Preparation method of waterborne PES (polyether sulfone) coating

A water-based coating, polyethersulfone technology, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve the problems of large particle size of polyethersulfone particles, long process, low product purity, etc., and achieve stable performance and small particle size. , the effect of excellent application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

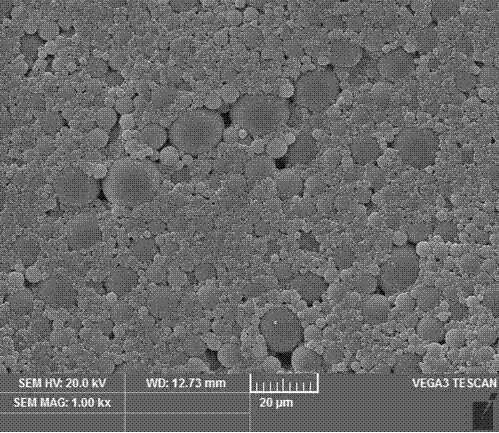

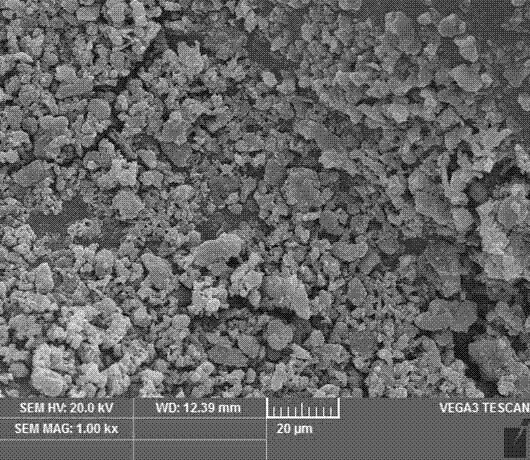

Embodiment 1

[0028] Taking a 100L polymerization kettle as an example, prepare raw materials according to the following quality: 4,4-dichlorodiphenyl sulfone (13.04Kg), bisphenol S (5.22Kg), sodium carbonate (2.4Kg), N-methylpyrrolidone (20Kg ), toluene (4Kg).

[0029] After weighing the above-mentioned substances according to the molar ratio, add raw materials bisphenol S, 4,4-dichlorodiphenyl sulfone, dehydrating agent toluene, solvent N-methylpyrrolidone into the reactor, pass inert gas protection, and open Stir, heat the reactor to 120°C, add salt-forming agent sodium carbonate after all the raw materials are dissolved, raise the temperature of the reactor to 160°C for reflux reaction for 2 hours and 30 minutes, release toluene and generate water, then heat the reactor The polymerization reaction was carried out at 200° C. for 3 hours, and the polymerization reaction was terminated.

[0030] After the polymerization reaction is completed, reduce the temperature of the jacket of the po...

Embodiment 2

[0033] With reference to Example 1 for the specific method, the difference with Example 1 is only: prolonging the reflux reaction time for 30 minutes, prolonging the polymerization reaction time for 30 minutes; the average particle diameter of the obtained polyethersulfone water-based coating particles is 8.7 microns, and the particle size distribution range is 1~ 20 microns.

Embodiment 3

[0035]The specific method is with reference to Example 1, and the difference with Example 1 is only: shorten the reflux reaction time for 30 minutes, and shorten the polymerization reaction time for 30 minutes; 20 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com