Oleaginous microalgae having an LPAAT ablation

A technology of microalgal cells and cell oil, applied in DNA/RNA fragments, microorganisms, single-celled algae, etc., can solve problems such as cell division inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

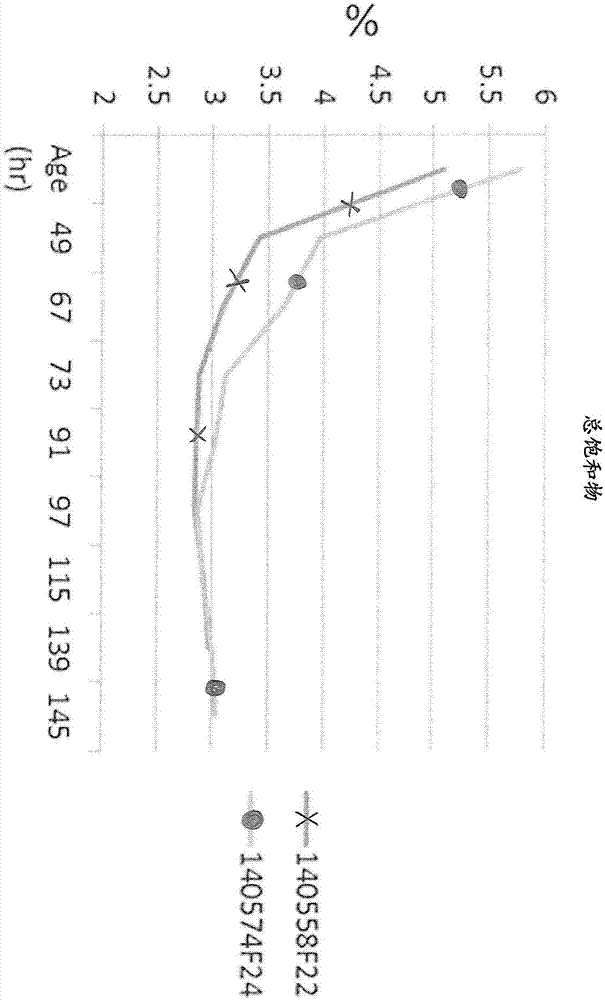

[0318] Example 1: Fatty acid analysis by fatty acid methyl ester detection

[0319] Prepare lipid samples from dried biomass. Resuspend 20-40mg of dry biomass in 2mL containing 5% H 2 SO 4 And add 200μl of toluene containing an appropriate amount of suitable internal standards (C19:0). The mixture was sonicated briefly to disperse the biomass, and then heated at 70°C-75°C for 3.5 hours. Add 2mL of heptane to extract fatty acid methyl esters, followed by 2mL of 6% K 2 CO 3 (Aqueous solution) to neutralize acid. The mixture was stirred vigorously, and a part of the upper layer was transferred to 2 SO 4 The (anhydrous) vial is used for gas chromatographic analysis using standard FAME GC / FID (Fatty Acid Methyl Ester Gas Chromatographic Flame Ionization Detection) method. This method is used to determine the fatty acid profile reported below.

example 2

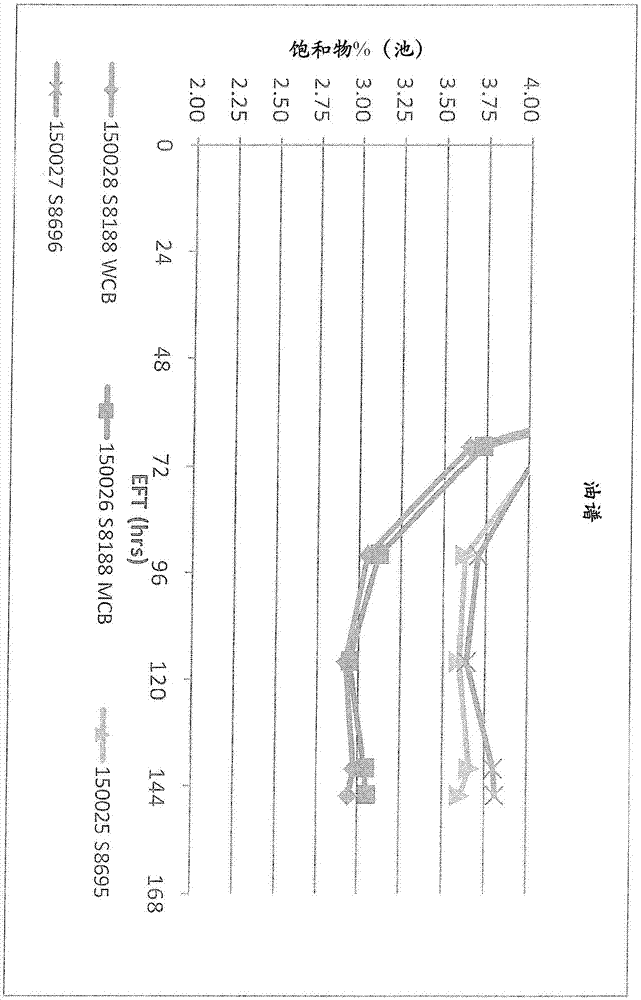

[0320] Example 2: Engineering the microorganisms for fatty acid and sn-2 profiles to increase lauric acid through exogenous LPAAT expression

