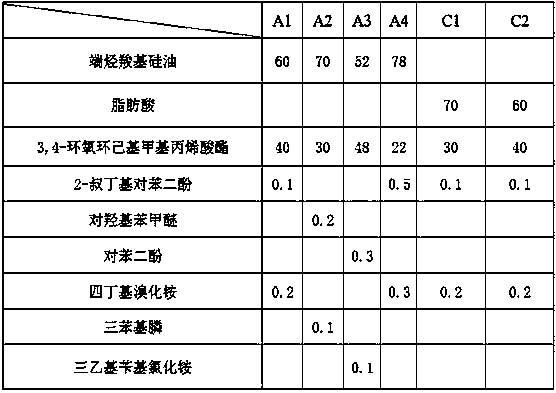

[0054] According to the formula shown in Table 1, add hydrocarbon-terminated carboxyl silicone oil, 3,4-epoxycyclohexyl methacrylate, polymerization inhibitor, and catalyst into the reaction vessel, heat to 85-135°C, and control the reaction temperature at 85- 135°C, keep warm until the acid value is less than 3mgKOH / g, the whole reaction time is 3-8 hours, and the main UV resin is obtained by discharging;

[0055] Table 1 A1 ~ A4, C1-C2 main body UV resin (parts b...

Embodiment 1-6 and comparative example 1-2

[0058] According to the formula shown in Table 2, the main UV resin, triglycidyl isocyanurate, 3,4-epoxycyclohexyl methacrylate, N-vinyl caprolactam, dipentaerythritol hexaacrylate, stirred simultaneously Add photoinitiator and silane coupling agent, then add pigment while stirring, disperse at high speed for 1 hour, remove air bubbles in vacuum, filter, and obtain. The obtained UV-cured UV inkjet ink was sprayed onto the 3D curved cover glass of the mobile phone, and its various properties were tested. The results are shown in Table 2.

[0059] Table 2 The composition and performance results of each component of the embodiment and the comparative example

[0060]

[0061]As can be seen from the results of the examples and comparative examples in Table 2, the main body UV resin of the present invention is modified by organosilicon to obtain the alicyclic epoxy acrylate oligomer modified by organosilicon, and the introduction of its organosilicon segment greatly improves the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com