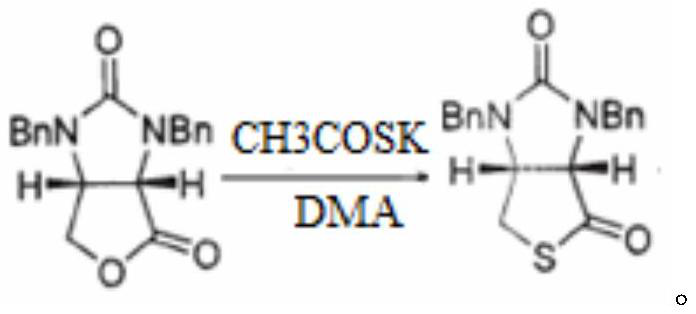

A kind of method for preparing d-biotin thiolactone intermediate

A technology for intermediates and thiolactones is applied in the field of preparing D-biotin thiolactone intermediates, which can solve the problems of high production cost, complicated operation, reduced product purity and the like, and achieve the effects of reduced preparation cost and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

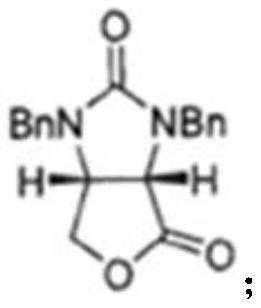

Embodiment 1

[0022] a) Add 116.0 g of the lactone intermediate and 50.0 g of potassium thioacetate into the reaction flask, stir and heat up until the reaction system is in a completely molten state, and then keep stirring for 4 to 5 hours;

[0023] b) Cool down to 50-60°C, add 250mL deionized water;

[0024] c) cooling the temperature of the reaction system to 0-5°C while stirring, and then keeping the temperature and continuing to stir for 2-3 hours;

[0025] d) Filtrate, collect the solid, wash with 80 mL of deionized water and dry under reduced pressure at 60°C to obtain 112.2 g of the D-biotinthiolactone intermediate with a mass yield of 97% (relative to the lactone intermediate body), the HPLC purity was 99.6%.

Embodiment 2

[0027] a) Add 50.0 g of the lactone intermediate and 25.0 g of potassium thioacetate into the reaction flask, stir and heat up until the reaction system is in a completely molten state, and then keep stirring for 2 to 3 hours;

[0028] b) Cool down to 70-80°C, add 200mL deionized water;

[0029] c) cooling the reaction system to 5-10°C while stirring, and then keeping the temperature and continuing to stir for 4-5 hours;

[0030] d) Filtrate, collect the solid, wash with 50 mL of deionized water and dry under reduced pressure at 60°C to obtain 47.6 g of the D-biotinthiolactone intermediate with a mass yield of 95% (relative to the lactone intermediate body), the HPLC purity was 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com