[0321] This example describes the use of multiple recombinant polynucleotides encoding coconut 1-acyl-sn-glycerol-3-phosphate acyltransferase (Cn LPAAT) to engineer a microorganism. The fatty acid profile and sn- 2 spectrum is already rich in lauric acid.

[0322] According to the bioprojectile transformation method described in PCT / US 2009 / 066141, PCT / US 2009 / 066142, PCT / US 2011 / 038463, PCT / US2011 / 038464 and PCT / US 2012 / 023696, the plasmid construct pSZ1283 was initially used. The classically mutagenic strain of transformed mulberry-type Prototheca (UTEX 1435), strain A. The pSZ1283 described in PCT / US 2011 / 038463, PCT / US2011 / 038464, and PCT / US 2012 / 023696 (incorporated herein by reference) comprises Wright calyx distance flower (Cuphea wrightii) FATB2 (CwTE2) thioesterase (SEQ ID NO: 10); the 5'(SEQ ID NO: 1) and 3'(SEQ ID NO: 2) homolog...

example 3

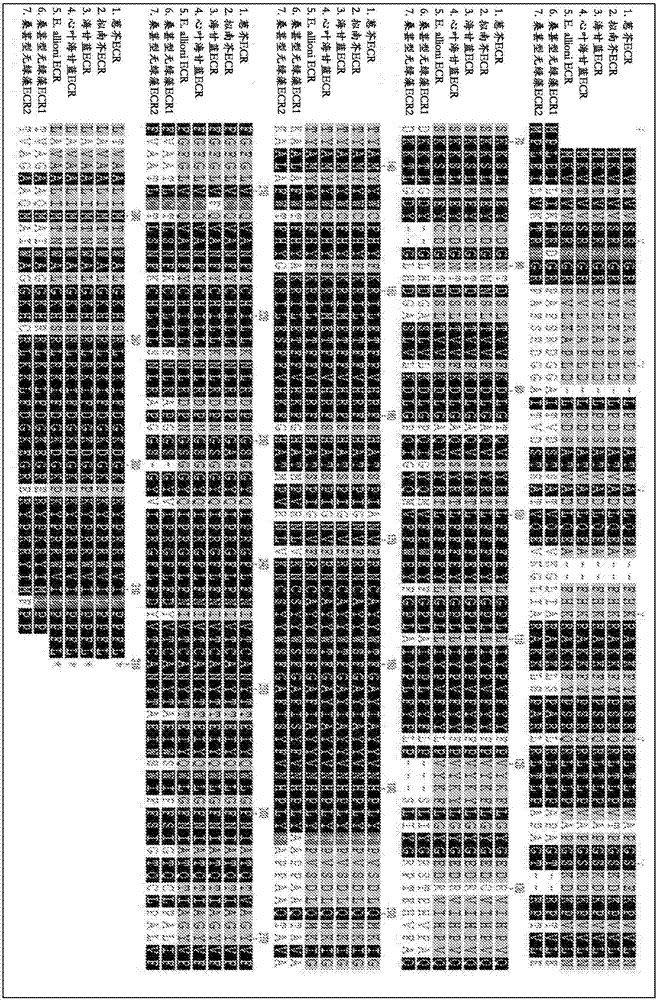

[0336] Example 3: Analysis of region-specific spectrum

[0337] LC / MS TAG distribution analysis was performed using a Shimadzu Nexera ultra-high performance liquid chromatography system coupled to a Shimadzu LCMS 8030 triple quadrupole mass spectrometer equipped with an APCI source. The system includes a SIL -30AC autosampler, two LC-30AD pumps, a DGU-20A5 online degasser and a CTO-20A column thermostat. The data was collected using a Q3 scan of m / z350-1050 at a scan speed of 1428u / sec in the positive ion mode where the CID gas (argon) pressure was set to 230kPa. The APCI, desolvation tube, and heating block temperature were set to 300°C, 250°C, and 200°C, respectively, the spray and drying gas flow rates were 3.0L / min and 5.0L / min, and the interface voltage was 4500V. The oil sample was dissolved in dichloromethane-methanol (1:1) to a concentration of 5 mg / mL, and 0.8 μL of the sample was injected into Shim-pack XR-ODS III maintained at 30°C (2.2μm, 2.0×200mm). At 0.48mL / min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com